Material demanding method for auxiliary material object disc of ultra-high-speed cigarette making machine

A cigarette machine, ultra-high-speed technology, applied in the fields of tobacco, cigarette manufacturing, food science, etc., can solve the problems affecting the production efficiency of enterprises, high-speed consumption of raw and auxiliary materials, etc., to achieve the effect of automation, improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Related technical explanation:

[0045] 1. Finished cigarettes: every 20 cigarettes is a small pack, every 10 small packs is one pack, every 50 packs is one pack, and every 30 packs is a pallet.

[0046]2. Dimensions of auxiliary material wooden pallet: 1000*1500*150mm.

[0047] 3. M8 ultra-high-speed cigarette making machine: PROTOS-M8 ultra-high-speed cigarette making machine is a world-class equipment imported from HAUNI company. Its production speed can reach up to 20,000 cigarettes / min, and it has a high degree of automation. The cigarette making machine is divided into 5 parts, which are BD paper feeding device, VE feeding device, SE cigarette rod rolling and forming device, MAX filter tip forming device and VARIOS cigarette conveying / storage device.

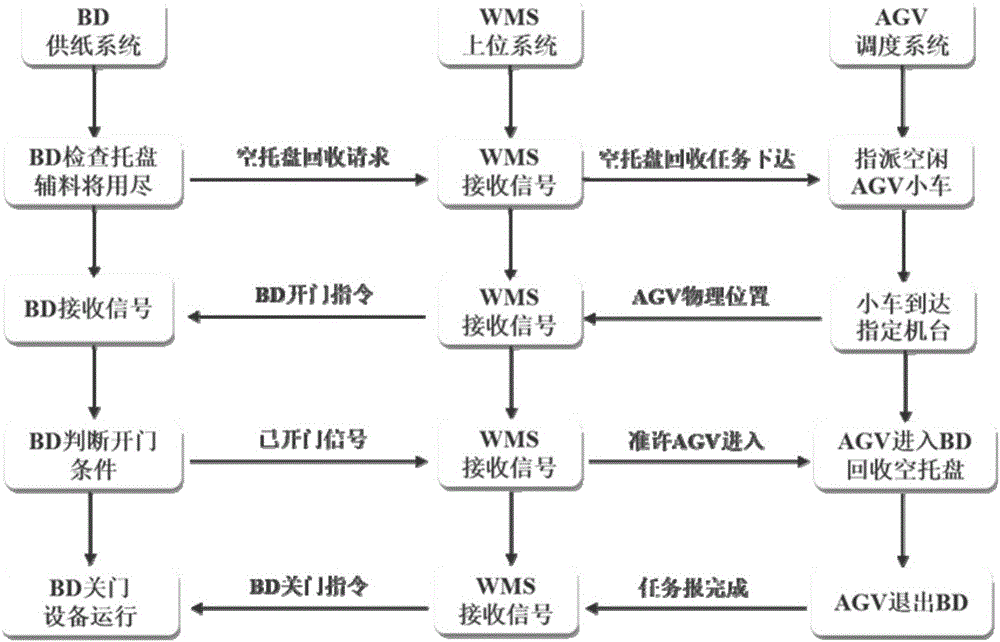

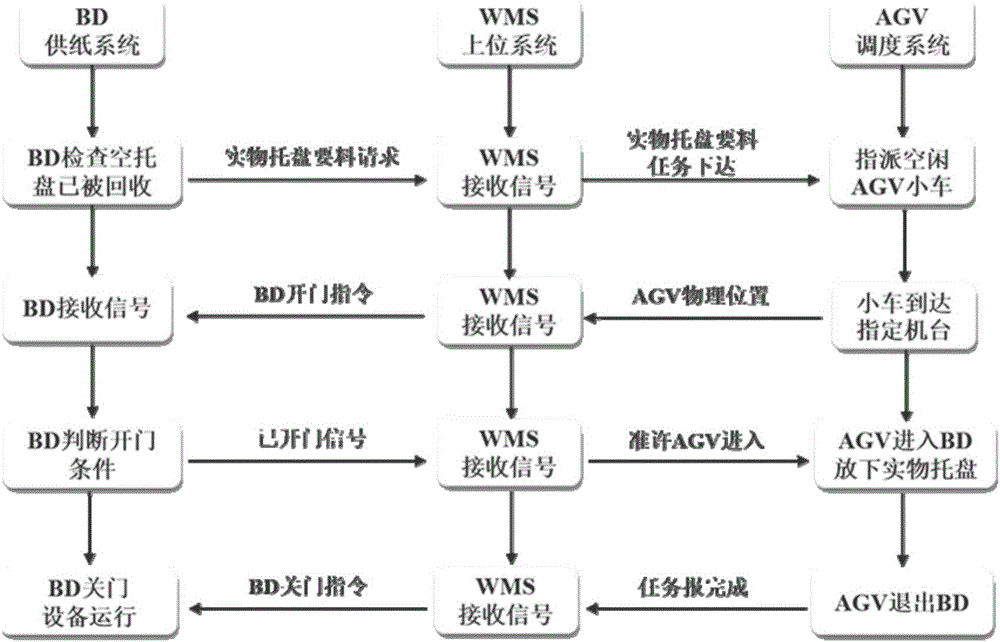

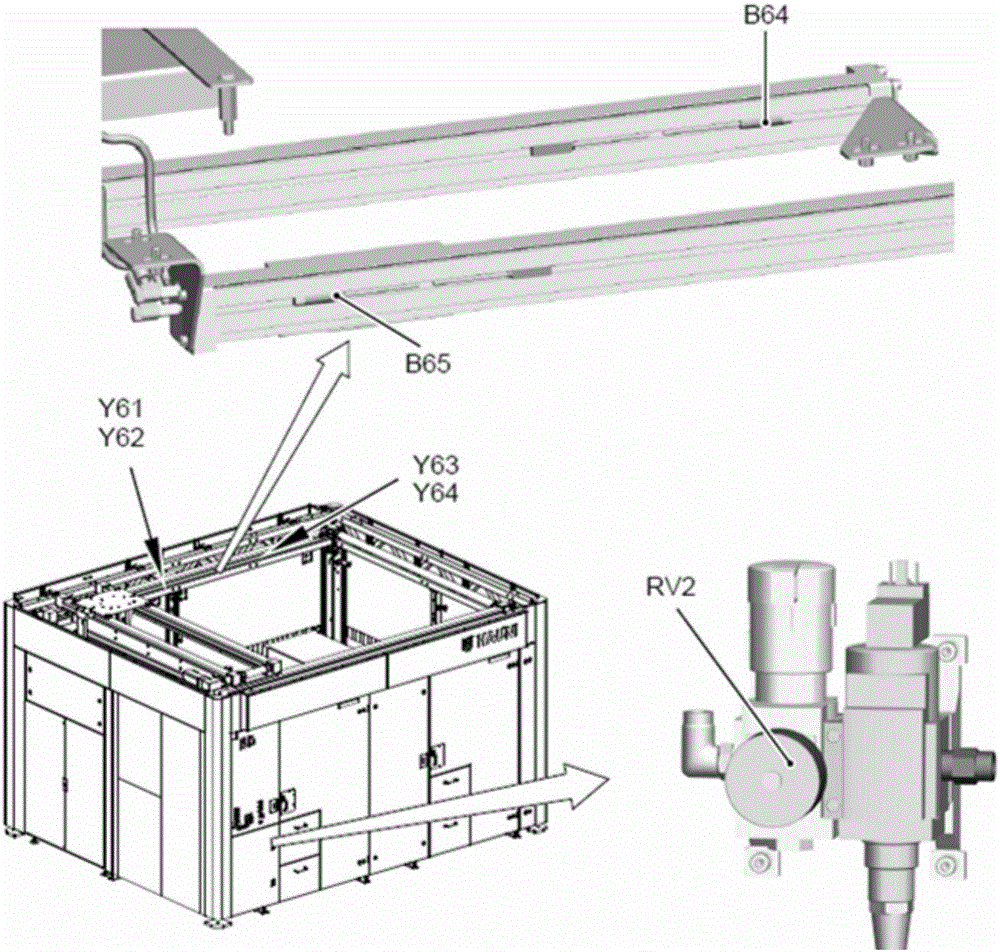

[0048] 4. BD paper feeding device: BD paper feeding device is designed for automatic unloading of raw and auxiliary materials of cigarettes. BD is divided into BOB1 and BOB2, which provide cigarette paper and tipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com