Oven steam cooling system

A steam cooling and oven technology, which is applied in the field of kitchen ovens, can solve the problems of poor steam condensation effect, difficult to clean, damp furniture, etc., and achieve the effects of improving market competitiveness, avoiding steam burns, and reducing steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

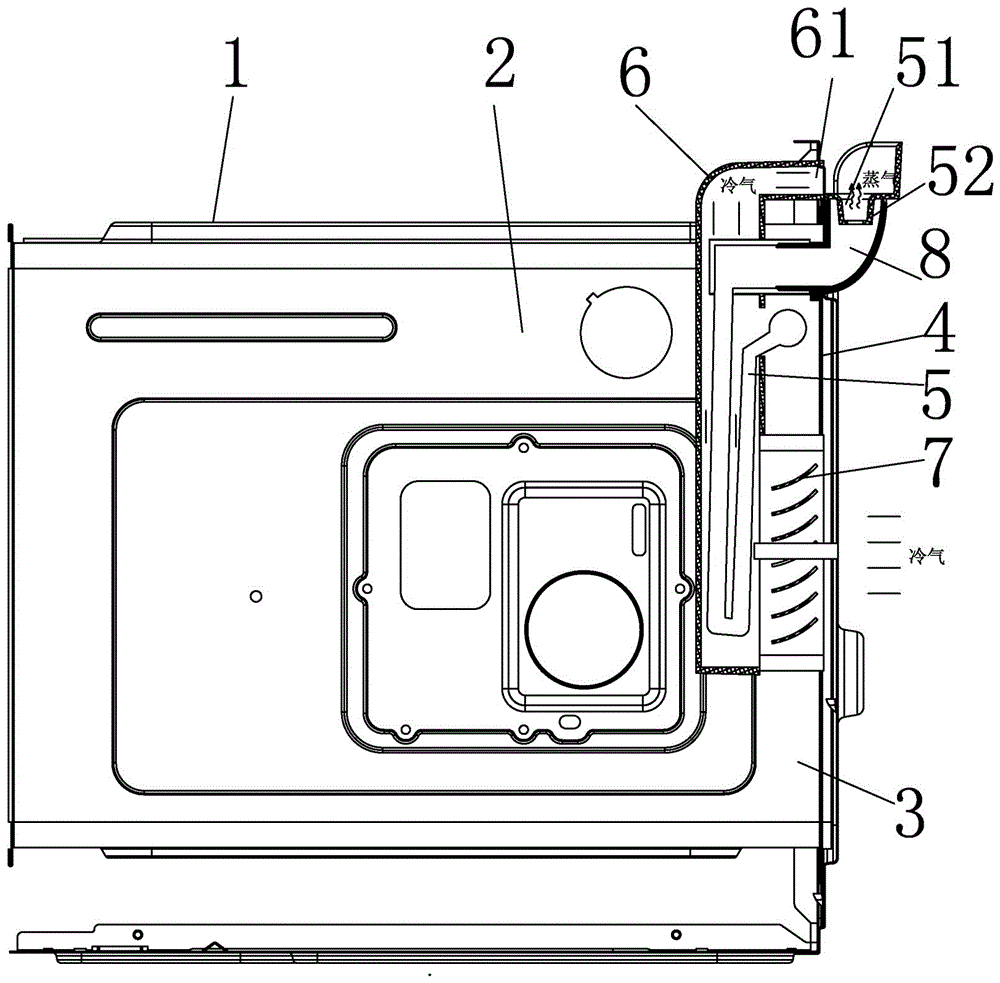

[0012] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A steam cooling system for an oven, which includes an outer shell 1 and an inner container 2, an installation cavity 3 is arranged between the outer shell 1 and the inner container 2, and a steam generator 4 is arranged in the installation cavity 3 to connect with the inner container 2, and is characterized in that: The inner tank 2 is provided with an exhaust pipe 5 to communicate with the outside world, the exhaust pipe 5 is covered by the condensation box 6, the condensation box 6 is provided with a ventilation device 7, and the ventilation device 7 leads into the condensation box 6 The air forcibly cools the exhaust pipe 5 .

[0013] The exhaust pipe 5 is made of aluminum and extends in the condensation box 6 in a meandering manner.

[0014] The ventilation device 7 is a fan arranged on the air inlet of the condensation box 6 .

[0015] The air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com