Tail end swinging joint driving mechanism

A driving mechanism and joint technology, which is applied in the field of swing joint drive mechanism, can solve the problems that the slack wire cannot be instantly changed into the tension wire, the position and posture of the end swing joint are unstable, and the processing and assembly are complicated, so as to achieve precise operation and simple structure , the effect of reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

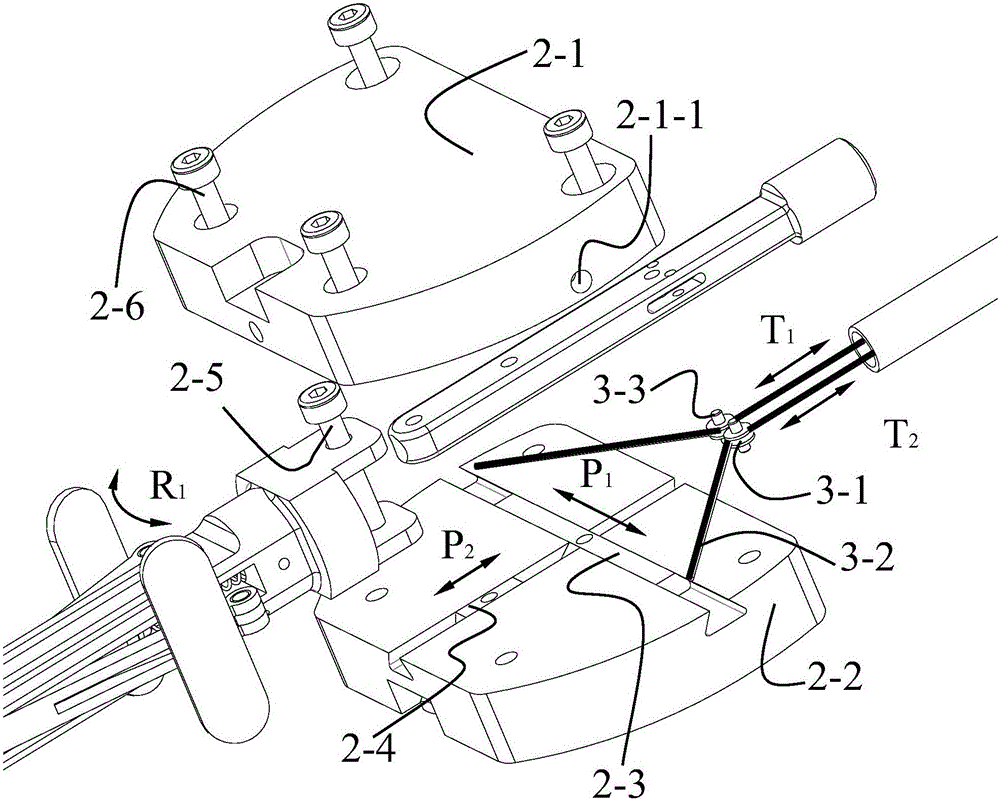

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

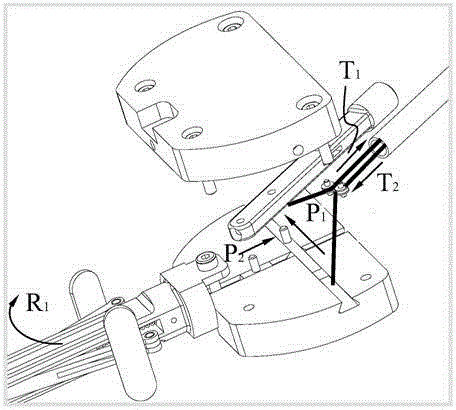

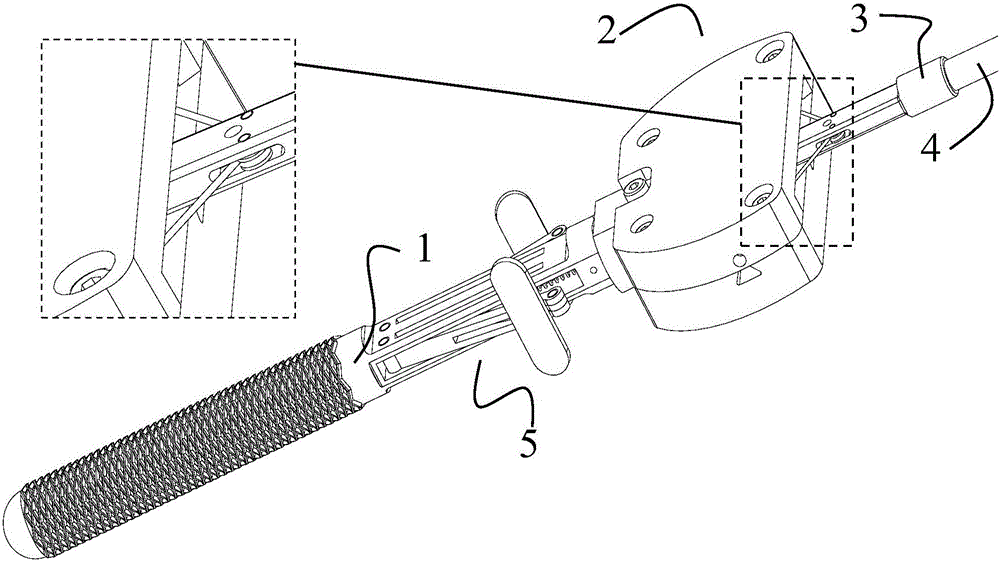

[0019] As shown in the accompanying drawings, the terminal swing joint driving mechanism of the present invention includes a lower bottom plate 2-2, and horizontal dovetail guide grooves 2-2- 1 and the longitudinal dovetail guide groove 2-2-2, the transverse guide rail 2-3 is slidably connected in the transverse dovetail guide groove 2-2-1, so as to realize the transverse dovetail of the transverse guide rail 2-3 on the lower base plate 2-2 Slide left and right in the guide groove 2-2-1. A longitudinal guide rail 2-4 is slidably connected in the longitudinal dovetail guide groove 2-2-2, so as to realize the longitudinal guide rail 2-4 sliding back and forth in the longitudinal dovetail guide groove 2-2-2 of the lower base plate 2-2. A first pin shaft 2-7 is vertically connected to the transverse guide rail 2-3, a second pin sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com