Manufacturing method of paper diaper using antibacterial polypeptide and antibacterial paper diaper thereof

A technology of antibacterial polypeptide and production method, which is applied in the field of antibacterial diapers, can solve the problems of lack of antibacterial and bactericidal functions, and achieve the effect of strong practicability, good effect, and reasonable and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

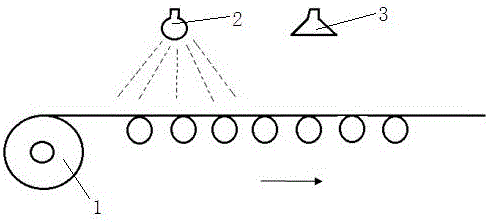

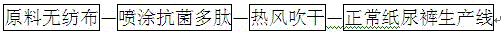

Image

Examples

Embodiment 1

[0038] An antibacterial paper diaper for babies, the production method is as follows:

[0039] 1. Dilute the antibacterial polypeptide raw material to the following concentration: the mass concentration of the antibacterial polypeptide solution is: 0.0005%-0.05%, the temperature and use conditions of the antibacterial polypeptide are 10 degrees Celsius to 130 degrees Celsius, and the pH value is 5-8.

[0040] 2. Spray the above mixed solution evenly on the non-woven fabric (hot-air or hot-rolled non-woven fabric treated with hydrophilic treatment) of the first layer of diapers with a continuous spray dryer, and dry it quickly, and then put this Non-woven fabrics are used in the diaper production line.

[0041] 3. Other production processes of diapers are the same as those of general diapers and changing pads.

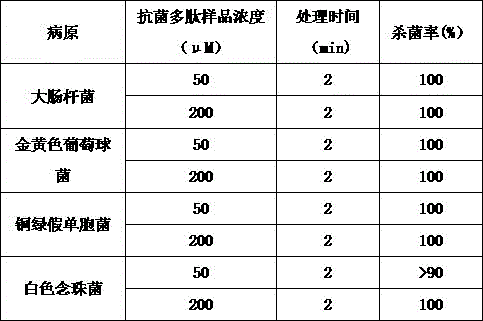

[0042] The detection method is carried out according to the 2002 version of the "Disinfection Technical Specifications" -2.1.11.3.1.

Embodiment 2

[0044] An antibacterial paper diaper for patients, the production method is as follows:

[0045] 1. Dilute the antibacterial polypeptide raw material to the following concentration: the mass concentration of the antibacterial polypeptide solution is: 0.003%--0.07%, the temperature and use conditions of the antibacterial polypeptide are 10 degrees Celsius to 130 degrees Celsius, and the pH value is 5-8.

[0046] 2. Spray the above mixed solution evenly on the non-woven fabric (hot-air or hot-rolled non-woven fabric treated with hydrophilic treatment) of the first layer of diapers with a continuous spray dryer, and dry it quickly, and then put this Non-woven fabrics are used in the diaper production line.

[0047] 3. Other production processes of diapers are the same as those of general diapers and changing pads.

[0048] The detection method is carried out according to the 2002 version of the "Disinfection Technical Specifications" -2.1.11.3.1.

Embodiment 3

[0050] An antibacterial paper diaper for the elderly, the production method is as follows:

[0051] 1. Dilute the antibacterial polypeptide raw material to the following concentration: the mass concentration of the antibacterial polypeptide solution is: 0.0007%--0.06%, the temperature and use conditions of the antibacterial polypeptide are 10 degrees Celsius to 130 degrees Celsius, and the pH value is 5-8.

[0052] 2. Spray the above mixed solution evenly on the non-woven fabric (hot-air or hot-rolled non-woven fabric treated with hydrophilic treatment) of the first layer of diapers with a continuous spray dryer, and dry it quickly, and then put this Non-woven fabrics are used in the diaper production line.

[0053] 3. Other production processes of diapers are the same as those of general diapers and changing pads.

[0054] The detection method is carried out according to the 2002 version of the "Disinfection Technical Specifications" -2.1.11.3.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com