Improved desulphurization device

A desulfurization equipment and wet desulfurization technology, applied in the field of machinery, can solve the problems of large area, high cost, scattered structure, etc., and achieve the effect of reducing the area, reducing the gap, and improving the compactness of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

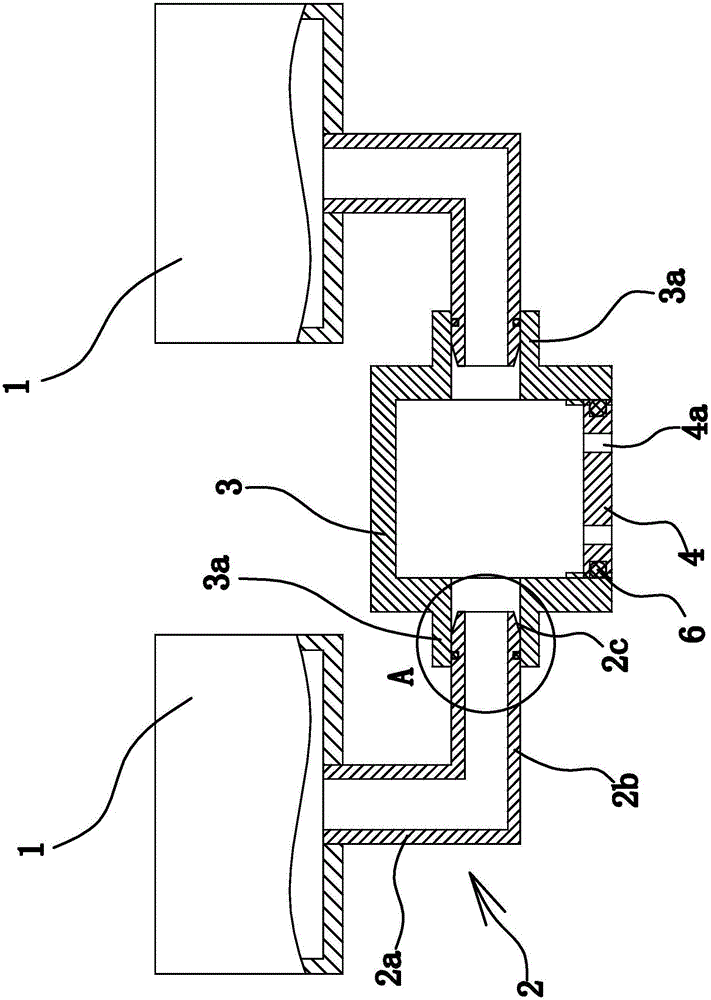

[0025] Such as figure 1 As shown, the improved desulfurization equipment is composed of a wet desulfurization device 1, a gas pipe 2, a connecting pipe 3, a connecting plate 4 and the like. Among them, the wet desulfurization device 1 is an existing product, such as a wet desulfurization device disclosed in the Chinese patent library [application number: 201510796580.4; publication number: CN105268304A], and the bottom of the wet desulfurization device 1 has a flue gas inlet .

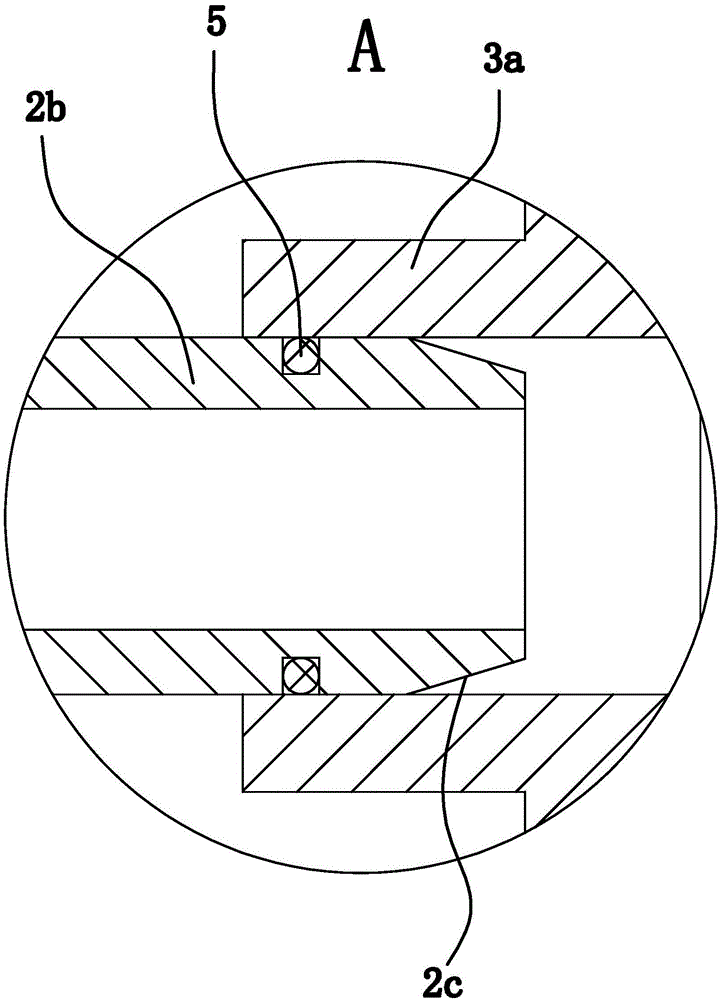

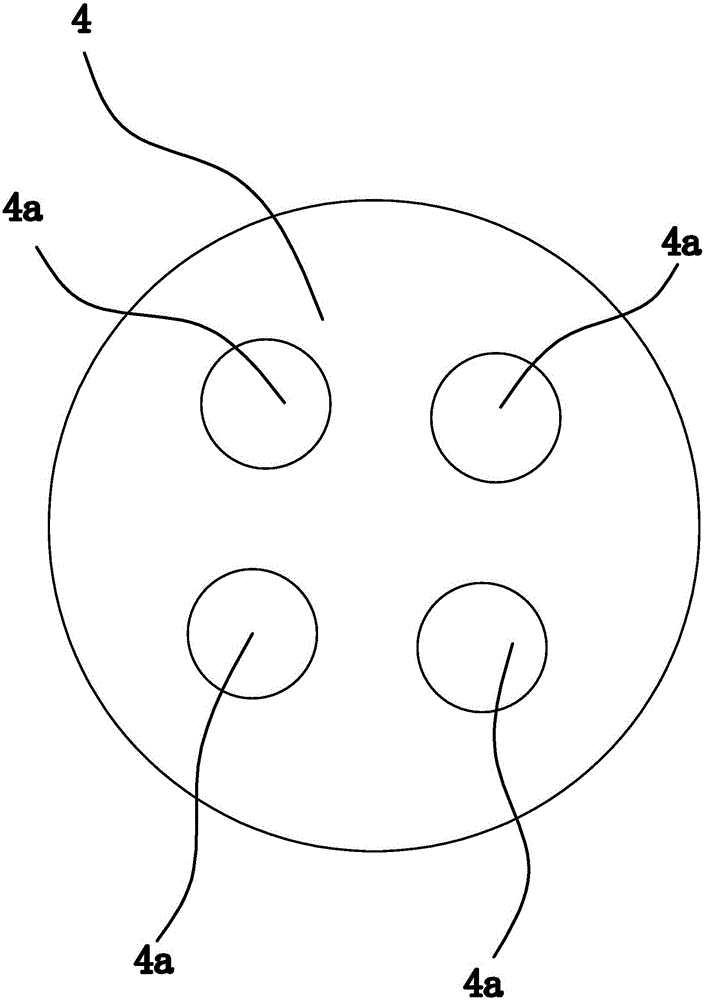

[0026] Specifically, there are two wet desulfurization devices 1 arranged side by side. A gas pipe 2 is provided at the bottom of each wet desulfurization device 1 , each gas pipe 2 is L-shaped, and each gas pipe 2 includes a vertical gas outlet 2 a and a horizontal gas inlet 2 b. Wherein, the two gas outlets 2a communicate with the two flue gas inlets respectively. In this embodiment, the upper end of the gas outlet part 2a is inserted into the flue gas inlet, the outer wall of the gas outlet part ...

Embodiment 2

[0032] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that there is a protruding annular shoulder on the outer wall of the air intake portion 2b, the annular shoulder is coaxial with the air intake portion 2b, and the annular The shoulder abuts against the connecting portion 3a. The sealing structure includes an annular groove on the end surface of the annular shoulder and an annular sealing gasket inside the annular groove. The two ends of the annular gasket respectively abut against the bottom wall of the annular groove and the end surface of the connecting part 3a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com