Intelligent self-cleaning dual-curing coating system

A self-cleaning, dual-curing technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the very high control requirements of reaction conditions, the difficulty of ensuring the uniformity of mixing, and the uniformity of component mixing. impact and other issues, to achieve the effect of reducing technical ability requirements, improving spray gun structural defects, simplifying construction difficulty and construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The described embodiments are only some of the embodiments of the invention. All other embodiments without creative achievements based on the embodiments of the present invention belong to the protection scope of the present invention.

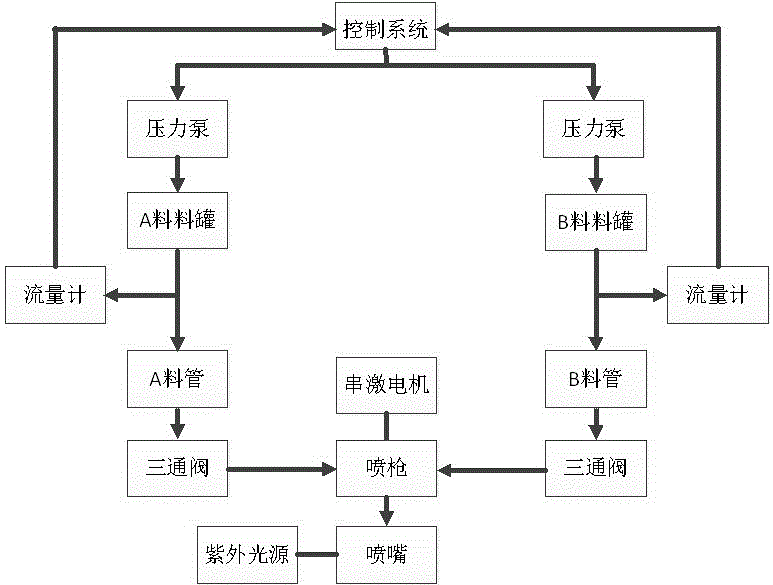

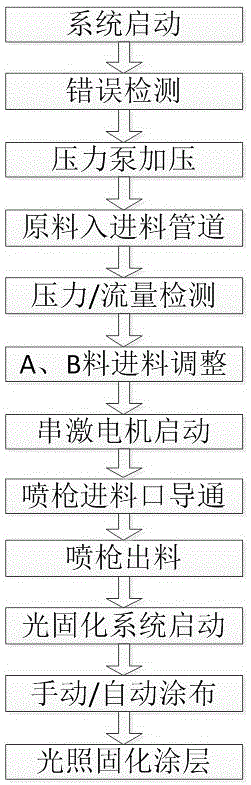

[0029] The intelligent self-cleaning dual-curing coating system of the present invention includes a spray gun, a feeding system, an ultraviolet light source device and a control system, and its system block diagram is as follows figure 1 shown.

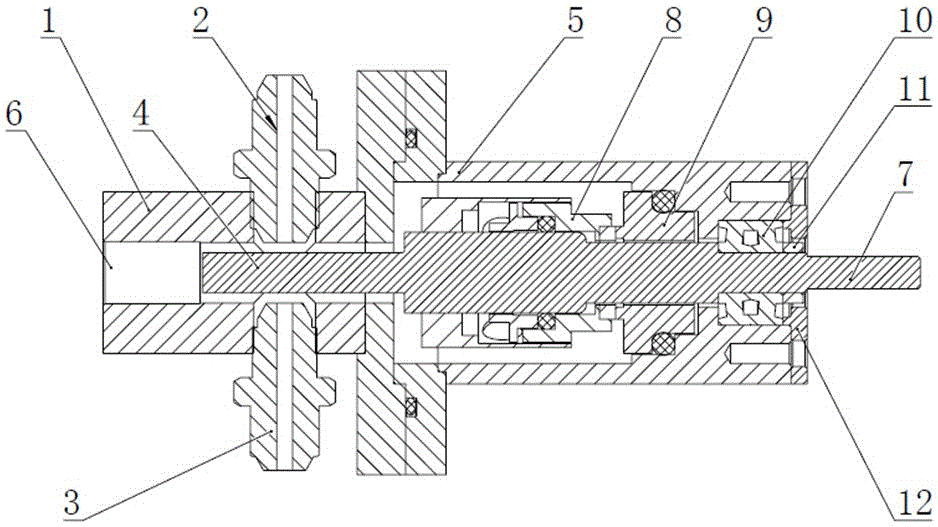

[0030] The spray gun of the system uses a series motor to improve the mixing uniformity of the raw materials. The structure is as follows: figure 2shown. The spray gun is composed of a mixing chamber 1, a material feeding pipe 2, a material feeding pipe 3, a rotor 4 and a sealing chamber 5. There is also a discharge hole 6 on the mixing chamber, which can be directly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com