A preparation method of fiber tape reinforced thermoplastic resin composite pipe

A technology for enhancing thermoplastic and resin composites, which is applied in the field of composite pipes, can solve the problems of poor interface bonding of fiber tape winding composite pipes, and achieves the effects of reasonable equipment structure, simple production method and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

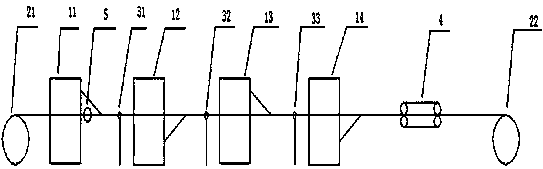

[0028] Such as Figure 1-3 Shown, a kind of preparation method of fiber tape reinforced thermoplastic resin composite pipe of the present invention comprises the steps:

[0029] a. The inner layer core tube is unwound by the unwinding device 21, and the tension force of the unwinding device 21 is controlled by a motor to ensure that the pipeline is in a horizontal state during the traction process;

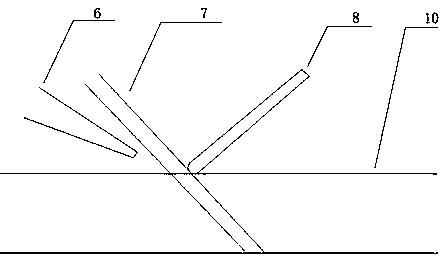

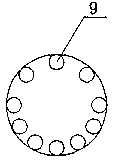

[0030] b. Preheat the inner layer core tube unwound in step a by the first preheating / winding device 11, and spray a high temperature resistant adhesive on the outer surface of the inner layer core tube by the adhesive spraying device 5, high temperature resistant The adhesive is a high-temperature-resistant adhesive multifunctional epoxy resin system; the first preheating / winding device 11 is heated by the short-wave infrared heating method of the lamp tube 9, and the distribution of the lamp tube 9 is uneven, and the lower part is used more than the upper part. The way distribu...

Embodiment 1

[0040] In this embodiment, the present invention discloses a method for preparing a fiber tape-reinforced thermoplastic resin composite pipe. The inner core tube is unwound by the unwinding device 21, first preheated by the first preheating / winding device 11, and then Adhesive spraying device 5 sprays high-temperature-resistant adhesive, and then winds the fiber tape on the inner core tube, heats the fiber tape 7 in the form of hot air blower 6 during winding, and squeezes it with pressure roller 8 after winding After the first layer is wound, it passes through the first central positioning frame 31 in turn, and the second winding device 12 performs the second layer winding, which also heats and extrudes the fibers, and the rotation direction of the second winding device 12 is the same as that of the first preheating / winding device 11 On the contrary, the speed is the same. After winding the second layer of fiber tape, it passes through the second center positioning frame 32, a...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, the difference is:

[0044] In this example, the fiber tape used is a continuous unidirectional carbon fiber tape with a width of 30 mm, a thickness of 0.15 mm, a fiber mass content of 70%, a resin matrix of PERT, a lamp tube setting temperature of 350°C, and a high-temperature binder of three Functional group epoxy resin AFG-90 / maleic anhydride system, the temperature of hot air is 400°C, the setting ratio of the tension from inside to outside of the four-layer fiber tape is 100:90:80:70, and the winding angle is 60°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com