Mixed catalyst ultrasonic atomization organic sewage purifying system under ultraviolet condition

A mixed catalyst and ultrasonic atomization technology, which is applied in oxidized water/sewage treatment, mechanical oscillation water/sewage treatment, light water/sewage treatment, etc., can solve the problems of difficult regeneration, high energy consumption and high cost of concentration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

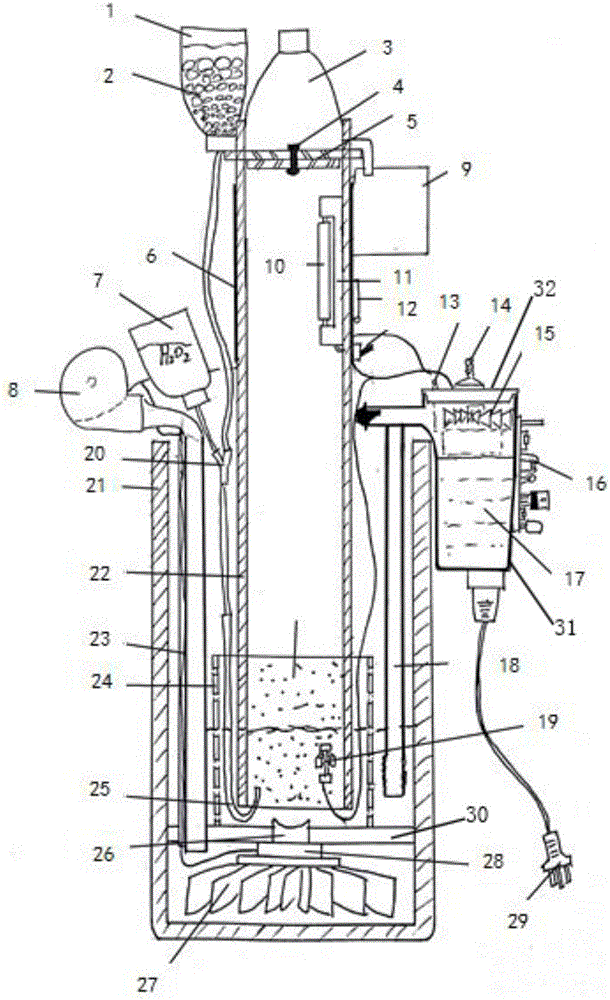

[0020] Such as figure 1 Shown is a mixed catalyst ultrasonic atomization organic sewage purification system under ultraviolet conditions, including an atomization pool 21 and an atomization tube 22, and the atomization tube 22 is arranged in the atomization pool 21; the atomization pool 21 A baffle 30 is arranged at the inner lower part, and a blower fan 27 is arranged in the space under the baffle 30. An ultrasonic device is arranged on the upper part of the blower fan 27. The ultrasonic device passes through the baffle 30, and its outlet is opposite to the bottom of the atomizing tube 22. The gap between the atomization pool 21 and the atomization pipe 22 is provided with an air inlet pipe 23, and the end of the air inlet pipe 23 is provided with a blower fan 8, and the tail passes through the baffle plate 30, and leads to the air supply fan 27; the atomization pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com