A kind of high strength and toughness casting aluminum alloy and preparation method thereof

A technology for casting aluminum alloys and aluminum alloys, which is applied in the field of aluminum alloy manufacturing, can solve problems such as poor casting performance, and achieve the effects of increased strength, broad market application value, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

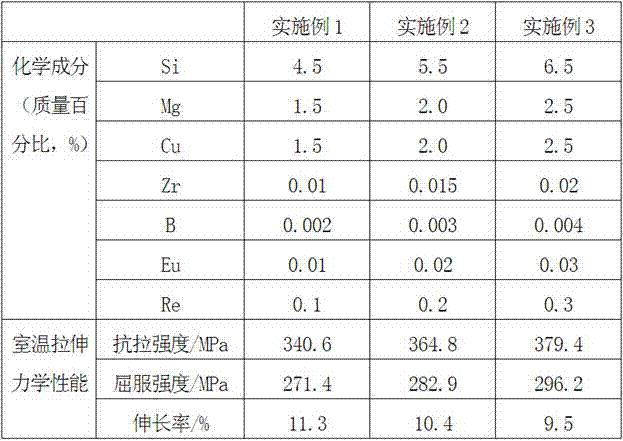

Examples

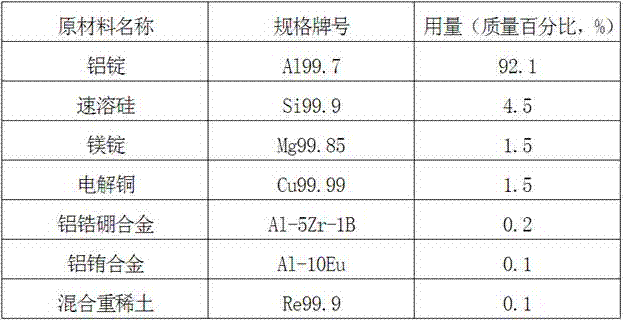

Embodiment 1

[0025] The high-strength and toughness cast aluminum alloy of the present invention contains Si 4.5%, Mg 1.5%, Cu 1.5%, Zr 0.01%, B0.002%, Eu 0.01%, Re 0.1%, and the rest is Al and unavoidable impurities, The composition and mass percentage of Re are: Tb 19%, Dy 12%, Ho 31%, Tm 13%, Yb 17%, Lu 8%. Its preparation method is as follows:

[0026] The first step: select Al-5Zr-1B alloy, Al-10Eu alloy and aluminum ingot with a purity of 99.7%, 99.9% instant silicon, 99.85% magnesium ingot, 99.99% electrolytic copper and 99.9% mixed heavy rare earth Re As raw materials, the list of ingredients is as follows:

[0027]

[0028] Step 2: Heat and melt the aluminum ingot at 770°C, add instant silicon, magnesium ingot and electrolytic copper, stir and melt to form aluminum alloy liquid;

[0029] The third step: using hexachloroethane to refine the aluminum alloy liquid, after removing slag, add Al-5Zr-1B alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the composi...

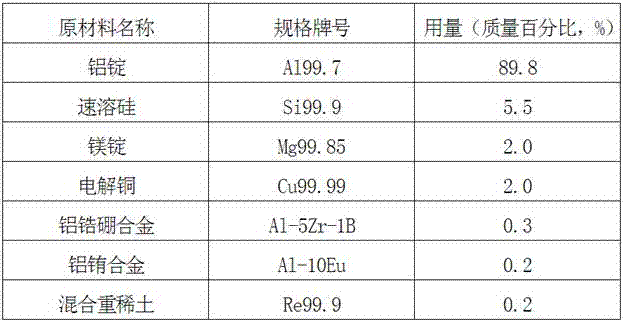

Embodiment 2

[0034] The high-strength and tough cast aluminum alloy of the present invention contains Si 5.5%, Mg 2.0%, Cu 2.0%, Zr 0.015%, B0.003%, Eu 0.02%, Re 0.2%, and the rest is Al and unavoidable impurities, The composition and mass percentage of Re are: Tb 19%, Dy 12%, Ho 31%, Tm 13%, Yb 17%, Lu 8%. Its preparation method is as follows:

[0035] The first step: select Al-5Zr-1B alloy, Al-10Eu alloy and aluminum ingot with a purity of 99.7%, 99.9% instant silicon, 99.85% magnesium ingot, 99.99% electrolytic copper and 99.9% mixed heavy rare earth Re As raw materials, the list of ingredients is as follows:

[0036]

[0037] Step 2: Heat and melt the aluminum ingot at 780°C, add instant silicon, magnesium ingot and electrolytic copper, stir and melt to form aluminum alloy liquid;

[0038] The third step: using hexachloroethane to refine the aluminum alloy liquid, after removing slag, add Al-5Zr-1B alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the compositio...

Embodiment 3

[0043] The high-strength and tough cast aluminum alloy of the present invention contains Si 6.5%, Mg 2.5%, Cu 2.5%, Zr 0.02%, B0.004%, Eu 0.03%, Re 0.03%, and the rest is Al and unavoidable impurities, The composition and mass percentage of Re are: Tb 19%, Dy 12%, Ho 31%, Tm 13%, Yb 17%, Lu 8%. Its preparation method is as follows:

[0044] The first step: select Al-5Zr-1B alloy, Al-10Eu alloy and aluminum ingot with a purity of 99.7%, 99.9% instant silicon, 99.85% magnesium ingot, 99.99% electrolytic copper and 99.9% mixed heavy rare earth Re As raw materials, the list of ingredients is as follows:

[0045]

[0046] Step 2: Heat and melt the aluminum ingot at 790°C, add instant silicon, magnesium ingot and electrolytic copper, stir and melt to form aluminum alloy liquid;

[0047] The third step: using hexachloroethane to refine the aluminum alloy liquid, after removing slag, add Al-5Zr-1B alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com