Active powder concrete noise barrier

A technology of active powder and concrete, applied in construction, noise absorption devices, etc., can solve problems such as single function, no ecological protection, general sound insulation effect, etc., to reduce the cross-sectional size, realize multi-functionality, and diversify functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

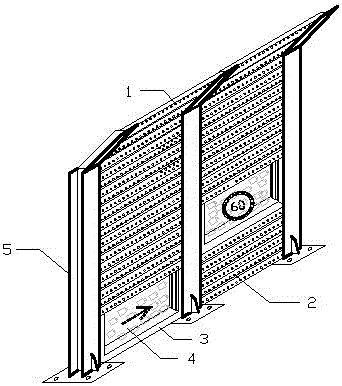

[0032] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

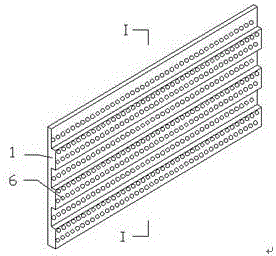

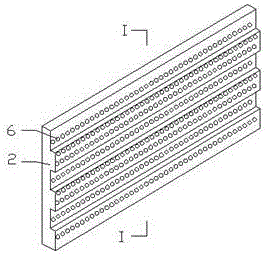

[0033] Such as figure 1 As shown, an active powder concrete sound barrier includes a thin sound-absorbing board 1 , a composite sound-absorbing board 2 , a tank body 3 , a transparent resin board 4 , and a column 5 . The thin sound-absorbing panel 1 is a single-wall thin plate with corrugations and silencing holes 6, and the composite sound-absorbing panel 2 is a composite panel with corrugations, silencing holes 6 and sound-absorbing materials. The inner wall of the tank body 3 is provided with double-layer card slots 8. The transparent resin board 4 is embedded in the card slot 8, and is arranged alternately between the columns 5. The columns 5 are cylinders with grooves on both sides, and the upper part is bent.

[0034] Such as figure 1 As shown, the thin sound-absorbing panel 1, the composite sound-absorbing panel 2, the tank body 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com