Grouting device and method for prefabricated concrete pile hole

A technology of prefabricated concrete and grouting device, which is applied in construction, infrastructure engineering, etc., can solve the problems of slow construction progress, impact on the environment, waste of cement slurry, etc., and achieve the effects of fast completion, reduced consumption, and fast and convenient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

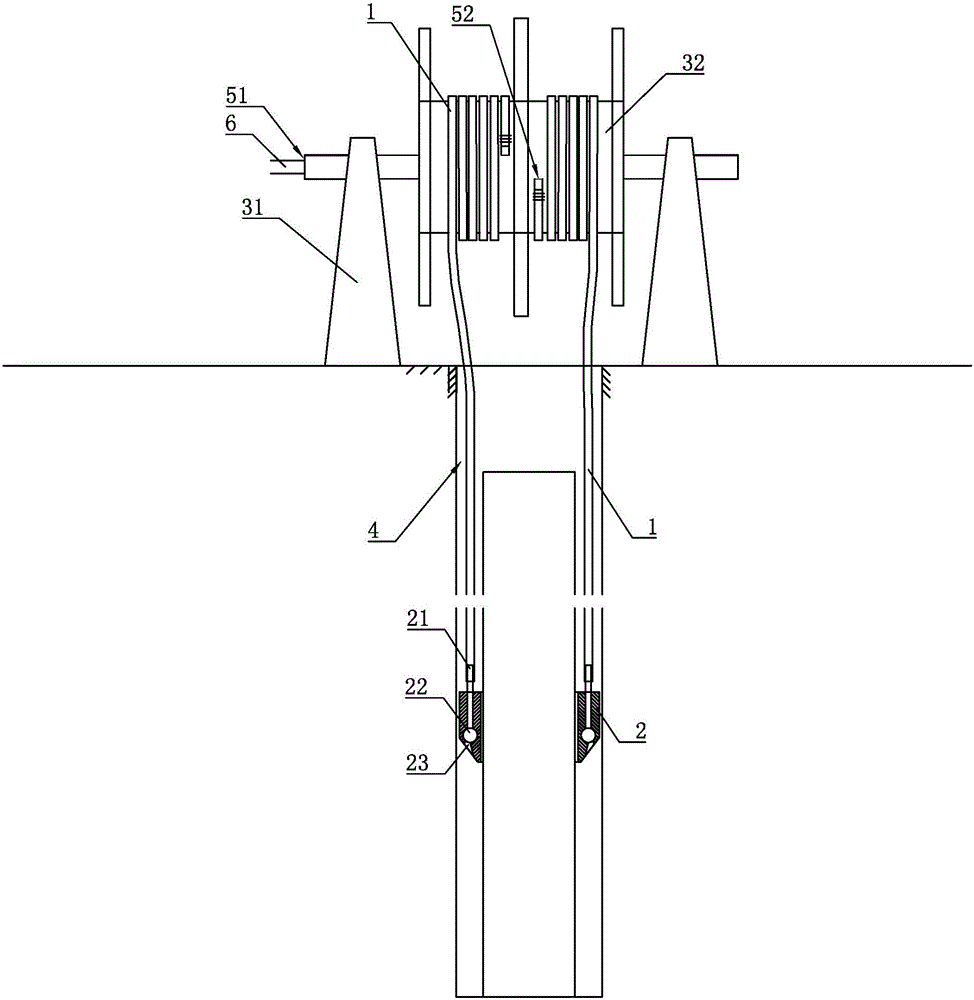

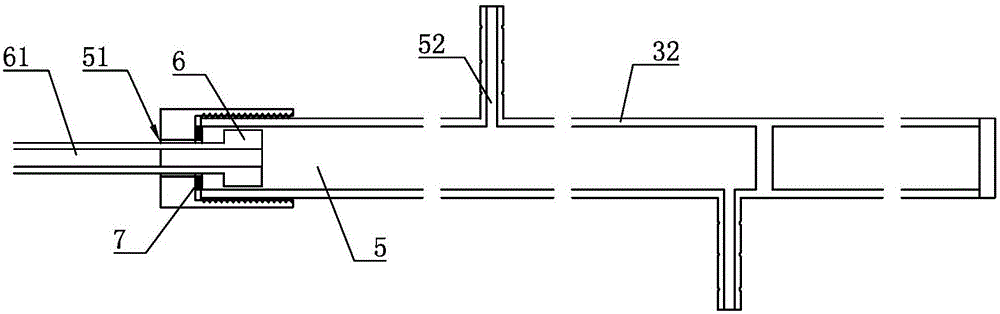

[0026] Embodiment 1: A grouting device for prefabricated concrete pile holes, including two grouting hoses 1, a hose retractable device, a high-pressure grouting device and an annular grouting head 2, and the hose retractable device includes a reel rotating The support 31 and the hose reel 32, the reel rotating support 31 is used to set up above the pile hole 4 that needs grouting, the hose reel 32 is rotatably arranged on the reel rotating support 31, the hose reel 32 The grouting inlet 51 and the grouting outlet 52 corresponding to the quantity of the grouting hose 1 are arranged on the top, the grouting inlet 51 is located at one end of the hose reel 32, and the grouting chamber 5 is arranged in the hose reel 32, and the grouting chamber 5 is stored therein. The grout chamber 5 communicates with the outside through the grouting inlet 51 and the grouting outlet 52. The high-pressure grouting device is provided with a piston-type grouting head 6, and the interior of the piston...

Embodiment 2

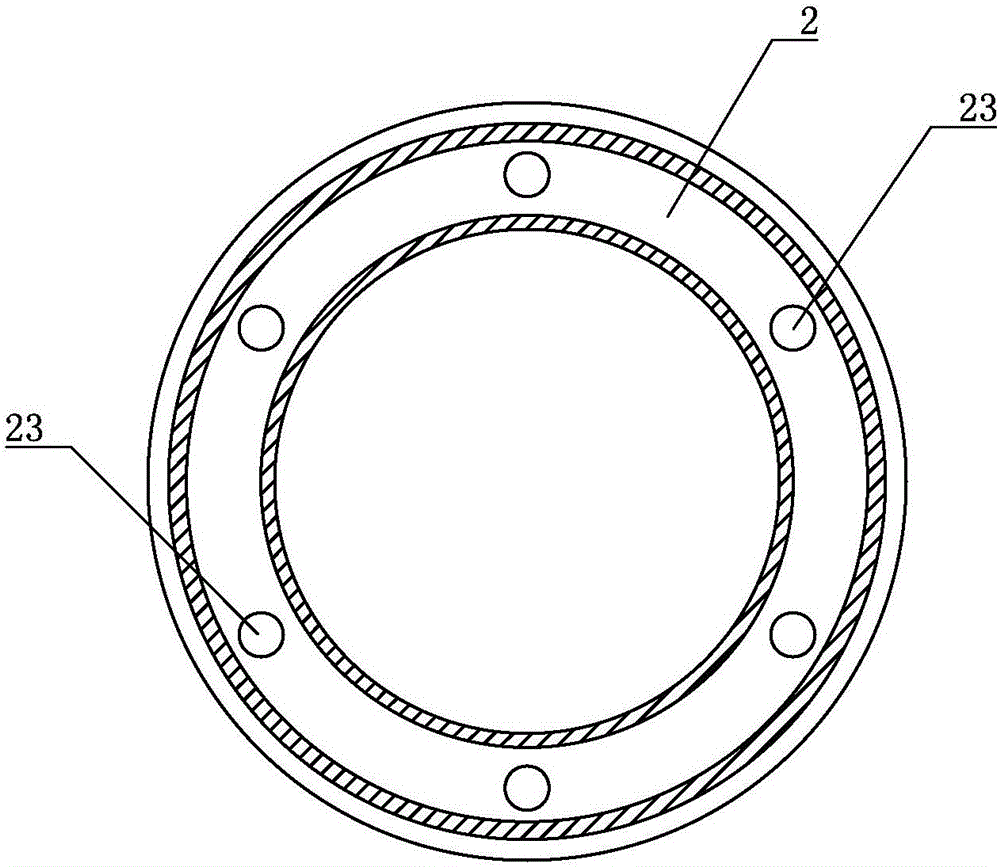

[0027] Embodiment 2: The remaining parts are the same as Embodiment 1, the difference is that a plurality of bottom grout outlets 23 are evenly distributed in the lower side of the annular grouting head 2 in a ring shape.

Embodiment 3

[0028] Embodiment 3: The remaining parts are the same as Embodiment 1, the difference is that there are four grouting hoses 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com