Cement reinforced gypsum board

A technology of gypsum board and paper-faced gypsum board, applied in construction, building structure, covering/lining, etc., can solve the problems of easy deformation and unsatisfactory effect, so as to improve strength, avoid flexural strength and improve surface hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

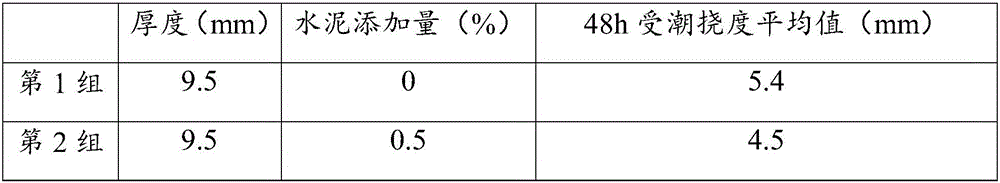

[0024] The results of recent tests on the moisture deflection of cement gypsum boards are shown in Table 1 (the conventional dosage of starch is 25g / m 2 ; The amount of starch in the gypsum board after adding cement is 33g / m 2 ; the water paste ratio is 70% and 73% respectively; the drying temperature is respectively 130°C at the outlet of the first zone and 90°C at the outlet of the second zone; 135°C at the outlet of the first zone and 88°C at the outlet of the second zone):

[0025]

[0026] Experimental conditions: 32°C, 90% humidity, constant temperature and humidity for 48 hours, gypsum boards placed horizontally. The tested gypsum boards were all experimentally produced in the production line. The only variable in each group was the amount of cement added, and the other added amounts remained unchanged. The main line speed was 48m / min (the same below).

Embodiment 2

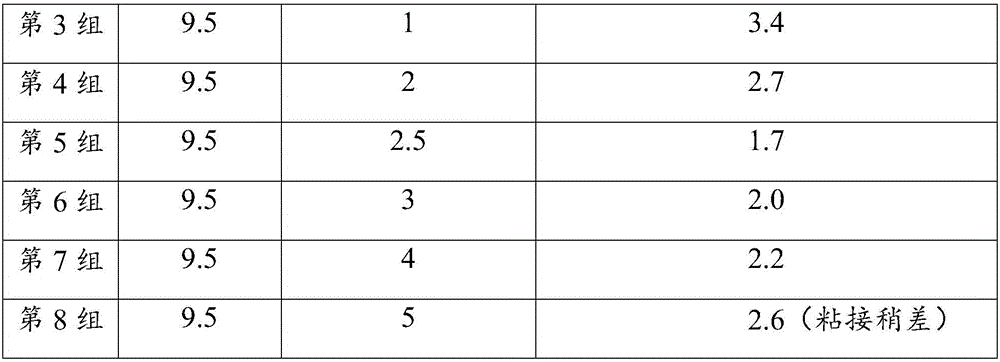

[0028] The test results of the moisture deflection performance of 9.5mm thick gypsum boards with different cement additions are shown in Table 2: (The conventional dosage of starch is 25g / m 2 ; The amount of starch in the gypsum board after adding cement is 33g / m 2 ; the water paste ratio is 70% and 73% respectively; the drying temperature is respectively 130°C at the outlet of the first zone and 90°C at the outlet of the second zone; 135°C at the outlet of the first zone and 88°C at the outlet of the second zone):

[0029]

[0030]

[0031] Experimental conditions: 32°C, 90% humidity, constant temperature and humidity for 48 hours, gypsum boards placed horizontally.

Embodiment 3

[0033] The test results of the moisture deflection performance of 12mm thick gypsum boards with different cement additions are shown in Table 3: (The conventional dosage of starch is 25g / m 2 ; The amount of starch in the gypsum board after adding cement is 33g / m 2 ; The water paste ratio is 70% and 73% respectively; the drying temperature is respectively 130°C at the outlet of the first zone, 90°C at the outlet of the second zone, 135°C at the outlet of the first zone, and 88°C at the outlet of the second zone):

[0034]

[0035] Experimental conditions: 32°C, 90% humidity, constant temperature and humidity for 48 hours, gypsum boards placed horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com