A Deep Well Drilling Mechanism Based on Uphole Pressure Applied Automatically Strengthening the Drill Bit

A kind of drill bit, automatic technology, applied in the direction of drill bit, drilling equipment, drill pipe, etc., can solve the problems of high cost, time cost increase, drill bit wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

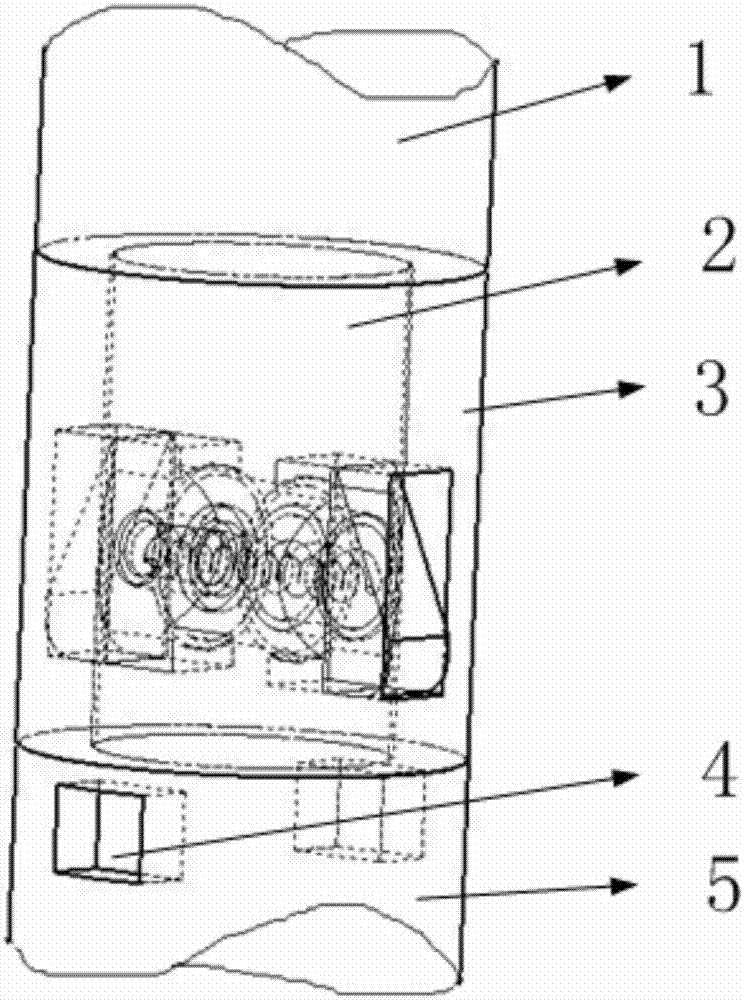

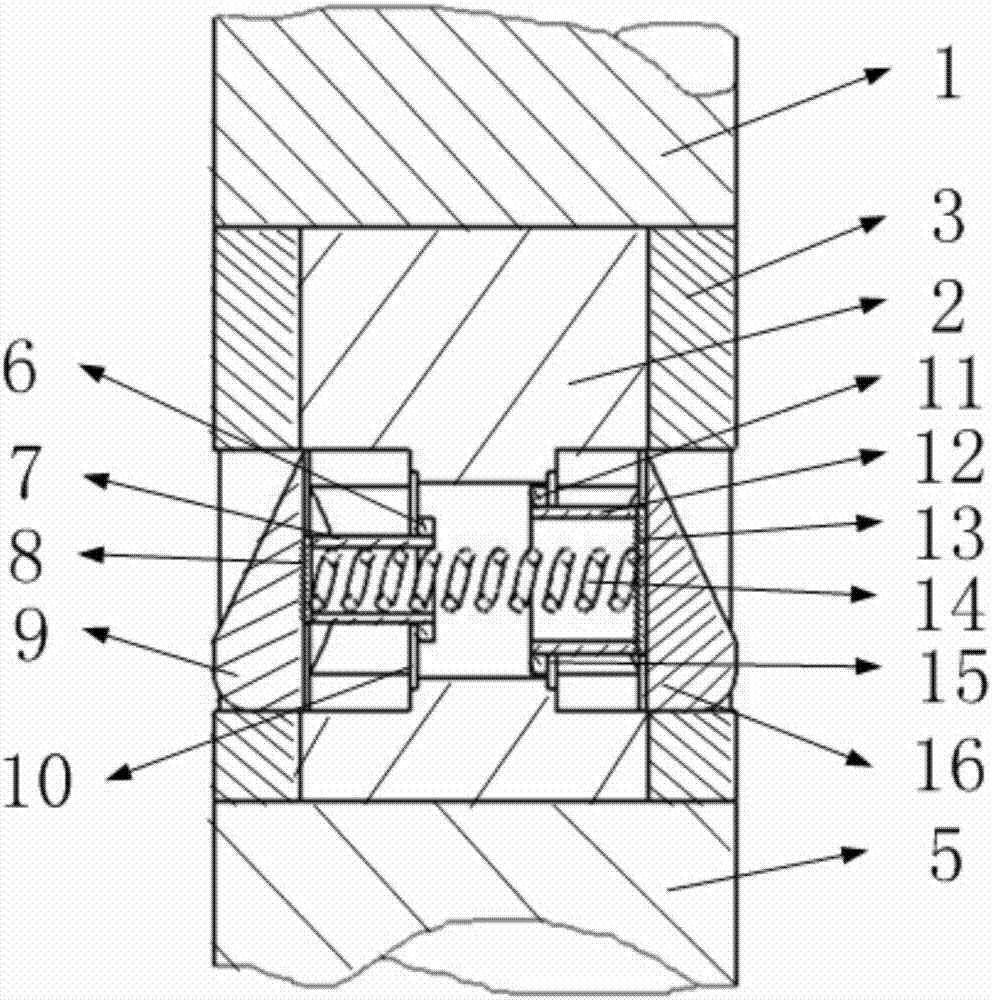

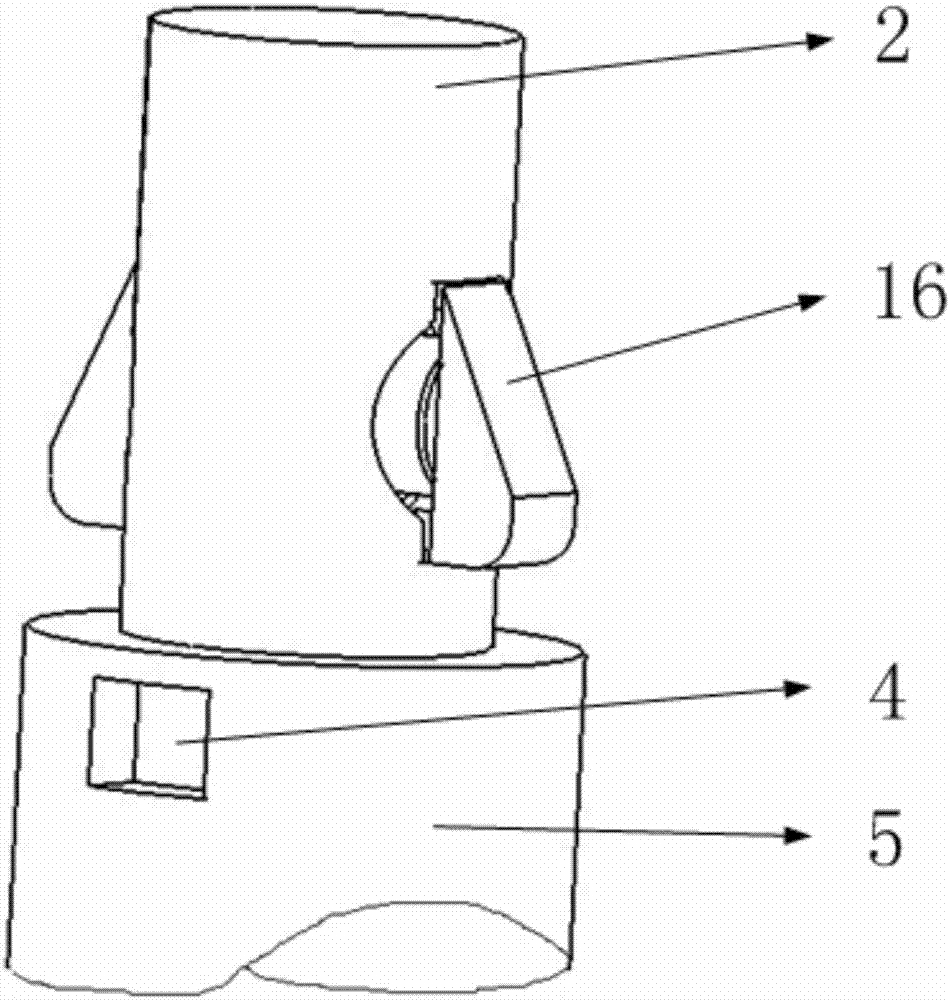

[0090] The invention includes an uphole pressure applying mechanism, a drill pipe positioning mechanism and an automatic reinforced drill bit, wherein the drill pipe positioning mechanism is installed on the drill pipe of the uphole pressure applying mechanism, and the automatic strengthening drill bit is installed at the bottom end of the drill pipe of the uphole pressure applying mechanism.

[0091] Such as Figure 11 As shown, the above-mentioned uphole pressure applying mechanism includes a drill pipe fixing mechanism chute, a first rotating shaft, a first rotating shaft support ring, a support ring support, a support ring support frame, a second gear, a first gear, a drive motor shaft, and a thread pressure application mechanism. Mechanism, driving motor, support of pressure applying mechanism, support plate of threaded pressure applying mechanism, hollow driving shaft hole, drill pipe shaft, drill pipe connection structure, drill pipe fixing mechanism, hollow driving rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com