Cantilever linkage auxiliary device and working method and application thereof

An auxiliary device and linkage technology, which is applied in the field of tunnel excavation equipment and mines, can solve the problems of poor stability of equipment mechanism, large changes of roadheaders, single function, etc., and achieve good effect, low production cost and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

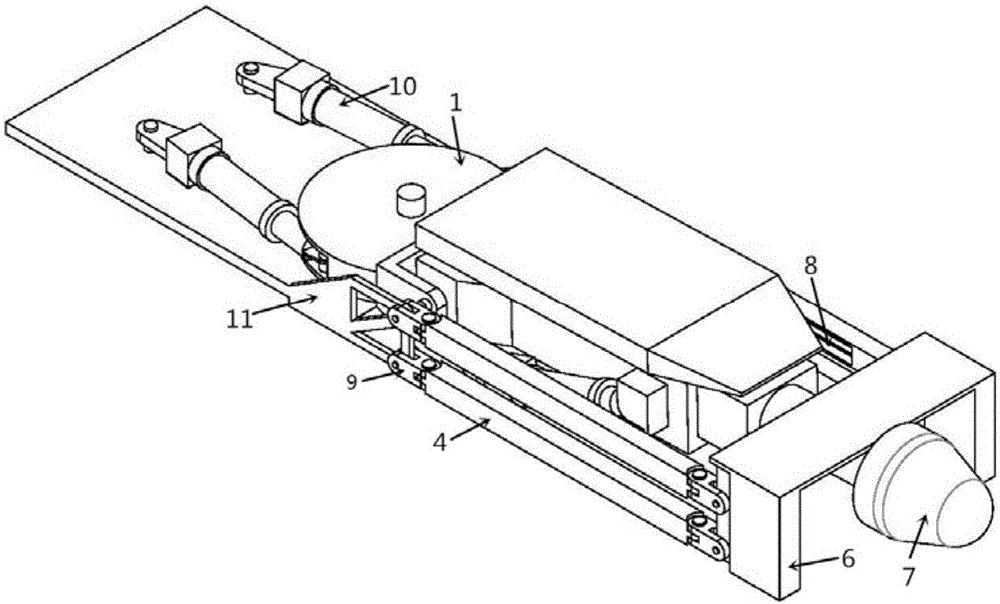

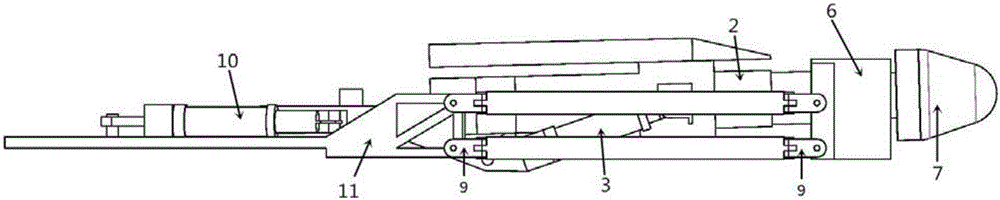

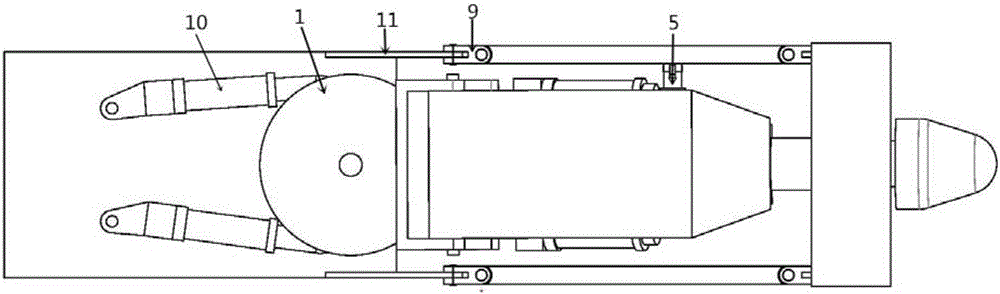

[0047] The cantilever linkage auxiliary device includes an auxiliary arm and an auxiliary platform, the auxiliary arm is arranged on both sides of the main cantilever of the roadheader, the auxiliary arm is connected with the machine frame of the roadheader, and the auxiliary platform is connected with the auxiliary arm. The auxiliary arm is used to support the auxiliary platform, and the auxiliary platform is connected with the main cantilever of the existing roadheader through the auxiliary arm, so as to facilitate the installation of different auxiliary equipment such as ultrasonic detectors and dust suppression equipment on the auxiliary platform according to the needs of different environments. Due to the limitation of the auxiliary arms on both sides, the auxiliary platform is always linked with the body of the roadheader, and various equipment can be hung on the auxiliary platform. The top plate of the auxiliary platform is not only the installation of auxiliary equipment...

Embodiment 2

[0052] A cantilever linkage auxiliary device, the structure of which is as described in Embodiment 1, the difference is that the sliding seat is provided with a sliding seat shaft hole, the sliding seat shaft hole is provided with a sliding seat shaft, and the two ends of the sliding seat shaft are provided with sliders , the slider is flexibly connected with the slide rail. Grooves are provided on the surface of the slider, and the grooves are matched and connected with the slide rails. The shaft of the slide seat is set through the shaft hole of the slide seat, and the slide block cooperates with the slide rail through the groove, so that the slide seat can move along the slide rail.

Embodiment 3

[0054] A cantilever linkage auxiliary device, the structure of which is as described in Embodiment 2, the difference is that a stop plate is provided on the base shaft between the base and the main cantilever. It is convenient for the installation and positioning of the transmission knuckle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com