High-energy pipeline impact energy absorber

A technology of high-energy pipelines and energy absorbers, which is applied in the field of vibration and shock, can solve problems such as pipeline rebound, secondary impact, and aggravate the severity of accidents, and achieve the effects of reducing production costs, high reliability, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

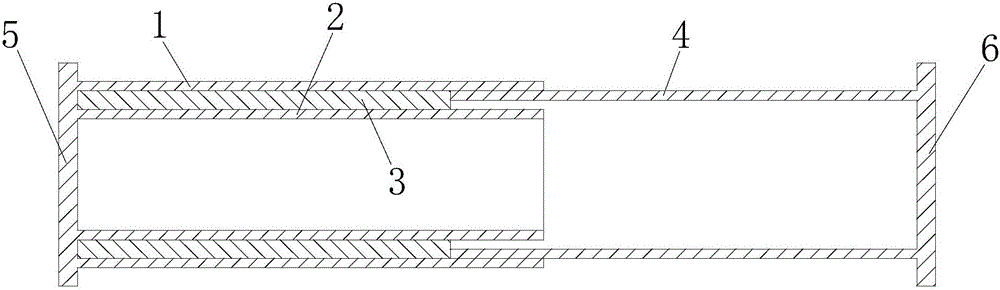

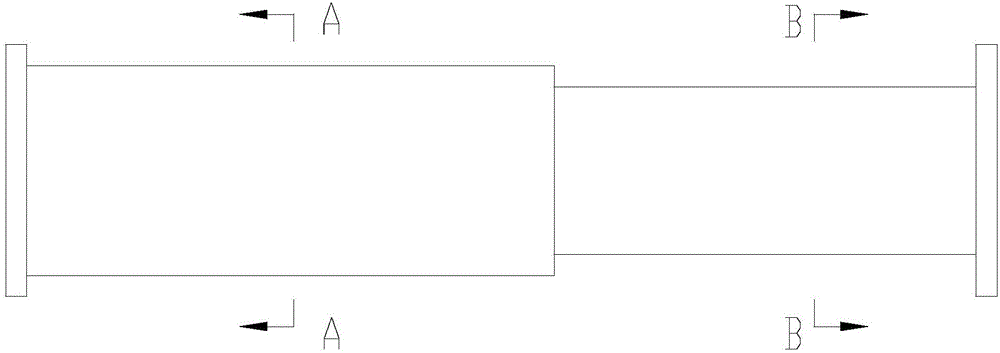

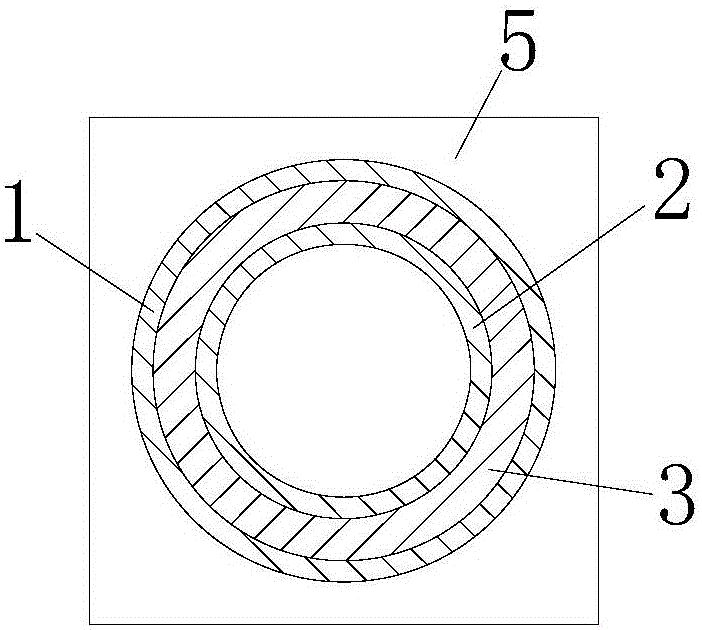

[0029] In this embodiment, the outer casing 1 and the inner casing 2 are welded on the casing end baffle 5, the outer casing 1 has an outer diameter of 100mm, an inner diameter of 90mm, and a length of 150mm; the inner casing 2 has an outer diameter of 70mm, an inner diameter of 60mm, and a length of 150mm; The gap between the outer casing 1 and the inner casing 2 is filled with the energy-dissipating lead body 3, the length of which is 100 mm; the impact tube 4 is welded on the end baffle plate 6 of the impact tube, and the length is 150 mm, and the impact tube 4 extends into the outer casing 1 and the inner sleeve The length between the tubes 2 is 50mm, and the outer tube 1, the inner tube 2, the tube end baffle 5, the impact tube 4, and the impact tube end baffle 6 are all made of Q235 steel.

[0030] In this embodiment, in the initial state, the impact tube 4 is just in contact with the energy-dissipating lead body 3, and there is no extrusion force; when pressure is slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com