Thermostatic expansion valve

A thermal expansion valve and thermal technology, applied in the field of thermal expansion valves and various thermal expansion valves, can solve problems such as valve port leakage, dirty air-conditioning system, system garbage blockage, etc., to achieve good sealing performance, smooth flow change, and valve The effect of small mouth leakage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

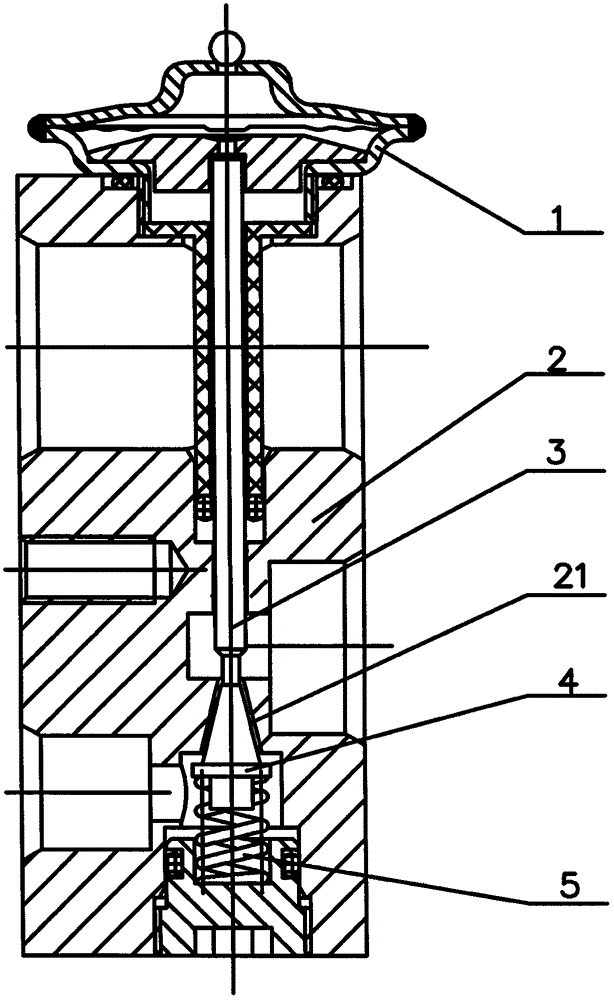

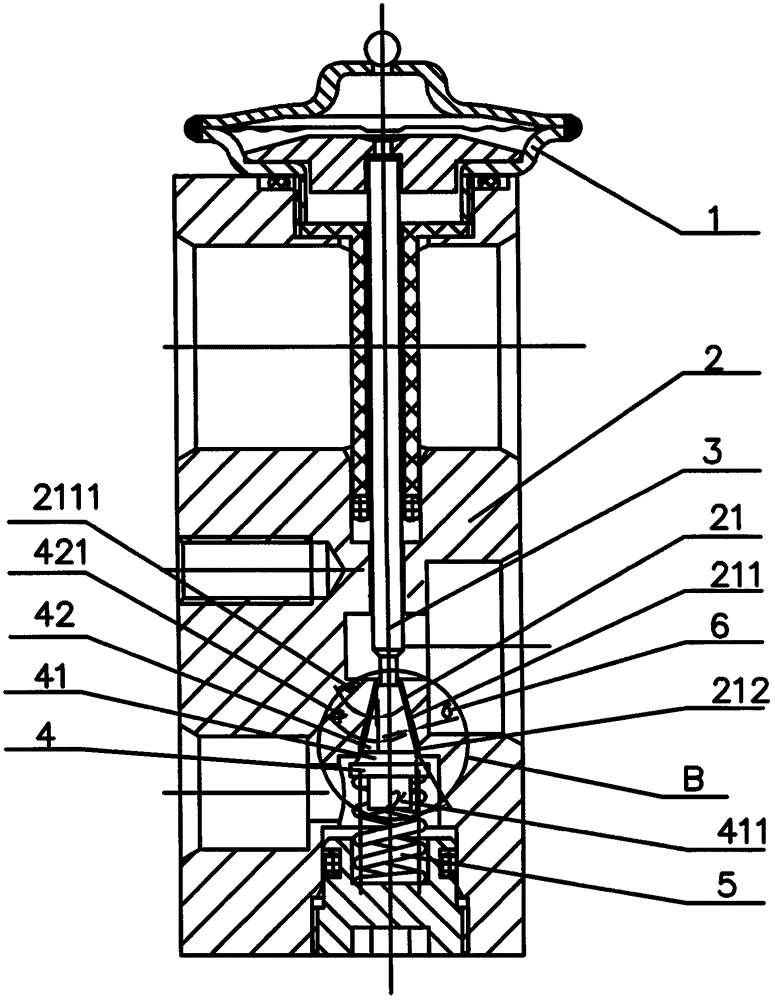

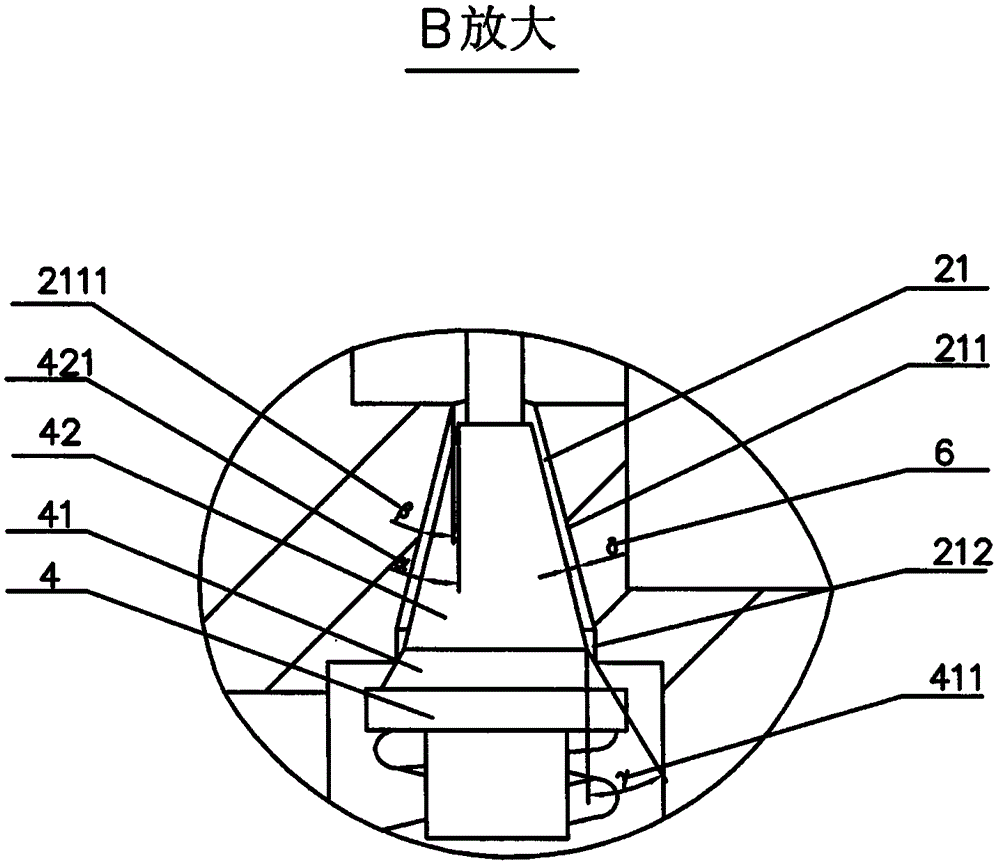

[0017] Such as figure 2 , image 3 As shown, the present invention is mainly composed of a thermal head 1, a valve body 2, a valve stem 3, a valve core 4, an adjustment spring 5, and the like. The valve seat hole 21 is composed of a valve seat conical hole 211 and a valve seat cylindrical hole 212; The cone angle 411 is greater than the conical cone angle 421 on the valve core, the conical cone angle 421 on the valve core is equal to the cone angle 2111 of the conical hole on the valve core, and the conical 42 on the valve core and the conical hole 211 on the valve seat have a minimum fixed clearance of 6 .

[0018] It works as follows:

[0019] When the air conditioning system is not working, the thermal expansion valve is in the closed state, and the conical shape 41 under the valve core is in a line-sealed state with the cylindrical hole 212 of the valve seat. The sealing performance is good, and the leakage value of the valve port of the thermal expansion valve is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com