Intelligent bearing based on Hall displacement sensor

A displacement sensor, Hall-type technology, applied in the field of bearings, can solve problems such as affecting the accuracy of bearing signals, and achieve the effects of good accuracy, engineering promotion, and easy engineering promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

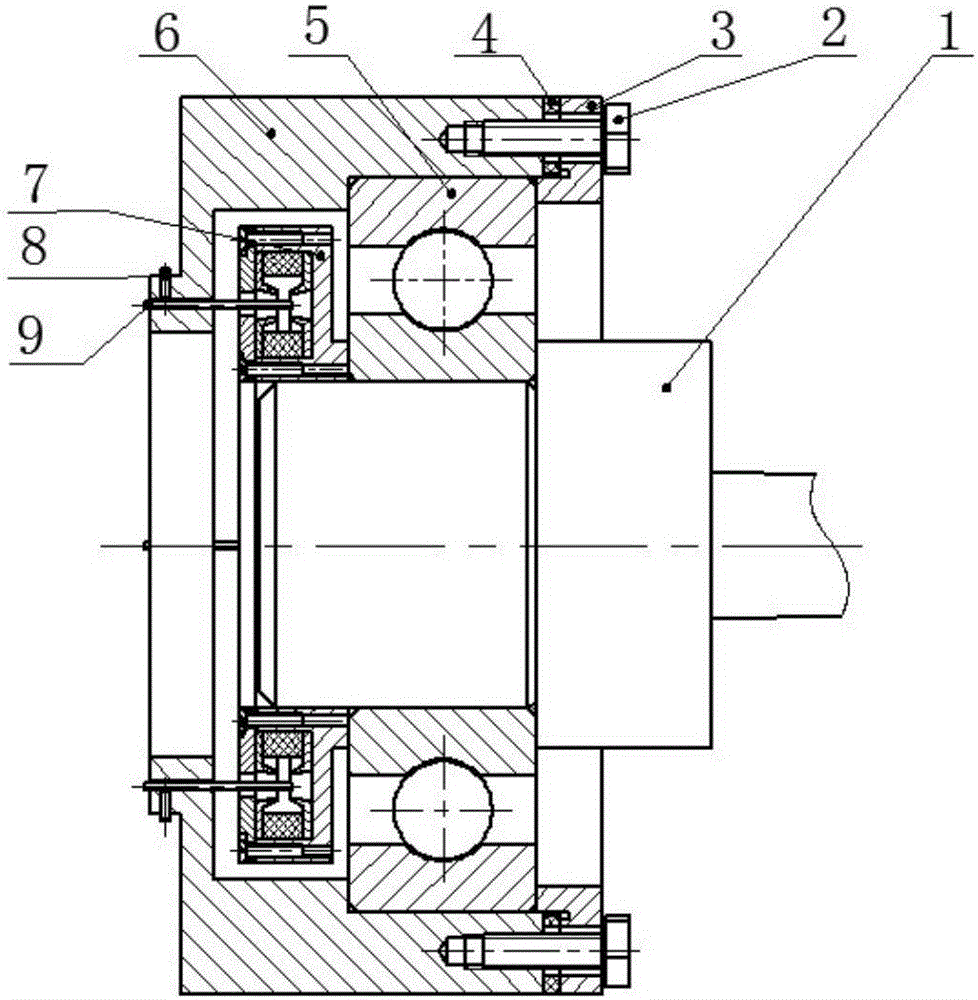

[0024] like figure 1 As shown, the smart bearing based on the Hall-type displacement sensor is mainly composed of a mandrel 1, a bearing end cover 3, a rolling bearing 5, a bearing seat 6, a side-mounted measuring ring 7 and four Hall probes 9.

[0025] The side-mounted measuring ring 7, the rolling bearing 5 and the bearing end cover 3 are arranged coaxially on the bearing seat 6 from the inside to the outside in sequence; the bearing end cover 3 is fixed on the bearing seat 6 by bolts 2, in order to adjust its The size, the gasket 4 is set between the bearing seat 6 and the end cover 3 of the bearing.

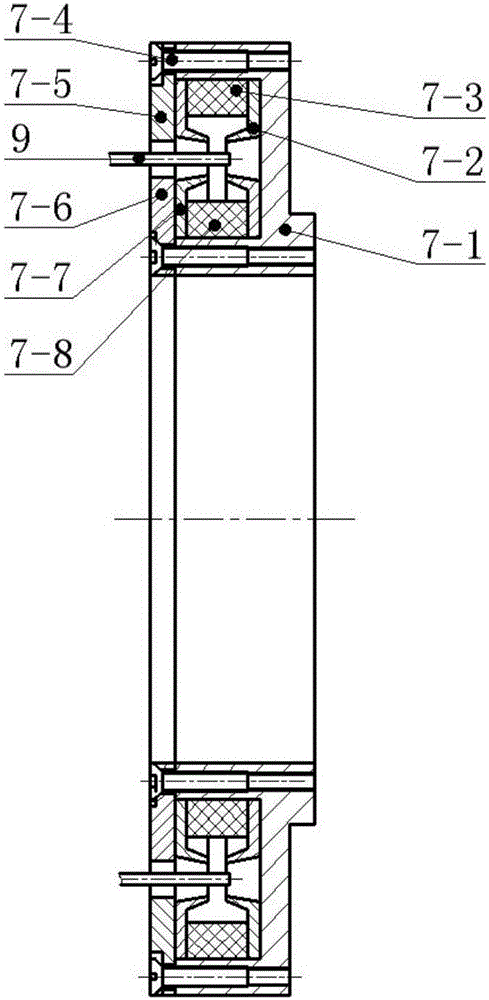

[0026] The four Hall probes 9 are evenly distributed on the ring of the side-mounted measuring collar 7, and are located in the middle of the ring. The rolling bearing 5 and the side-mounted measuring ring 7 are arranged on the outer ring of the mandrel 1, and both of them are evenly fitted with the mandrel 1 for interference or transition fit, and connection methods such as...

Embodiment approach 2

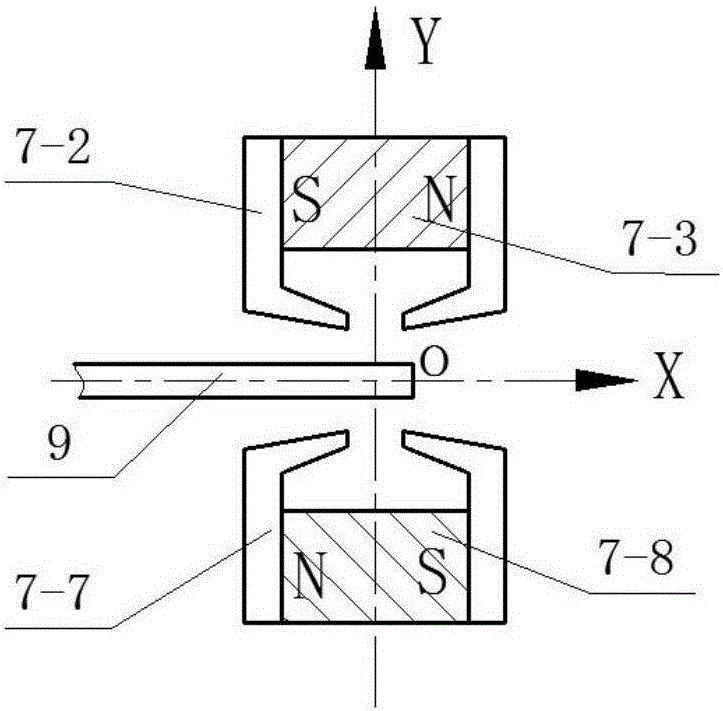

[0030] This embodiment is basically the same as Embodiment 1, the only difference lies in the arrangement of the permanent magnets in the side-mounted measuring ferrule 7 that specifically generate a uniform gradient magnetic field. This embodiment adopts the opposite structure, such as Figure 4 As shown, the polarities of the large magnetic ring 7-3 and the small magnetic ring 7-8 are oppositely placed, and the Hall sensor 9 is placed in the center of the gap generated by the large magnetic ring 7-3 and the small magnetic ring 7-8. This structure will generate a uniform gradient magnetic field in the Y-axis direction, and its magnetic induction intensity is 0 at the center position, and increases linearly along the positive and negative directions of the Y-axis, and the direction is opposite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com