Orthogonal glued wood board reinforced by nanocomposite and manufacture method thereof

A technology of nano-composite material and manufacturing method, which is applied in the field of orthogonal glulam boards, can solve the problems of tearing damage of glue layer, low tensile strength of rolling shear strength and horizontal grain, and rolling shear damage, etc., so as to improve the rolling shear strength, The effect of improving bending and shearing properties and improving the tensile strength of transverse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

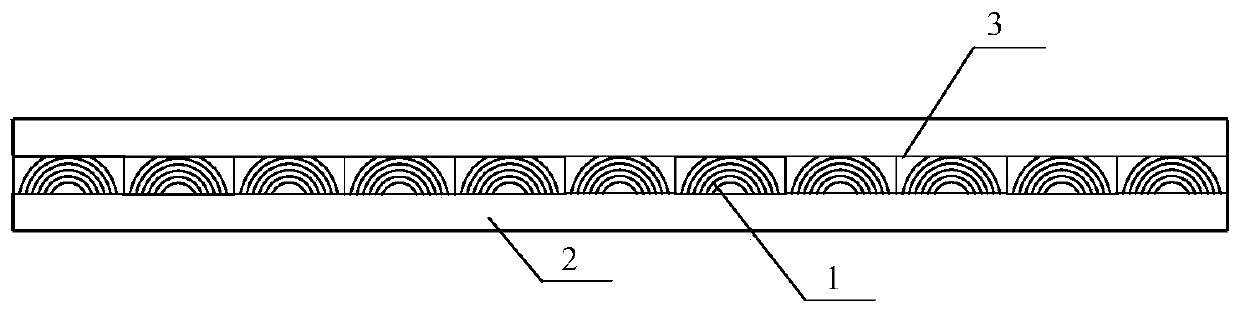

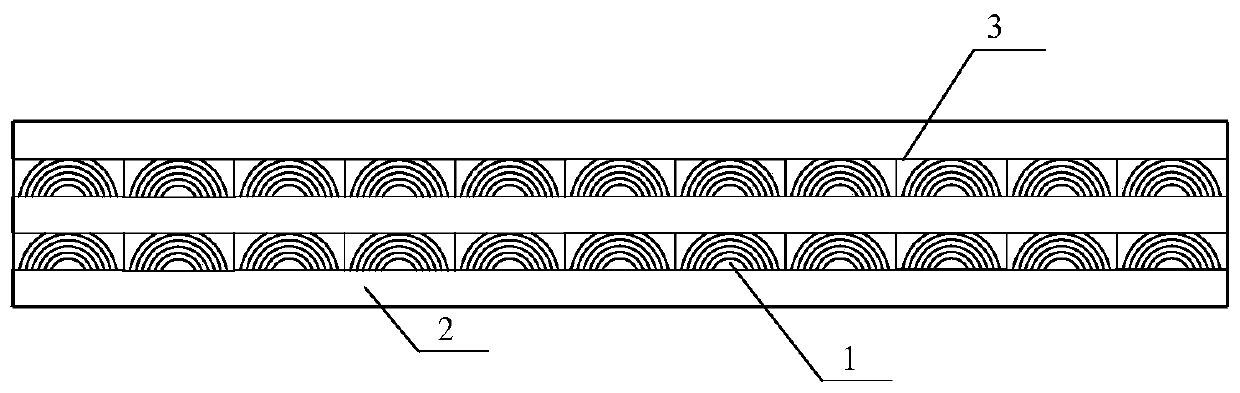

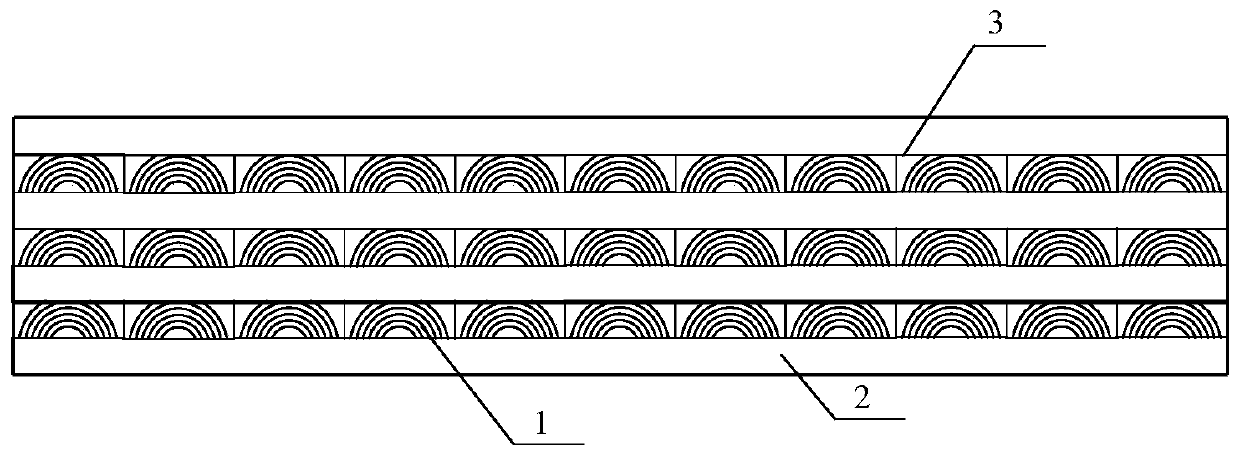

[0029] see Figure 1-Figure 6 , a cross-laminated wood board strengthened by a nanocomposite material, comprising a first board 1, a second board 2, and a structural adhesive layer 3; the first board 1 is soaked in a nanocomposite solution, and ultrasonic waves are used to make The board after the composite material is evenly dispersed into the microstructure of the wood; the first board 1 and the second board 2 are stacked alternately and glued by the structural adhesive layer 3, and the top layer and the bottom layer are the second board 2; the first board 1 and the second board The wood grain direction of plate 2 is perpendicular to each other, combining figure 1 with Figure 4 As can be seen.

[0030] In this embodiment, the second board 2 in the cross-laminated wood board has one more layer than the first board 1, and the total number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com