Method for evaluating snow and ice melting capacity of anti-freezing asphalt mixture

A technology of asphalt mixture and evaluation method, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of complex preparation process and large shear force deviation, and achieve simple operation steps, accurate bond strength, and accurate data reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

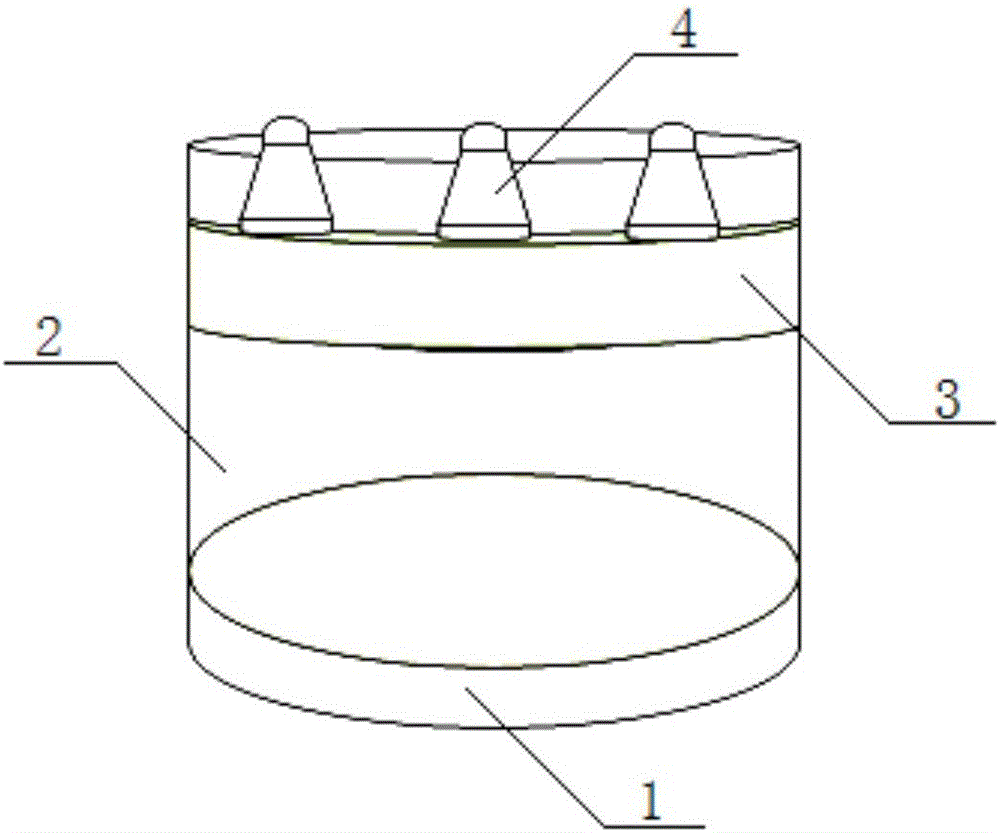

[0024] like figure 1 and figure 2 The schematic diagram of the ice and snow melting ability evaluation test piece of the antifreeze asphalt mixture shown, the specific evaluation steps are as follows:

[0025] Step 1: Form a set of (3) cylindrical antifreeze asphalt mixture specimens 2 with a height of 63.5mm and a diameter of 101.6mm by Marshall's method. Apply a layer of paraffin evenly;

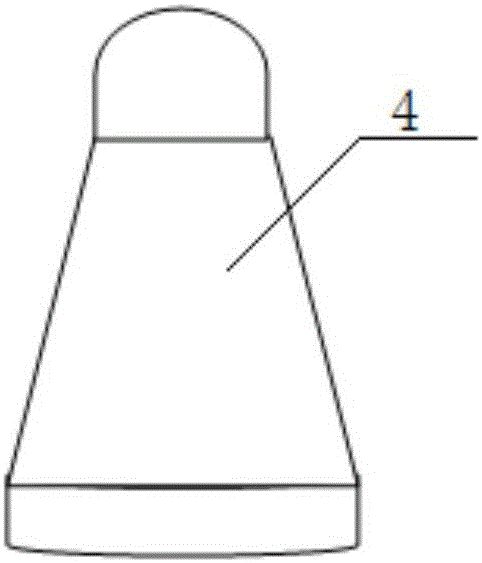

[0026] Step 2: Place the test piece 2 in step 1 under the environmental condition of -5°C, spray 4mm thick pre-prepared water at 0°C on the surface of the test piece 2, and put the drawing head 4 on the surface of the test piece 2 at the same time, Freeze together with water, place 3 pulling heads 4 on the surface of each Marshall test piece 2;

[0027] Step 3: Continue to place the specimen 2 in step 2 for a freezing test for 24 hours at -5°C, and then conduct a small pull-out test at -5°C using an adhesion puller with a loading rate of 0.02MPa / s, record the pull-out strength when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com