Gas concentration calibration method for gas sensor

A technology of gas sensor and calibration method, which is applied in the field of sensors, can solve problems such as errors, and achieve the effect of improving sensitivity and obvious linear relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

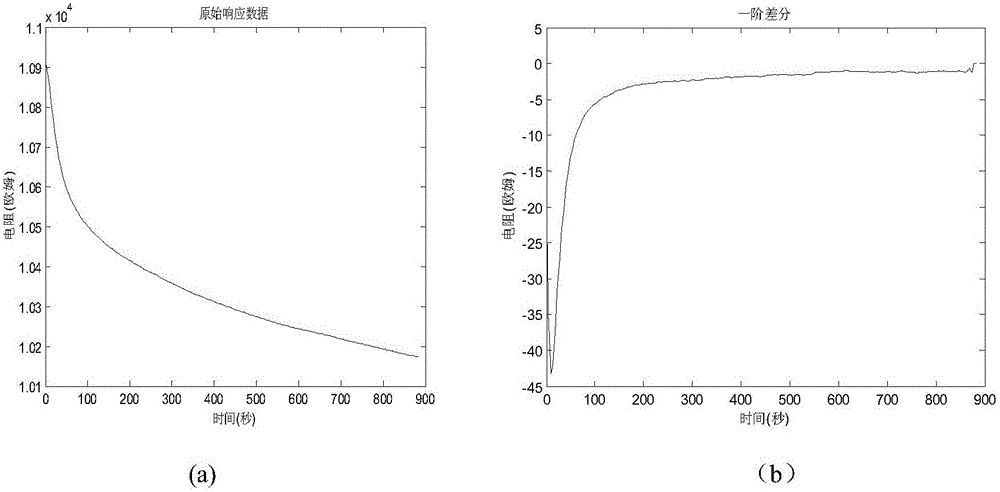

[0032] Step 1: Test ammonia (NH 3 ) data, with 500ppm dry air as the base gas; 20ppm ammonia gas (NH 3 ) as the detection gas, the collection time interval is 4 seconds, and a set of response data [R 1 , R 2 ,...,R n ], the data here is the test resistance value after passing through the ammonia gas;

[0033] Step 2: For the data obtained in step 1 [y 1 ,y 2 ,...,y n ]=[R 1 , R 2 ,...,R n ] for the following processing:

[0034] (1) Find the first-order difference: Δy i =y i+1 -y i ;

[0035] (2) Find the extreme value of the first-order difference;

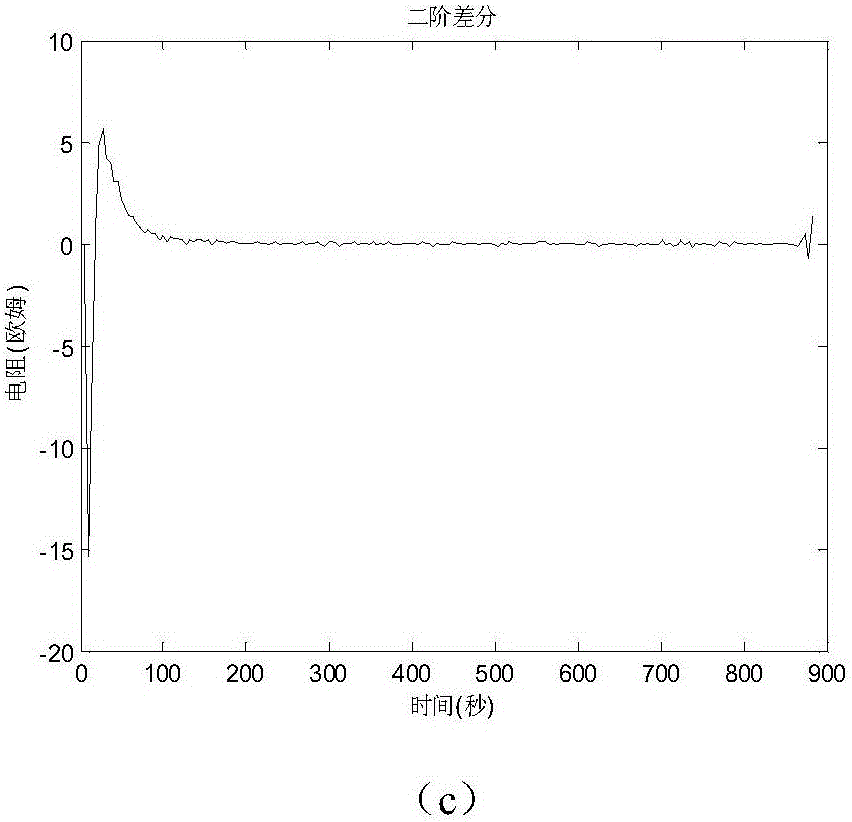

[0036] (3) Find the second order difference: Δ 2 the y i =Δy i+1 -Δy i =(y i+2 -yi+1)-(y i+1 -y i )=y i+2 -2y i+1 +y i ;

[0037] (4) Find the two extreme values of the second order difference;

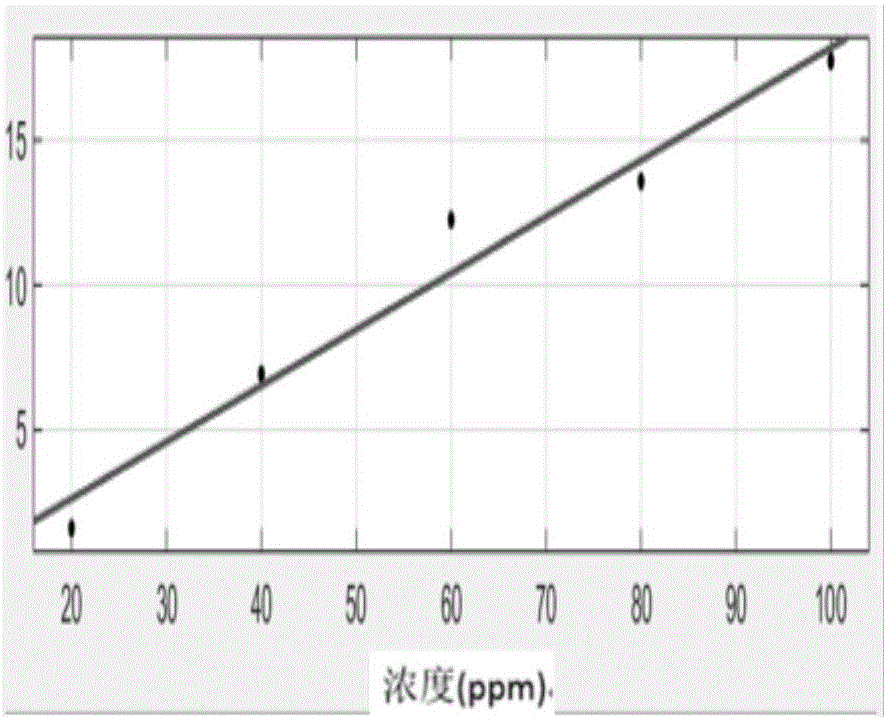

[0038] Step 3: Change the concentration of the incoming detection gas to 40ppm, 60ppm, 80ppm, and 100ppm in sequence, and repeat steps 1 and 2 to obtain another four sets of data. The minimum value of the seco...

Embodiment 2

[0041] Step 1: Test nitrogen dioxide (NO 2) data, with 500ppm dry nitrogen as the base gas; 20ppm nitrogen dioxide (NO 2 ) as the detection gas, the collection time interval is 1 second, and a set of response data [R 1 , R 2 ,...,R n ], where the data is the test resistance value after nitrogen dioxide is introduced;

[0042] Step 2: For the data obtained in step 1 [y 1 ,y 2 ,...,y n ]=[R 1 , R 2 ,...,R n ] for the following processing:

[0043] (1) Find the first-order difference: Δy i =y i+1 -y i ;

[0044] (2) Find the extreme value of the first-order difference;

[0045] (3) Find the second order difference: Δ 2 the y i =Δy i+1 -Δy i =(y i+2 -yi+1)-(yi+1-y i )=y i+2 -2y i+1 +y i ;

[0046] (4) Find the two extreme values of the second order difference;

[0047] Step 3: Change the concentration of the incoming detection gas to 40ppm, 60ppm, 80ppm, and 100ppm in sequence, and repeat steps 1 and 2 to obtain another four sets of data. The minimum val...

Embodiment 3

[0049] Step 1: Test nitrogen dioxide (NO 2 ) data, with 500ppm dry nitrogen as the base gas; 20ppm nitrogen dioxide (NO 2 ) as the detection gas, the collection time interval is 2 seconds, and a set of response data [R 1 , R 2 ,...,R n ], where the data is the test resistance value after nitrogen dioxide is introduced;

[0050] Step 2: For the data obtained in step 1 [y 1 ,y 2 ,...,y n ]=[R 1 , R 2 ,...,R n ] for the following processing:

[0051] (1) Find the first-order difference: Δy i =yi+1-y i ;

[0052] (2) Find the extreme value of the first-order difference;

[0053] (3) Find the second order difference: Δ 2 the y i =Δy i+1 -Δy i =(y i+2 -yi+1)-(y i+1 -y i )=y i+2 -2y i+1 +y i ;

[0054] (4) Find the two extreme values of the second order difference;

[0055] Step 3: Change the concentration of the incoming detection gas to 40ppm, 60ppm, 80ppm, and 100ppm in sequence, and repeat steps 1 and 2 to obtain another four sets of data. The minimum v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com