Dry-type transformer

A dry-type transformer and temperature controller technology, applied in the field of transformers, can solve problems such as combustion and explosion, and achieve the effects of strong short-circuit resistance, strong heat resistance, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

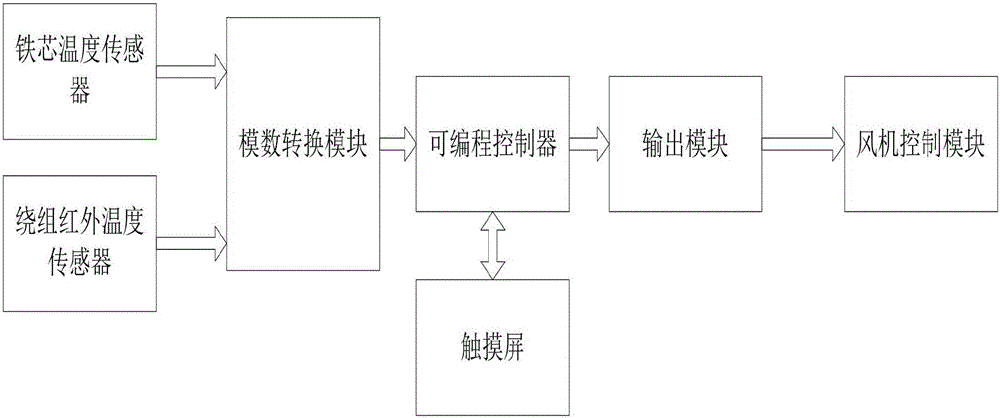

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

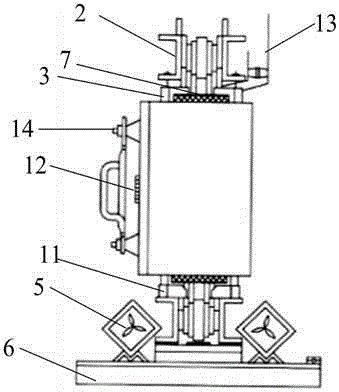

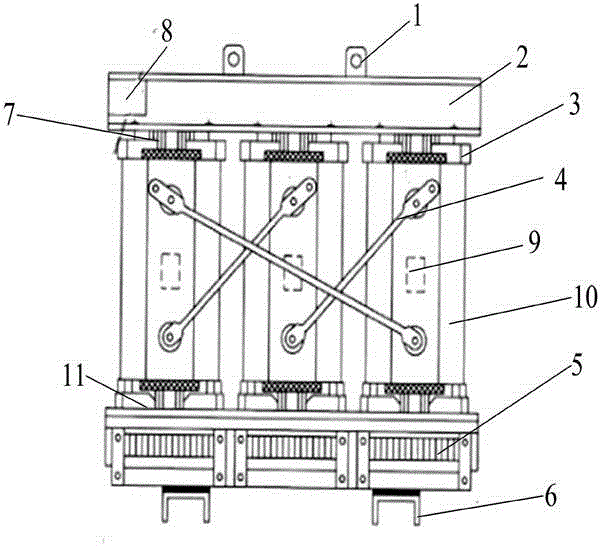

[0019] Such as figure 1 and figure 2 As shown, the dry-type transformer of the present invention includes a suspension ring 1, a clamp 2, an upper pad 3, a high-voltage connecting rod 4, a fan 5, a pad 6, a cooling plate 7, a temperature controller 8, a high-voltage connecting piece 9, an insulating shell 10, The lower block 11, the high-voltage tap 12, the low-voltage outlet copper plate 13, the high-voltage terminal 14, the lifting ring 1 is located above the clamp 2, the upper block 3 is located above the insulating shell 10, the high-voltage connecting rod 4 is connected to the cooling fin 7, and the fan 5 is located Above the pad 6, the cooling fin 7 is located inside the insulating shell 10, the thermostat 8 is connected to the clip 2, the high-voltage connecting piece 9 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com