Battery cooling device

A cooling device and battery technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as low heat storage speed, unstable performance, and reduced overall functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The purpose of the present invention is to provide a battery cooling device, which can quickly and stably cool the battery, and ensure high efficiency and safety of cooling.

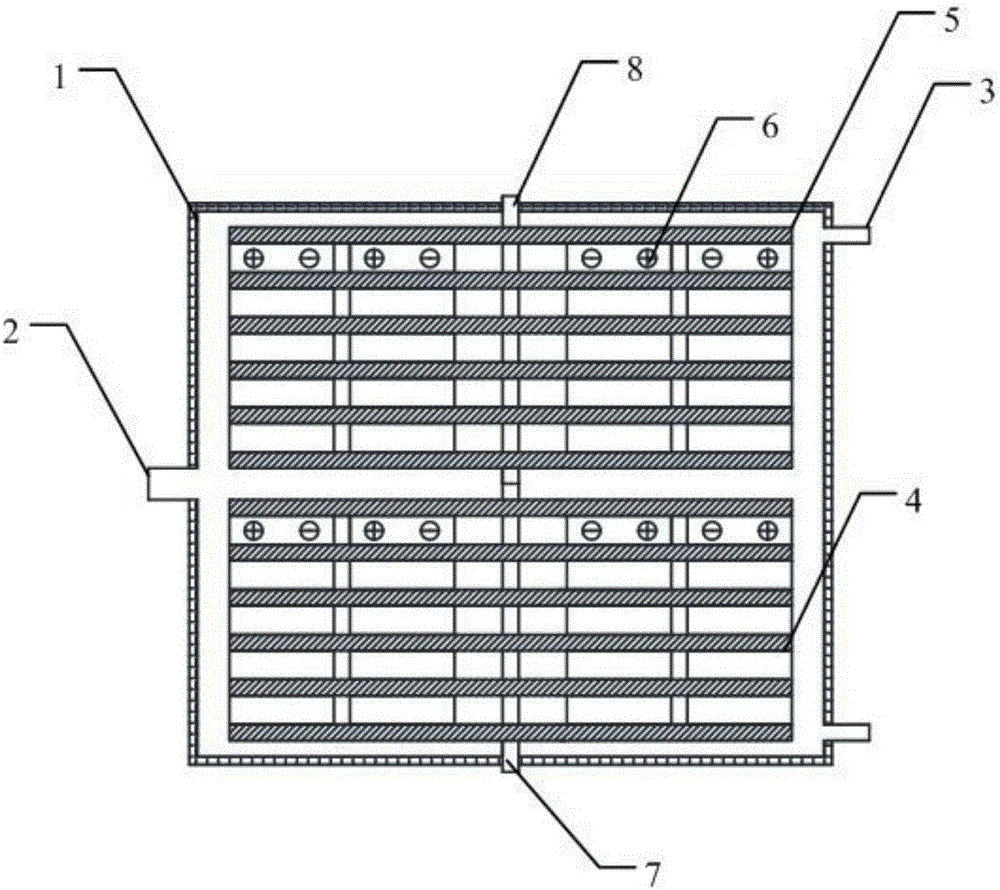

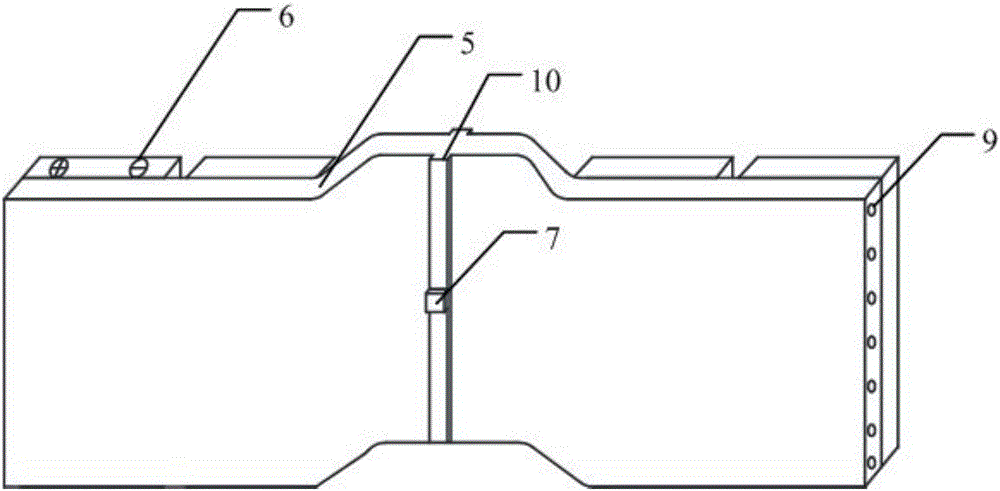

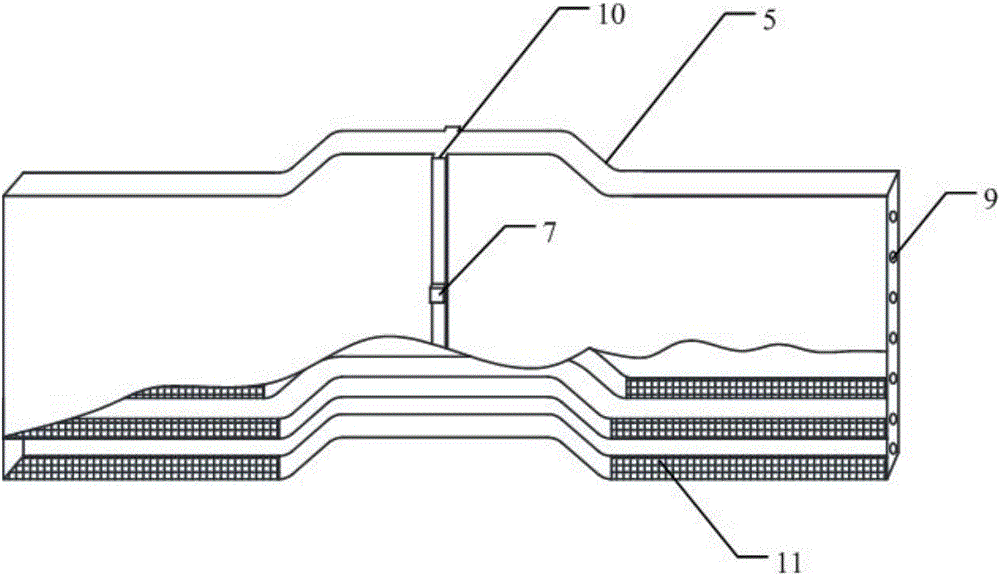

[0041] see below Figure 1 to Figure 6 , to illustrate an embodiment of a battery cooling device in the present invention:

[0042] A battery cooling device of the present invention includes: a battery pack 1, a layered flat heat pipe 5 and a cooling flow channel 13; the battery pack 1 includes N battery modules 4, and each battery module 4 includes M batteries arranged side by side The single battery 6, M and N are natural numbers; the layered flat heat pipe 5 is closely attached between the two single batteries 6; the cooling flow channel 13 runs through a plurality of layered flat heat pipes 5 horizontally; one end of the cooling flow channel 13 There is a cooling liquid inlet 7 and the other end has a cooling liquid outlet 8 , and the cooling liquid flows into the flat heat pipe 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com