Variable inertia control method and device for servo system

A technology of a servo system and a control method is applied in the field of variable inertia control of the servo system to achieve the effects of sudden change in inertia, convenient debugging and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical solutions adopted by the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is only suitable for illustrating and explaining the present invention, and does not constitute a limitation to the protection scope of the present invention.

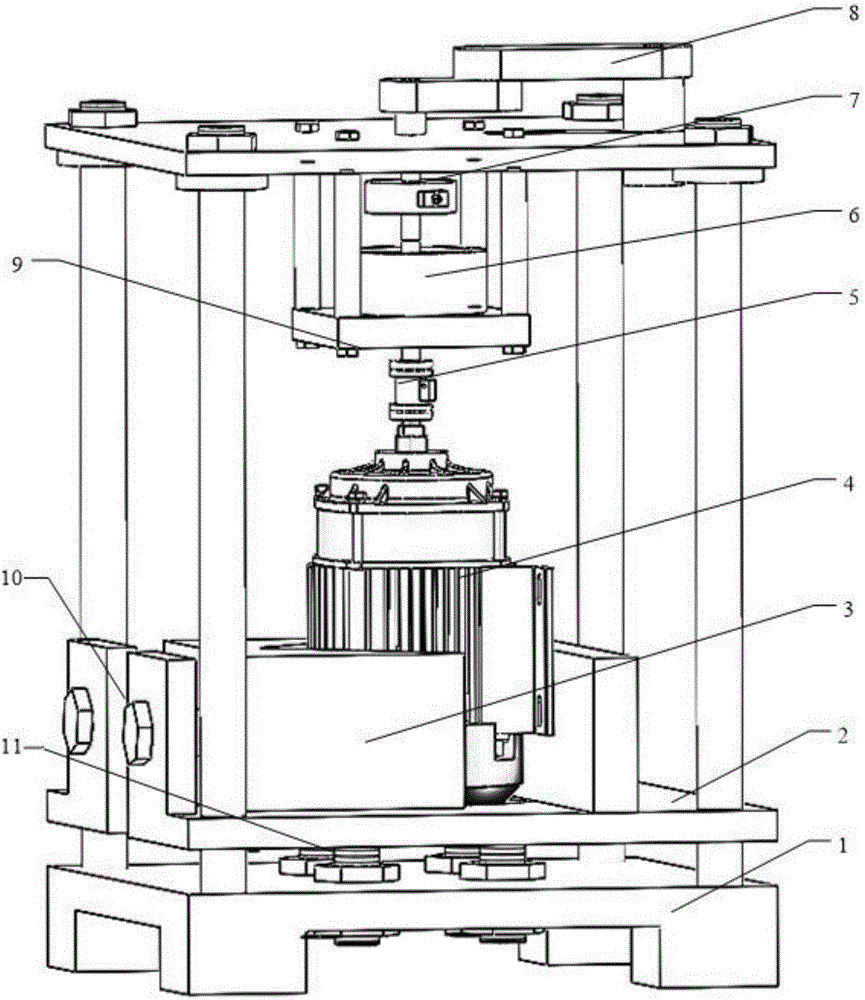

[0034] Such as figure 1 As shown, a servo system variable inertia device of the present invention includes a base 1, a lifting platform 2, a motor fixing device 3, a permanent magnet synchronous motor 4, a torque sensor 5, a magnetic powder clutch 6, an absolute photoelectric encoder 7, Slider crank mechanism 8, drag table 9, pre-tightening bolt 10 and fastening nut 11. The lifting platform 2 is movably arranged on the column of the base 1, and its position is adjusted by fastening nuts 11; the motor fixing device 3 is connected with the lifting platform 2 through pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com