Improved submerged arc furnace electrode feed device

A technology of power feeding device and submerged arc furnace, which is applied in the direction of electric heating device, electrical components, heating through discharge, etc., can solve the problems of poor cooling effect of copper tiles, low production efficiency, thermal power failure of submerged arc furnace, etc., and achieve economic benefits And significant social benefits, high production efficiency, power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

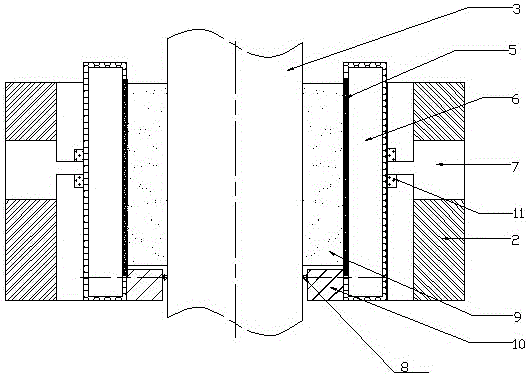

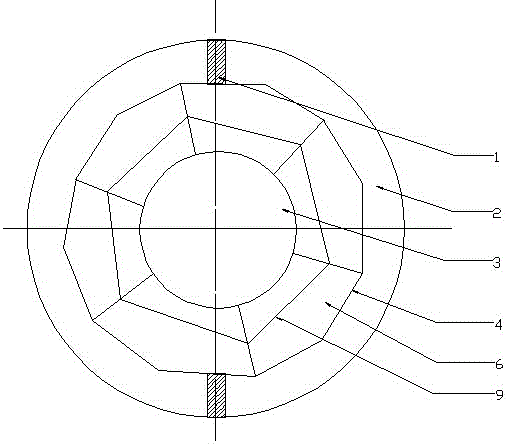

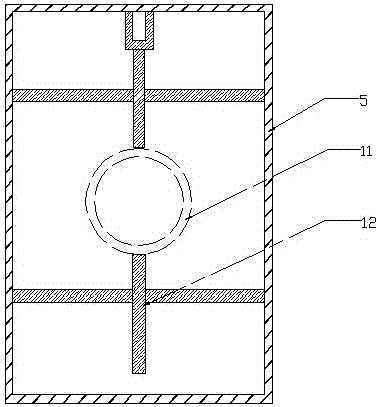

[0013] Such as figure 1 and figure 2 Shown: an improved submerged arc furnace electrode feeder; including electrodes 3, graphite lining 9, a circulating cooling water jacket 6 with a conductive plate 5 on the inner ring and a holding device; the outer side of the lower part of the inner ring of the circulating cooling water jacket 6 A support base 10 is fixedly connected with a stud 8, and a graphite lining 9 is installed above the support base 10.

[0014] Compared with the technology of the patent No. 200720153032.0 described in the background technology, the support seat at the lower end of the circulating cooling water jacket is changed to a detachable single body. After the submerged arc furnace runs to a certain period, due to the continuous oxidation of graphite lining 9, When the volume is deformed and cannot be in close contact with the electrode 3, it needs to be replaced. For the convenience of replacement, the supporting base 10 is removed, and after a new grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com