Water circulation use method and system for bean sprout culture

A technology of water circulation and bean sprouts, applied in chemical instruments and methods, botany equipment and methods, applications, etc., can solve problems such as reducing the quality of mung bean sprouts and soybean sprouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

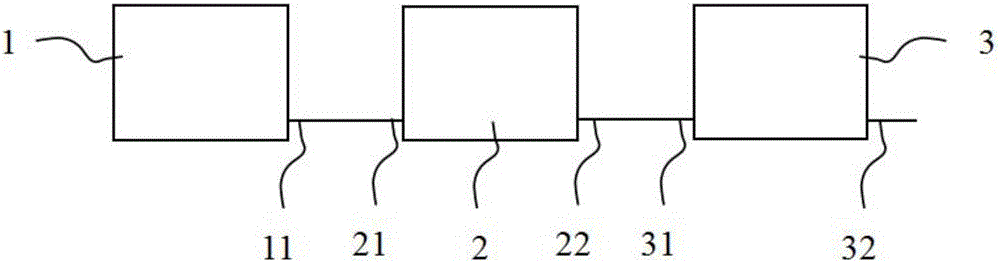

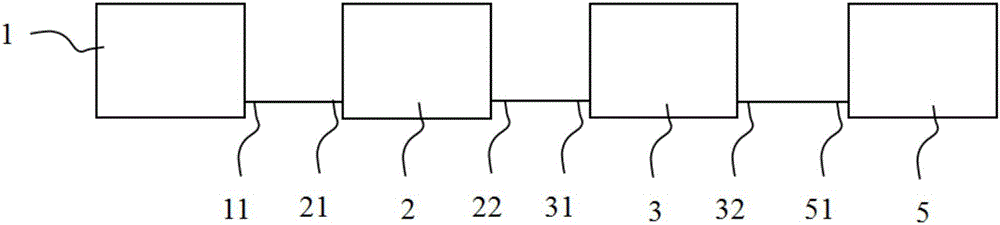

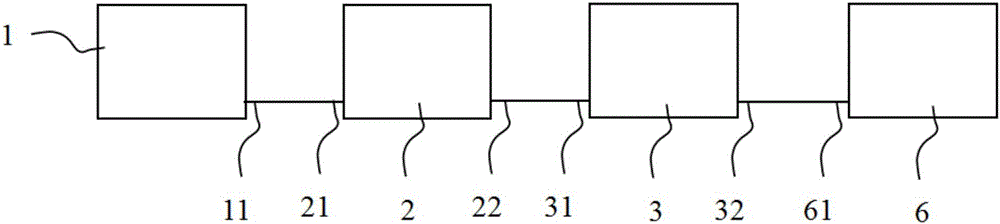

Image

Examples

Embodiment 1

[0091] 1. Recycle the water for cultivating mung bean sprouts and put it in the recycling water tank.

[0092]2. Combined disinfection of recycled water through ultraviolet / ozone combined equipment, controlling the irradiation dose of ultraviolet rays to 12MJ / cm 2 , the concentration of ozone in recycled water is 2mg / L.

[0093] 3. Pass the water into the quartz sand filter equipment for filtration. The quartz sand layer is composed of quartz sand with a particle size of 1.2-2.4mm and a thickness of 500mm. Then through the activated carbon filter equipment, the activated carbon layer is composed of an activated carbon filter material layer with a particle size of 0.6-2.75mm and a thickness of 700mm and an activated carbon layer with a particle size of 3-8mm and a thickness of 700mm. Control the initial filtration rate of the quartz sand filter equipment to be 8m / h. Filtration is completed to obtain purified water.

Embodiment 2

[0095] 1. Recycle the water for cultivating mung bean sprouts and put it in the recycling water tank.

[0096] 2. Combined disinfection of recycled water through ultraviolet / ozone combined equipment, controlling the irradiation dose of ultraviolet rays to 140MJ / cm 2 , the concentration of ozone in recycled water is 0.4mg / L.

[0097] 3. Pass the water into the quartz sand filter equipment for filtration. The quartz sand layer is composed of quartz sand with a particle size of 1.2-2.4mm and a thickness of 500mm. Then through the activated carbon filter equipment, the activated carbon layer is composed of an activated carbon filter material layer with a particle size of 0.6-2.75mm and a thickness of 700mm and an activated carbon layer with a particle size of 3-8mm and a thickness of 700mm. Control the initial filtration rate of the quartz sand filter equipment to be 15m / h. Filtration is completed to obtain purified water.

Embodiment 3

[0099] 1. Recycle the water for cultivating mung bean sprouts and put it in the recycling water tank.

[0100] 2. Combined disinfection of recycled water through ultraviolet / ozone combined equipment, controlling the irradiation dose of ultraviolet rays to 40MJ / cm 2 , the concentration of ozone in recycled water is 1.2mg / L.

[0101] 3. Pass the water into the quartz sand filter equipment for filtration. The quartz sand layer is composed of quartz sand with a particle size of 1.2-2.4mm and a thickness of 500mm. Then through the activated carbon filter equipment, the activated carbon layer is composed of an activated carbon filter material layer with a particle size of 0.6-2.75mm and a thickness of 700mm and an activated carbon layer with a particle size of 3-8mm and a thickness of 700mm. Control the initial filtration rate of the quartz sand filter equipment to be 12m / h. Filtration is completed to obtain purified water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com