Mounting locating device for flushing spraying system of wet electrical dust precipitator

A technology of wet electrostatic precipitator and spray system, which is applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., which can solve the problems of long installation period, long distance of spray pipe, deformation of spray pipe, etc., to reduce installation Work strength, easy and fast installation, and the effect of reducing installation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

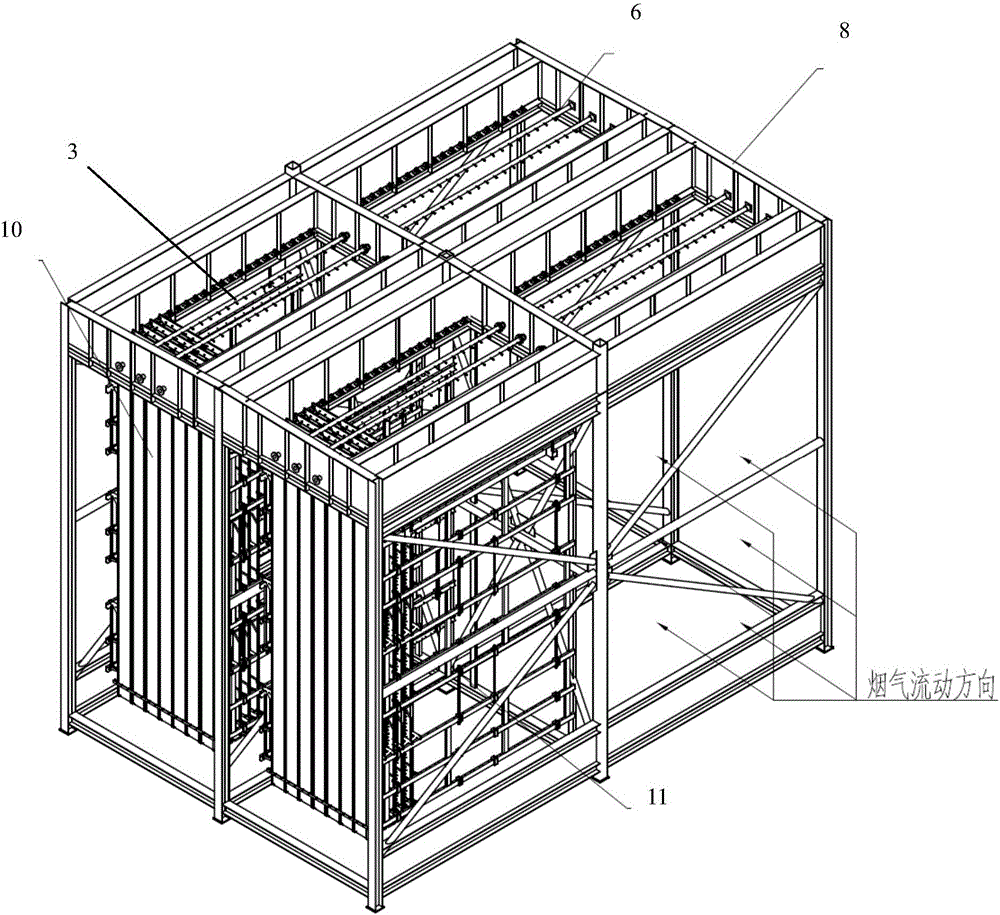

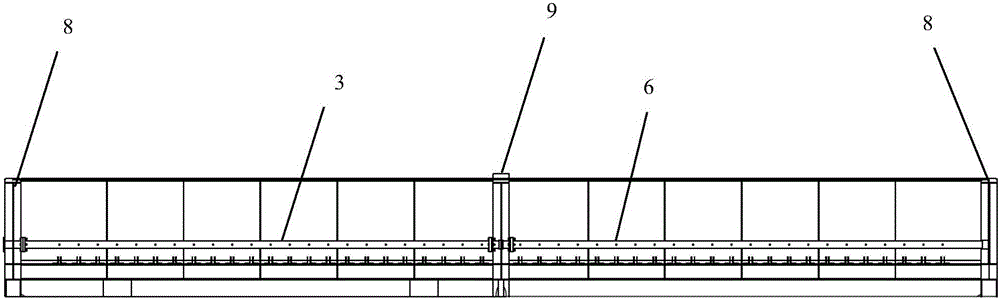

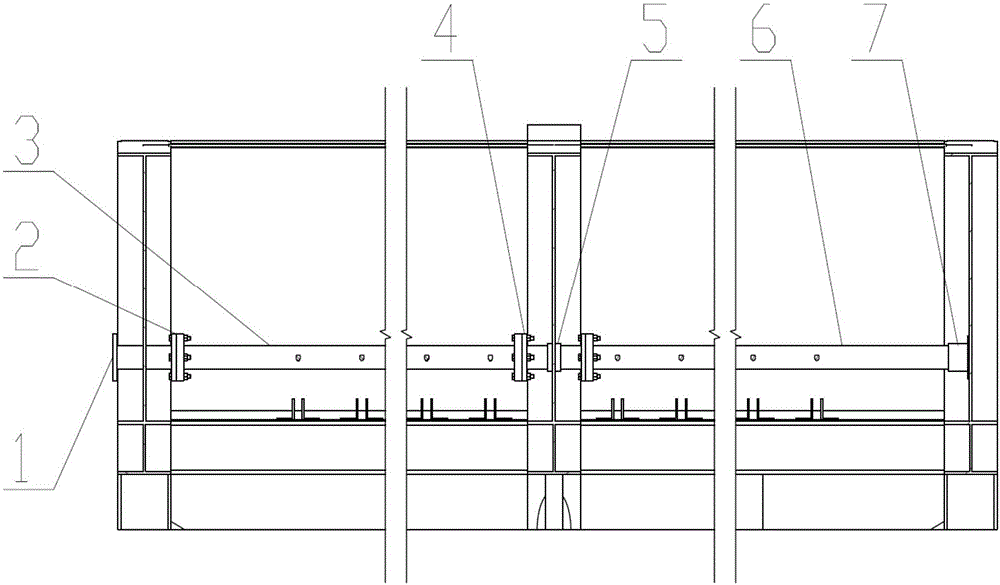

[0023] Such as Figure 1 to Figure 5 As shown, the installation and positioning device for the flushing and spraying system of the wet electrostatic precipitator includes the top side girder 8, the middle frame top beam 9, the limit sleeve 7, the sleeve 5 and the middle connecting pipe 4; The top side girders 8 are two respectively arranged on both sides of the middle frame top girder 9, the limit sleeve 7 is fixed on the top side girder 8 on one side, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com