Automatic canning equipment for honey

A canning equipment and automatic technology, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of large air bubbles, slow filling speed, and affecting honey production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the technical solution of the present invention will be described in detail through specific examples.

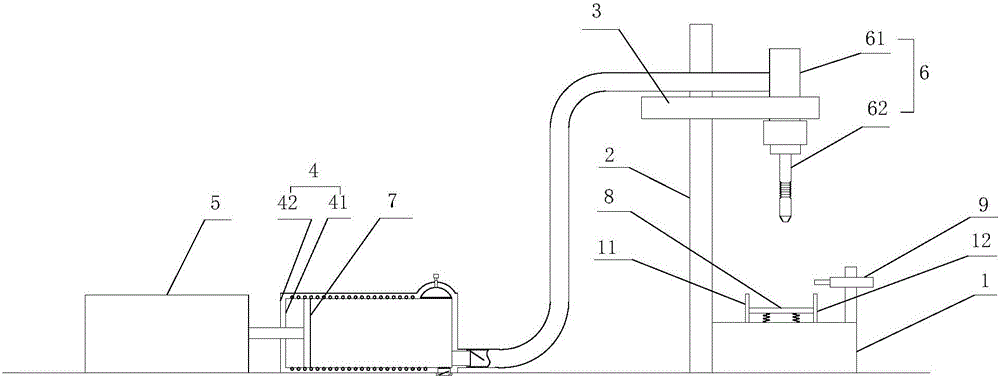

[0025] like figure 1 as shown, figure 1 It is a structural schematic diagram of a honey automatic canning equipment proposed by the present invention.

[0026] refer to figure 1 , a kind of automatic honey canning equipment proposed by the embodiment of the present invention, comprising: a base 1, a material injection device, a material storage container, a first transmission device, a second transmission device, a driving device and a control device, wherein:

[0027] The base 1 is arranged horizontally. On the upper surface of the base 1, there are oppositely arranged first side panels 11 and second side panels 12. Between the first side panels 11 and the second side panels 12 are formed for the passage of the charging tank and two The end-through feeding channel; the side where the feeding channel extends is provided with a vertically arranged guide rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com