Sodium sulfocyanate caking prevention apparatus and method thereof

A technology of sodium thiocyanate and anti-caking agent, applied in the direction of thiocyanic acid, etc., can solve the problems of not being able to fundamentally guarantee the anti-caking effect and uneven mixing, so as to achieve not easy caking, easy caking, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of the present invention is not limited thereto. Unless otherwise specified, the operations used in the following examples are conventional methods, and the components and consumables used are all commercially available.

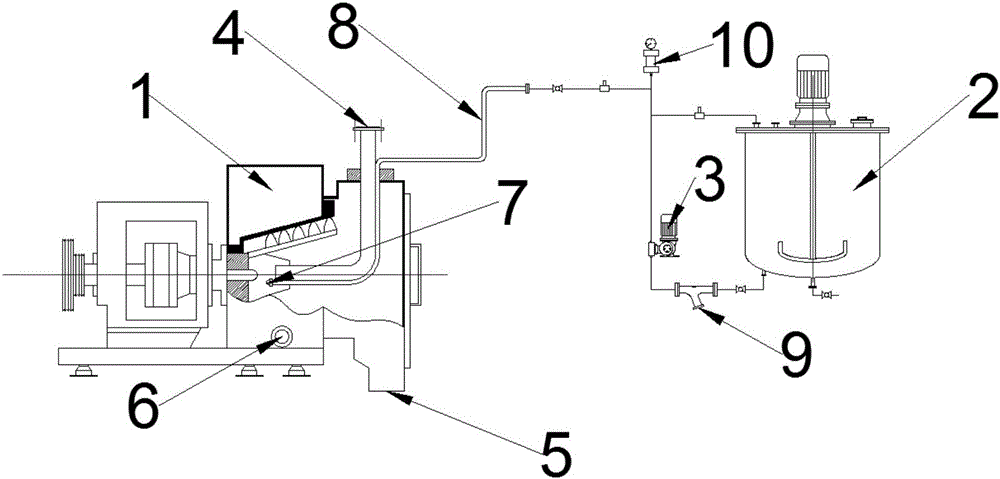

[0031] Such as figure 1 Shown, in all embodiments provided by the present invention, the device that prevents sodium thiocyanate from agglomerating described in the present invention all has following common features: described device comprises liquid mixing tank 2, is used for preparing anti-caking agent Solution; liquid inlet pipe 8, spray nozzle 7, feed port 4 and horizontal screw centrifuge 1; one end of the liquid inlet pipe 8 is connected to the liquid distribution tank 2, and the other end is provided with a spray nozzle 7, which is connected to the horizontal spiral centrifuge The centrifuges 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com