Aluminum alloy copper salt coloring electrophoresis process

An aluminum alloy and electrophoresis technology, applied in electrophoretic plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems such as hindering copper coloring electrophoretic alloy profiles from gas, easy to appear color difference, etc., to achieve uniform and stable coloring, sealing time Long-lasting, anti-dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

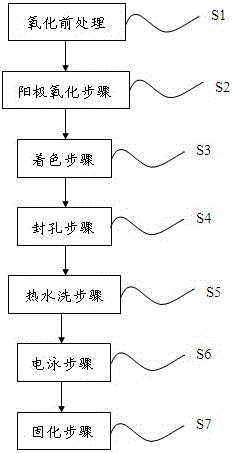

[0047] The aluminum alloy copper salt coloring electrophoresis process is as follows:

[0048] S1 Pre-oxidation treatment: Prepare a sulfuric acid bath and install the alloy profiles to be colored on the rack. The bath must be stirred in advance, and the alloy profiles in the same row must have the same model.

[0049] S2 anodizing step: Put the alloy profile into a sulfuric acid bath and anodic oxidation to generate an oxide film with film holes.

[0050] The current density of the sulfuric acid bath used in this embodiment is 125A / dm 2 , The temperature of the sulfuric acid bath is 20°C.

[0051] S3 coloring step: Put the anodized profile obtained in step S2 into a copper salt electrolytic coloring tank for electrolytic coloring, and use copper wires to achieve electrical connection.

[0052] Wherein, the bath solution of the copper salt electrolytic coloring tank contains copper sulfate pentahydrate and sulfuric acid, the concentration of copper sulfate pentahydrate is 14g / L, the con...

Embodiment 2

[0060] The aluminum alloy copper salt coloring electrophoresis process is as follows:

[0061] S1 Pre-oxidation treatment: Prepare a sulfuric acid bath and install the alloy profiles to be colored on the rack. The bath must be stirred in advance, and the alloy profiles in the same row must have the same model.

[0062] S2 anodizing step: Put the alloy profile into a sulfuric acid bath and anodic oxidation to generate an oxide film with film holes.

[0063] The current density of the sulfuric acid bath used in this example is 135A / dm 2 , The temperature of the sulfuric acid bath is 23°C.

[0064] S3 coloring step: Put the anodized profile obtained in step S2 into a copper salt electrolytic coloring tank for electrolytic coloring, and use copper wires to achieve electrical connection.

[0065] Wherein, the bath solution of the copper salt electrolytic coloring tank contains copper sulfate pentahydrate and sulfuric acid, the concentration of copper sulfate pentahydrate is 16 g / L, the conce...

Embodiment 3

[0073] The aluminum alloy copper salt coloring electrophoresis process is as follows:

[0074] S1 Pre-oxidation treatment: Prepare a sulfuric acid bath and install the alloy profiles to be colored on the rack. The bath must be stirred in advance, and the alloy profiles in the same row must have the same model.

[0075] S2 anodizing step: Put the alloy profile into a sulfuric acid bath and anodic oxidation to generate an oxide film with film holes.

[0076] The current density of the sulfuric acid bath used in this embodiment is 130A / dm 2 , The temperature of the sulfuric acid bath is 22°C.

[0077] S3 coloring step: Put the anodized profile obtained in step S2 into a copper salt electrolytic coloring tank for electrolytic coloring, and use copper wires to achieve electrical connection.

[0078] Wherein, the bath solution of the copper salt electrolytic coloring tank contains copper sulfate pentahydrate and sulfuric acid, the concentration of copper sulfate pentahydrate is 15 g / L, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com