Patents

Literature

31results about How to "Long sealing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

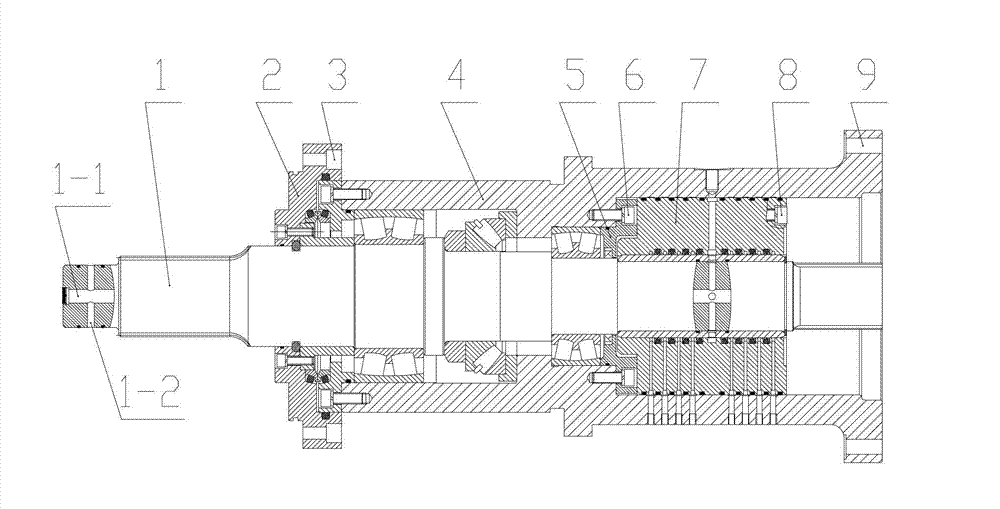

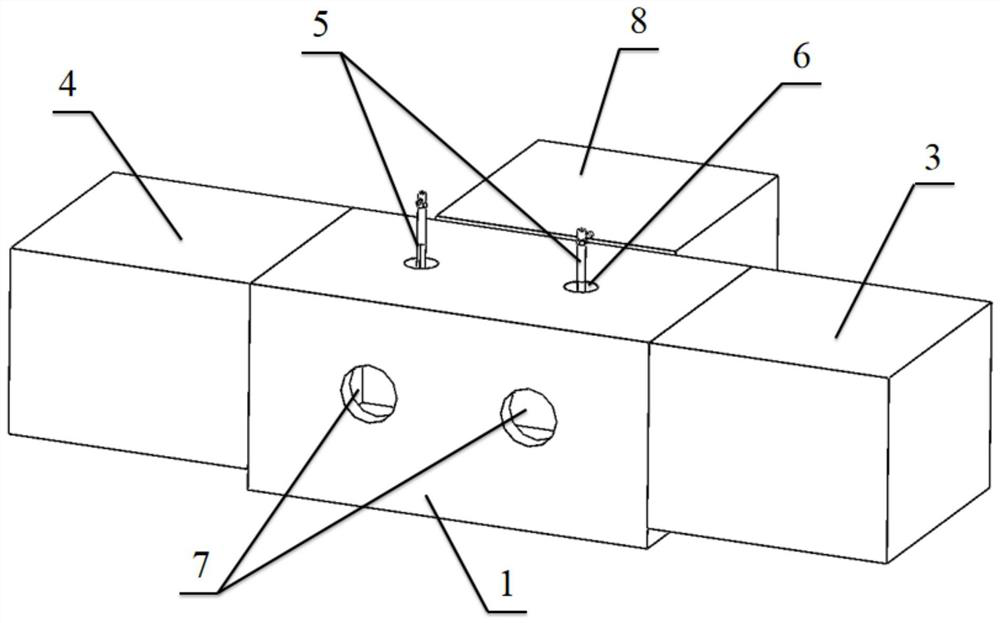

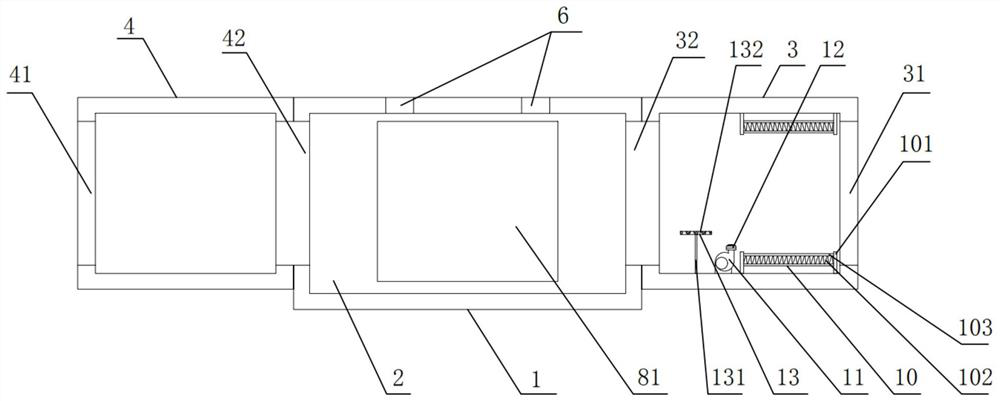

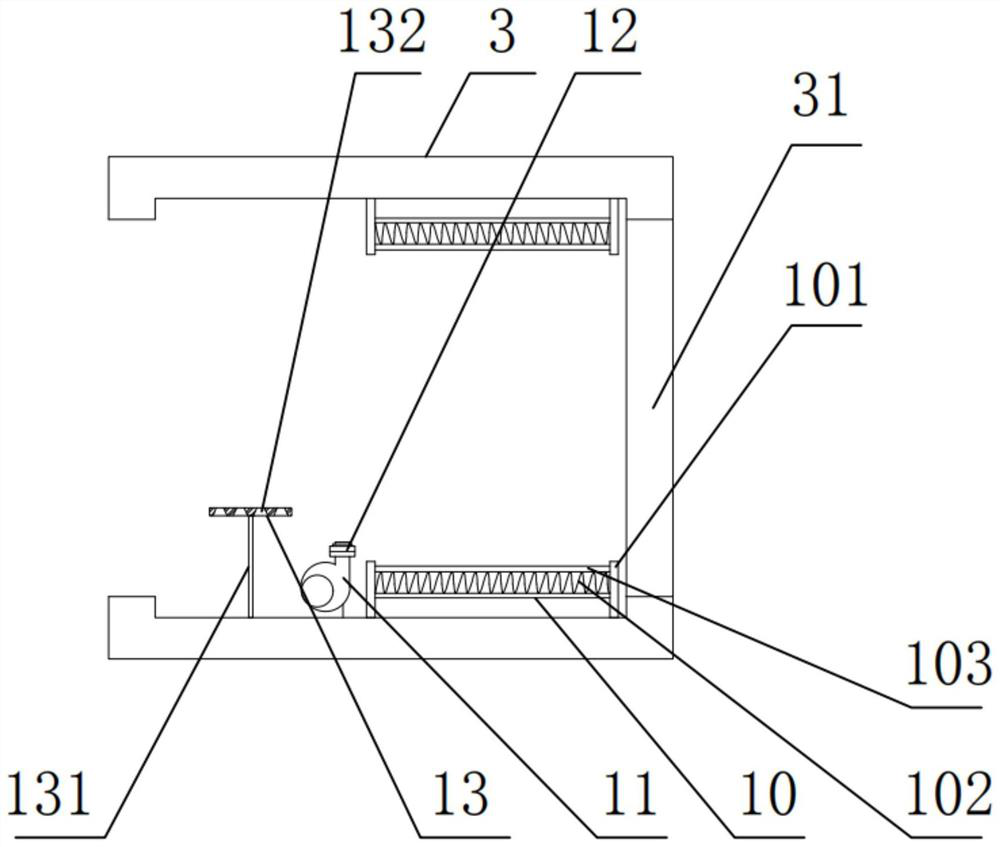

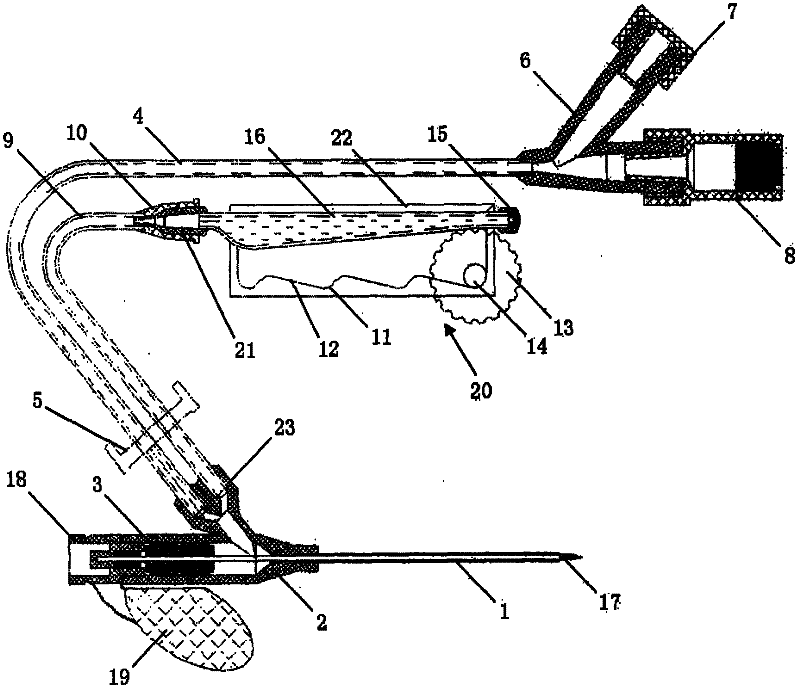

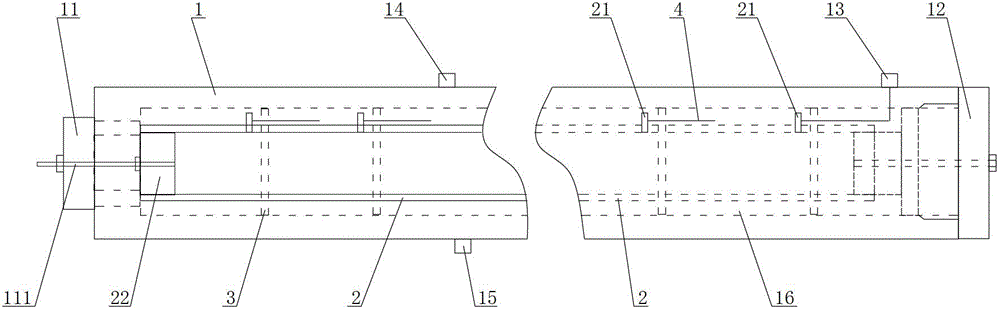

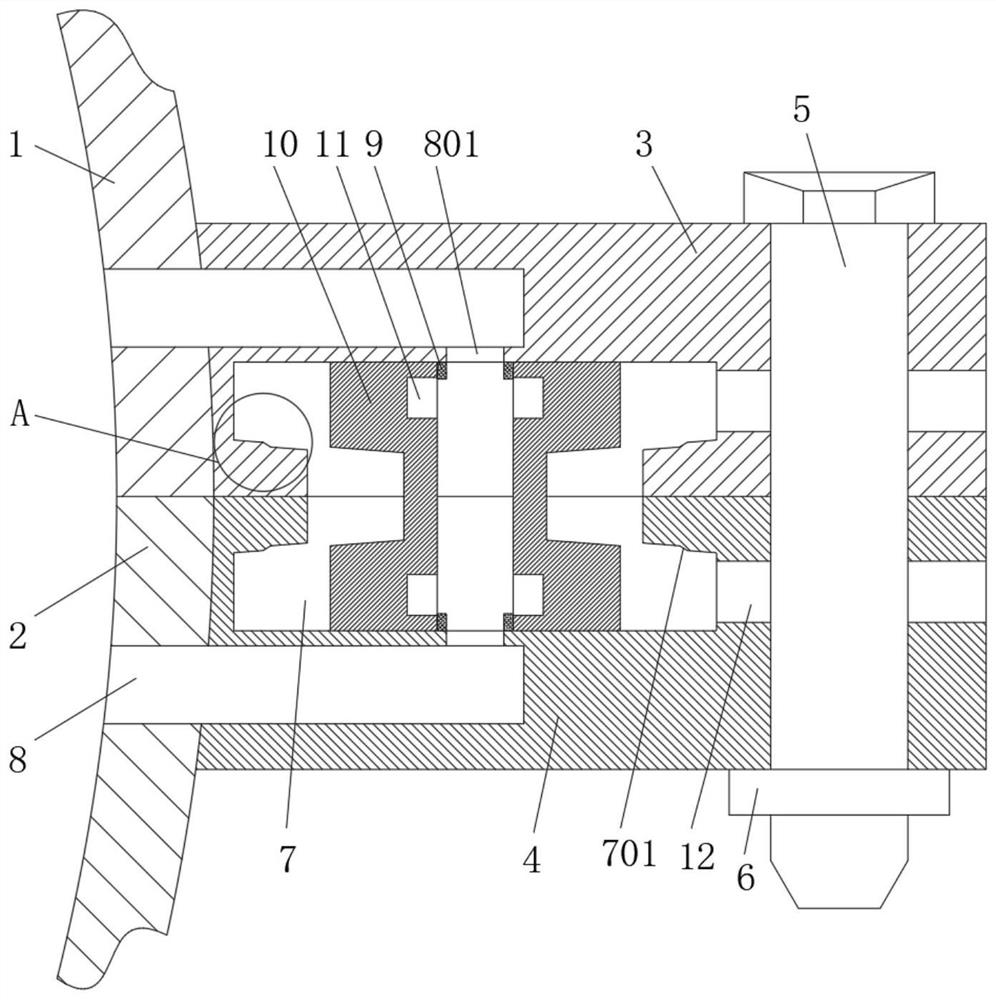

Multi-point sealing apparatus for auxiliary high-pressure water jet of cutting mechanism of digging device

ActiveCN103195423ALong sealing timeGood sealing effectSlitting machinesHydraulic miningMain channelEngineering

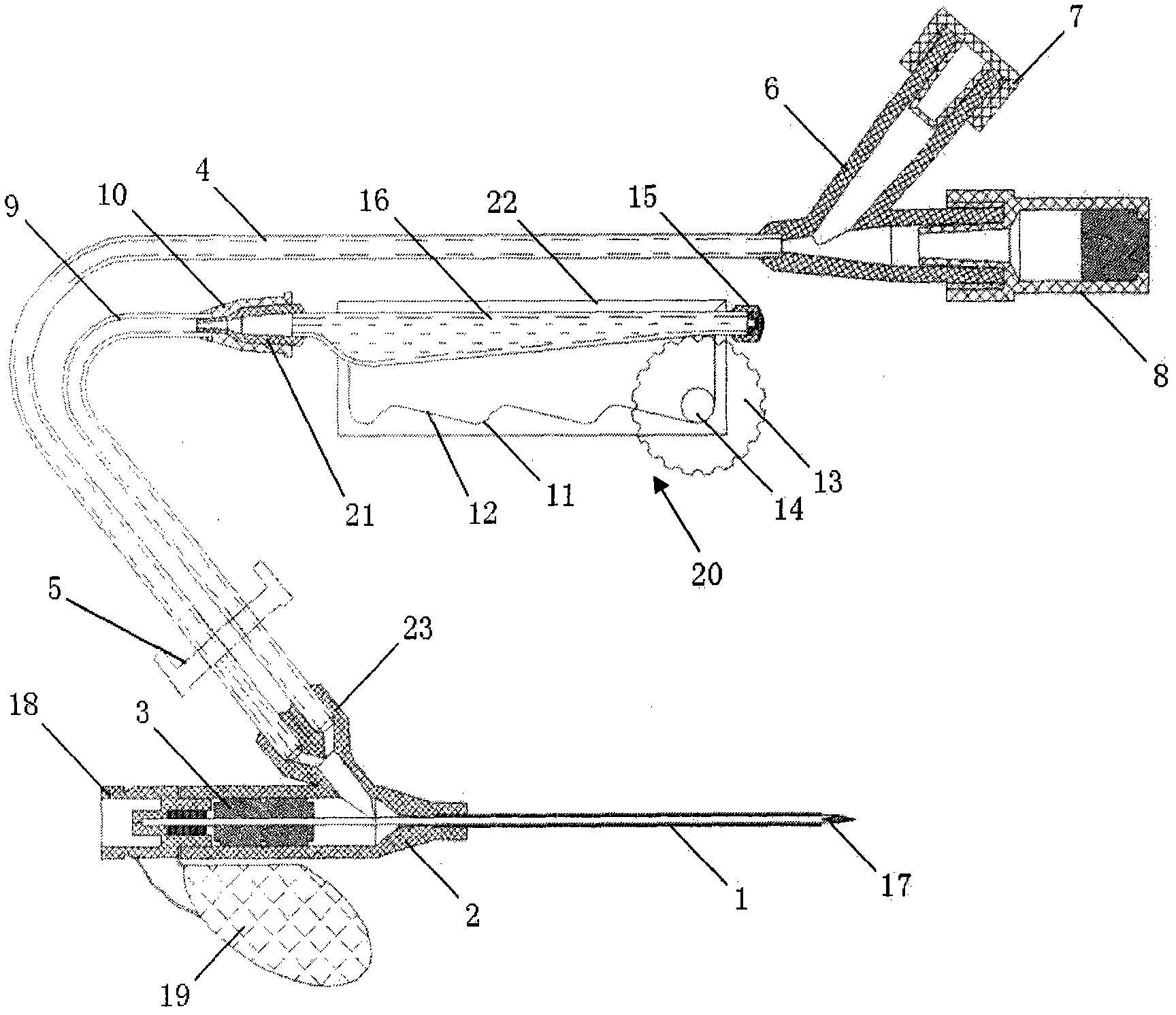

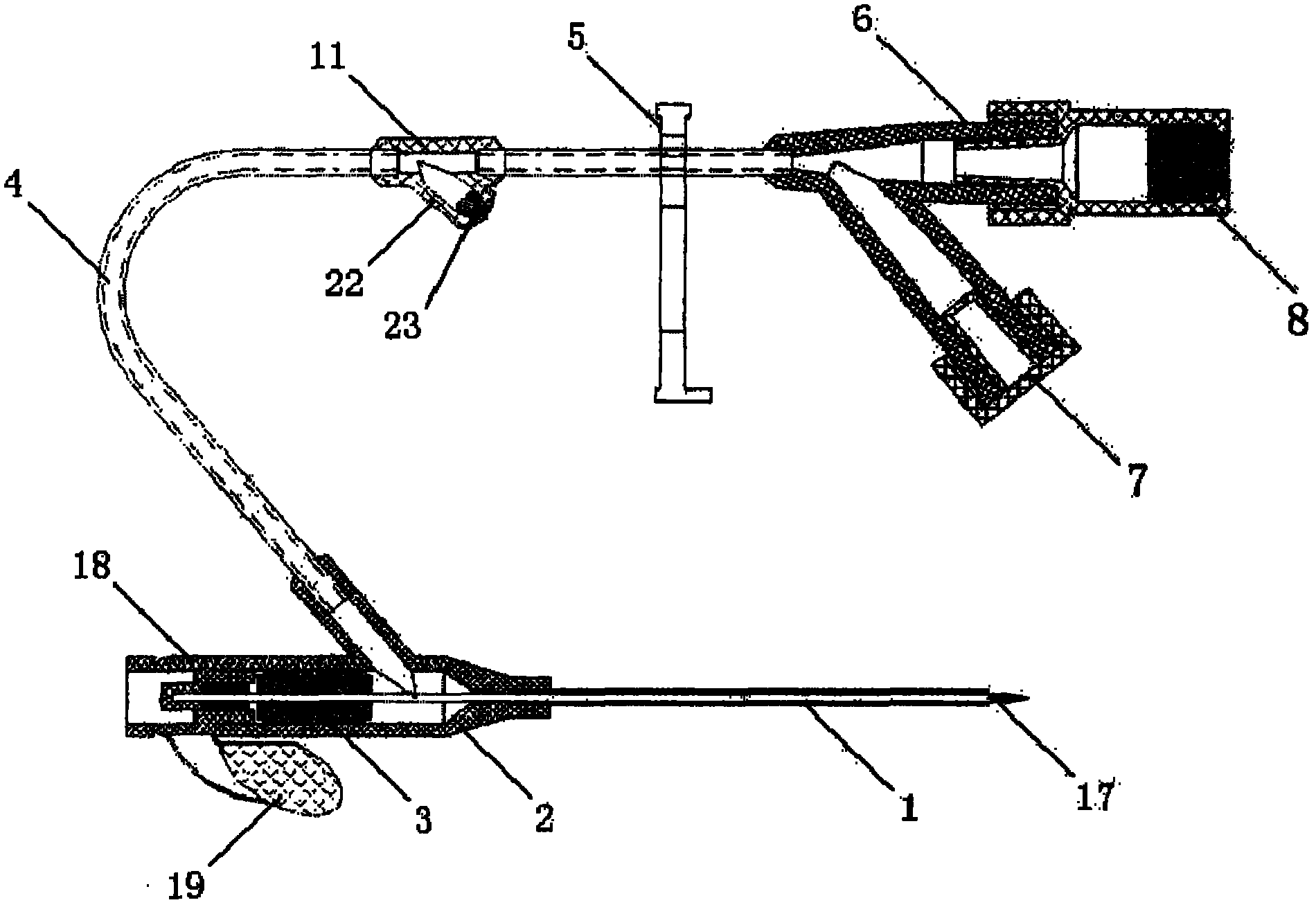

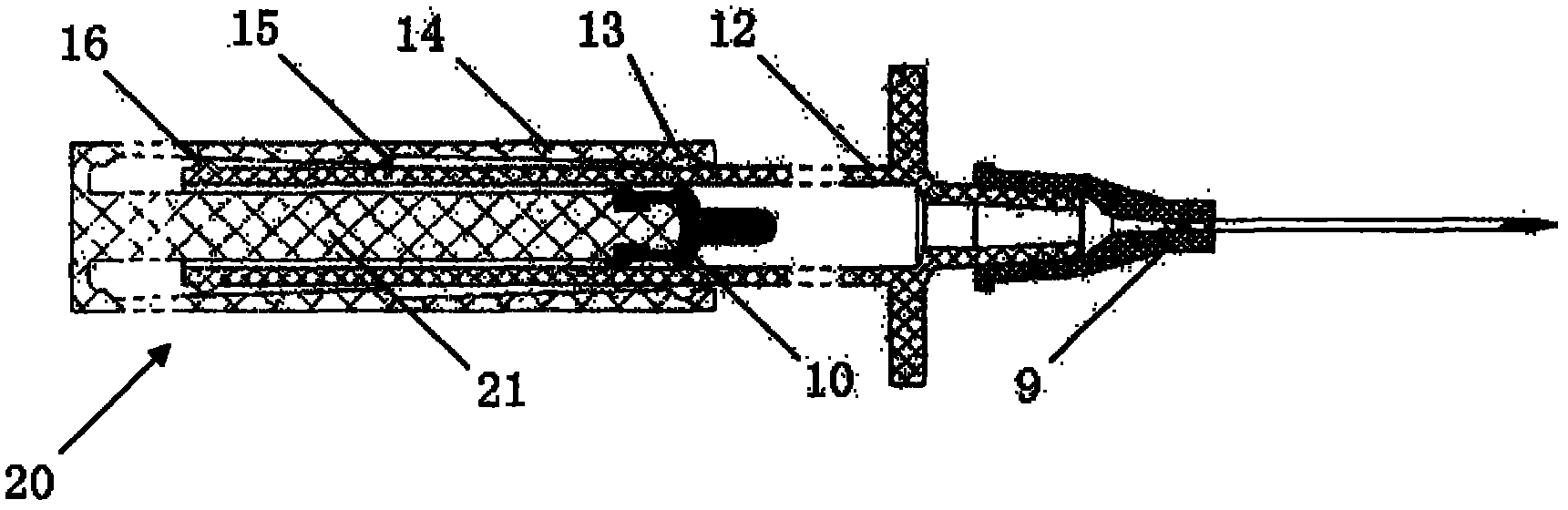

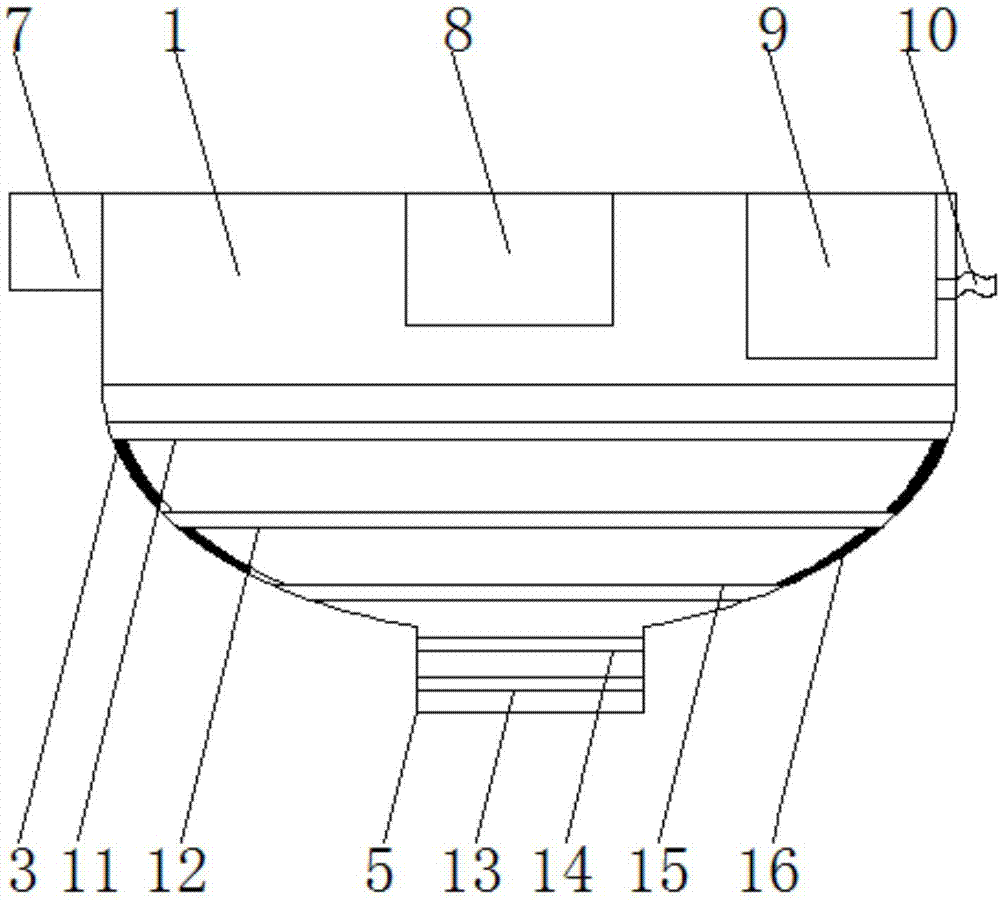

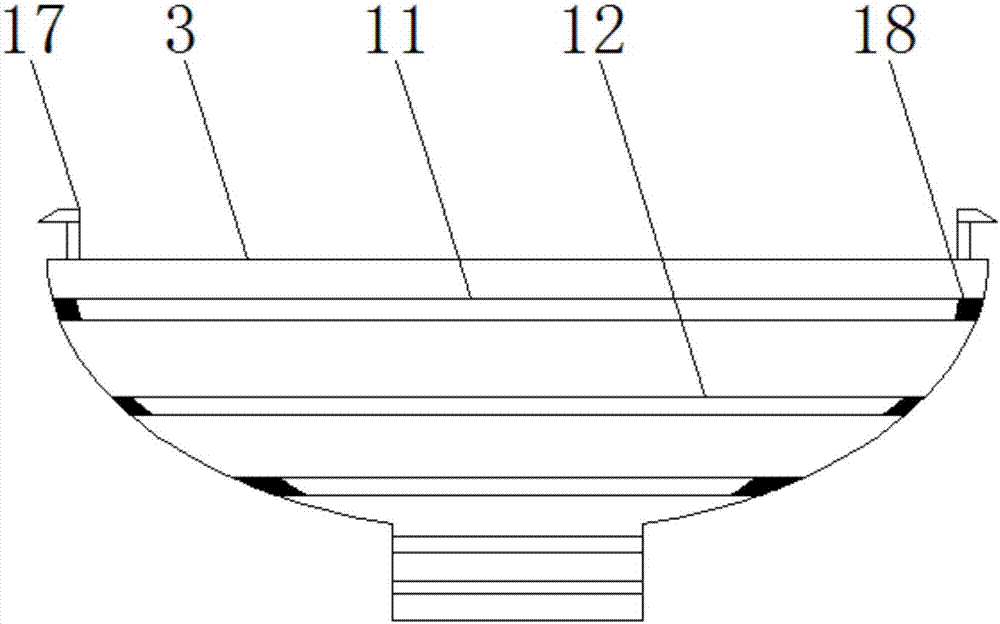

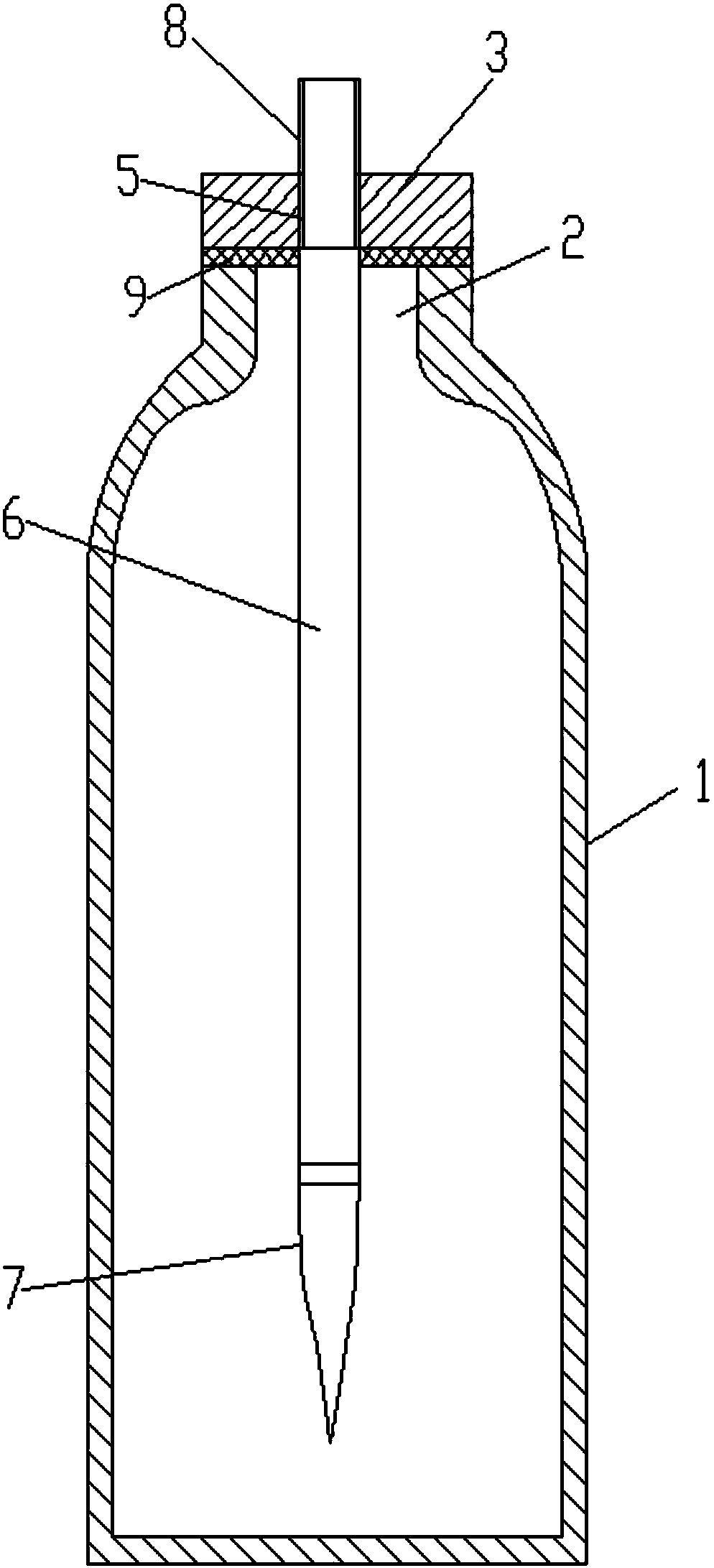

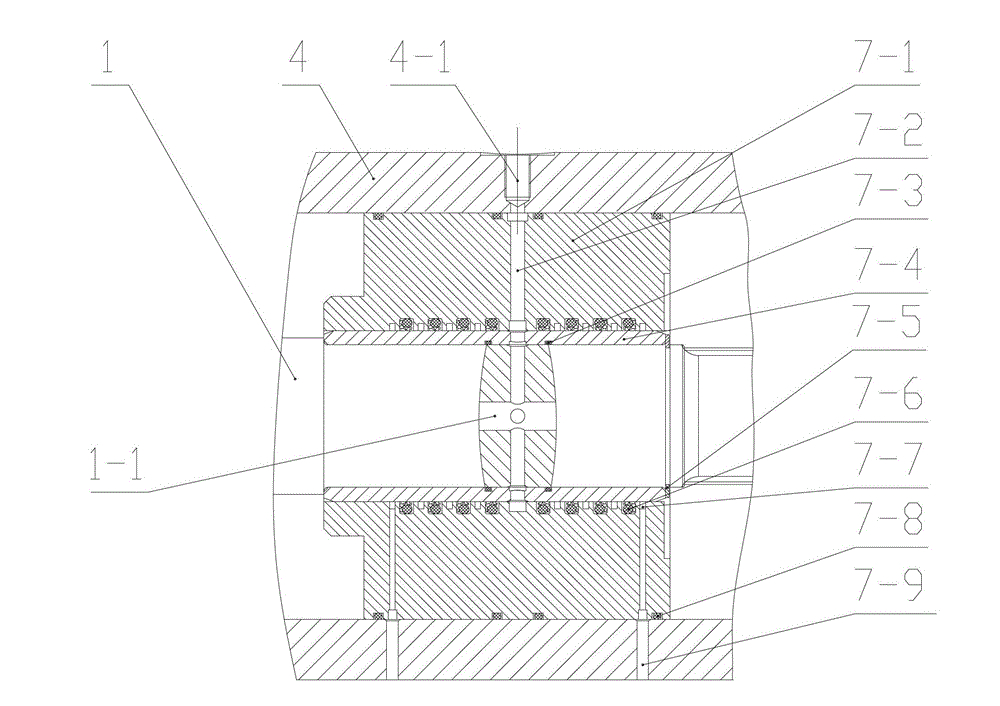

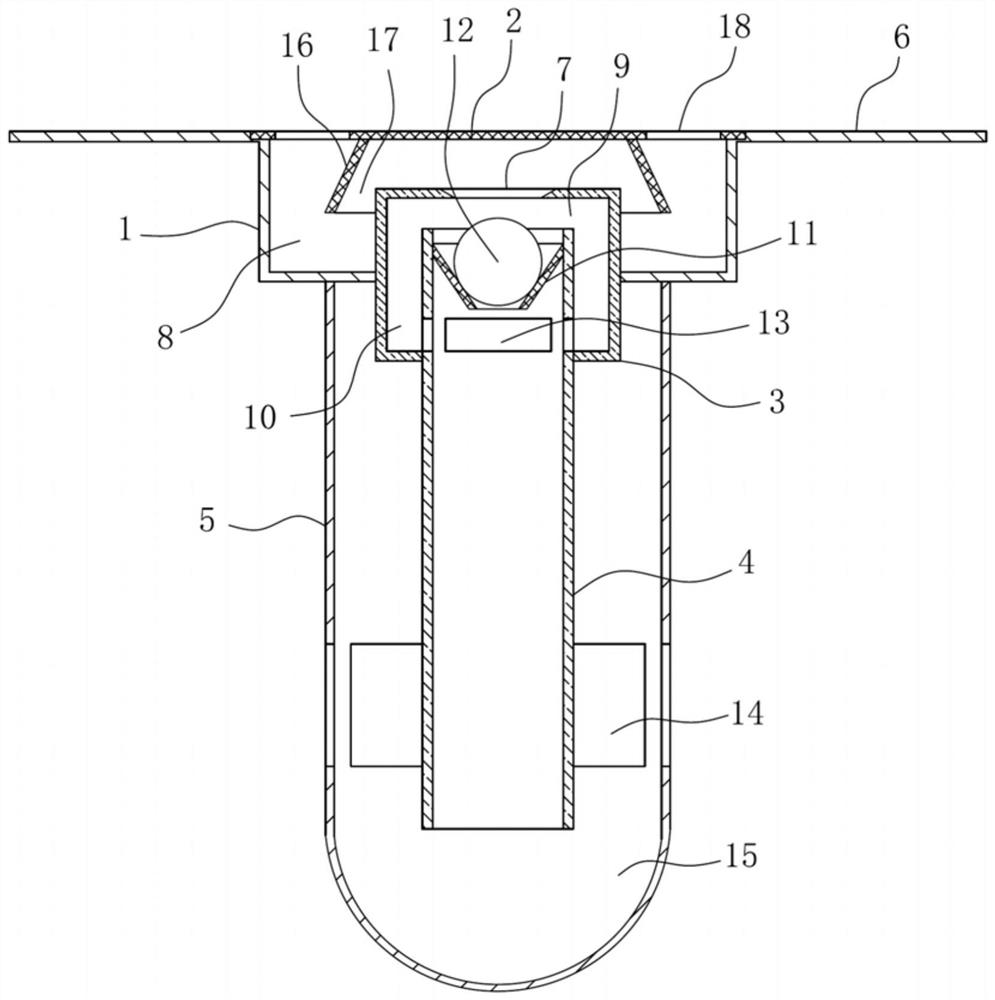

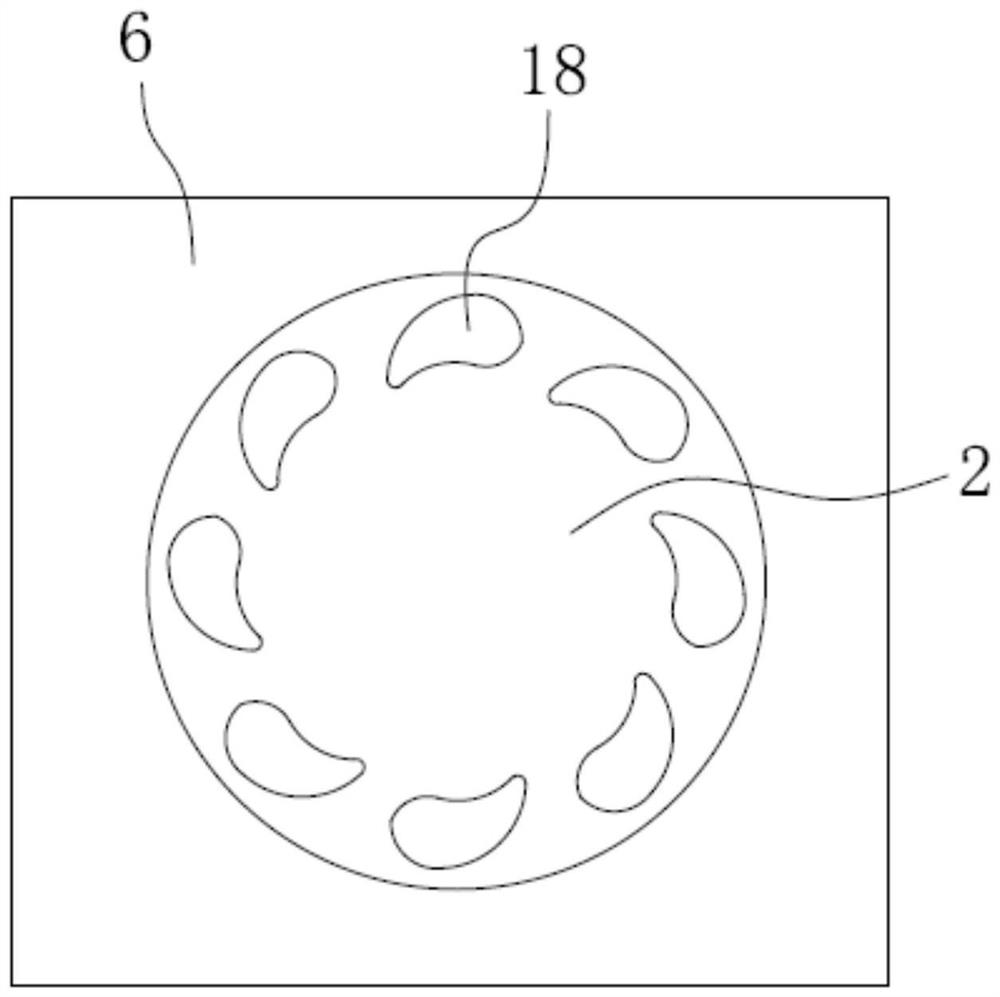

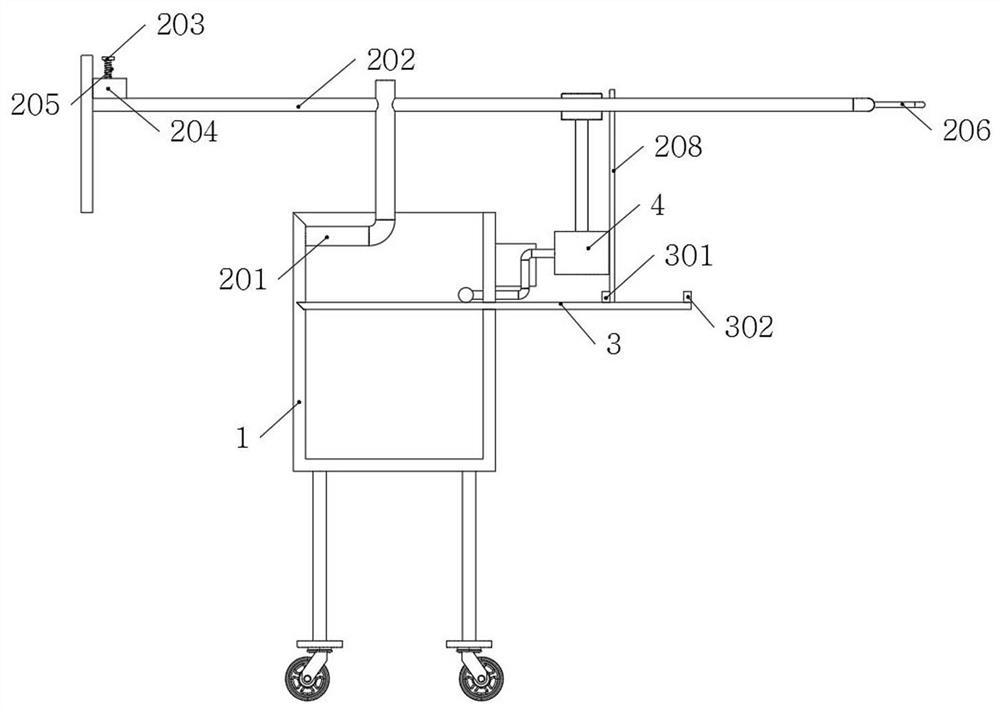

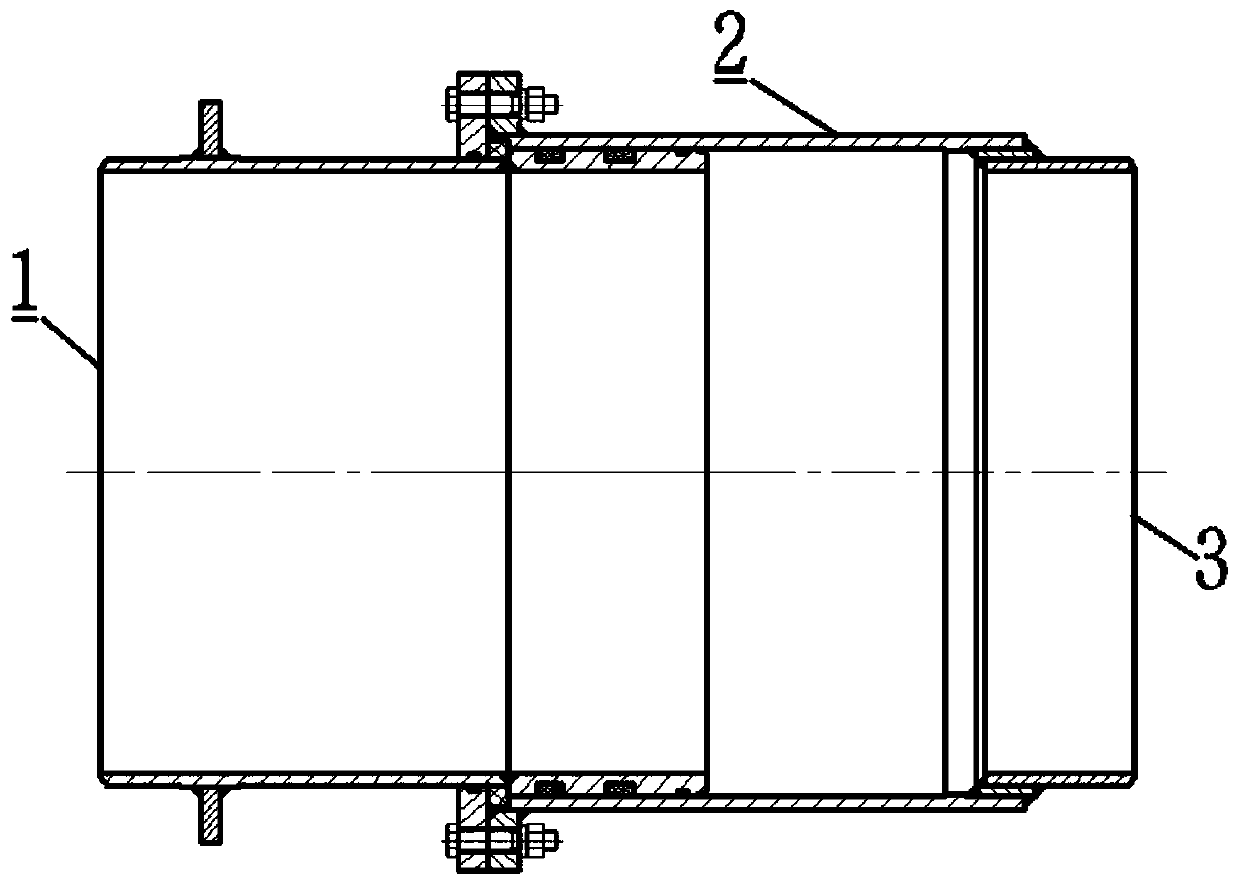

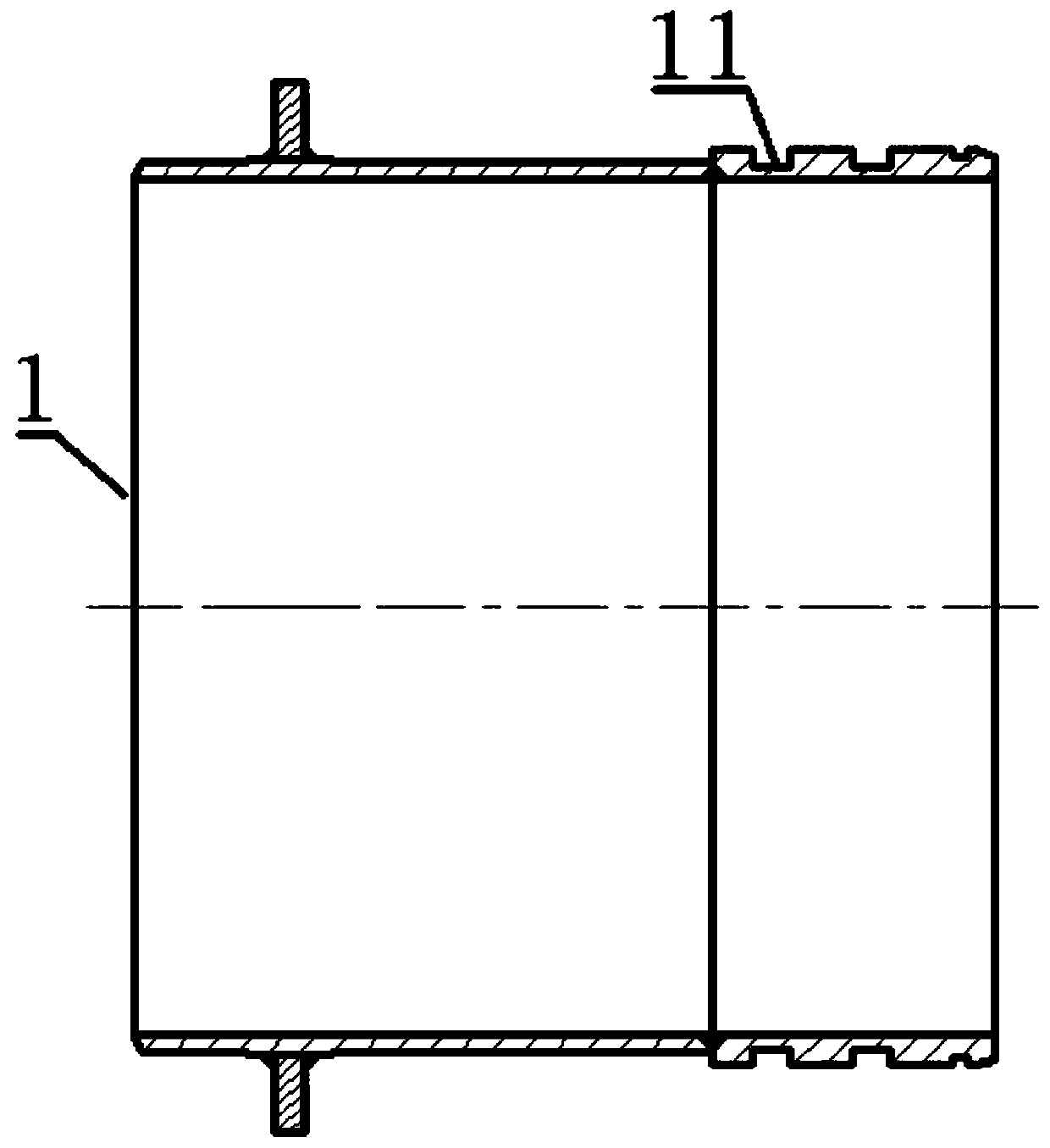

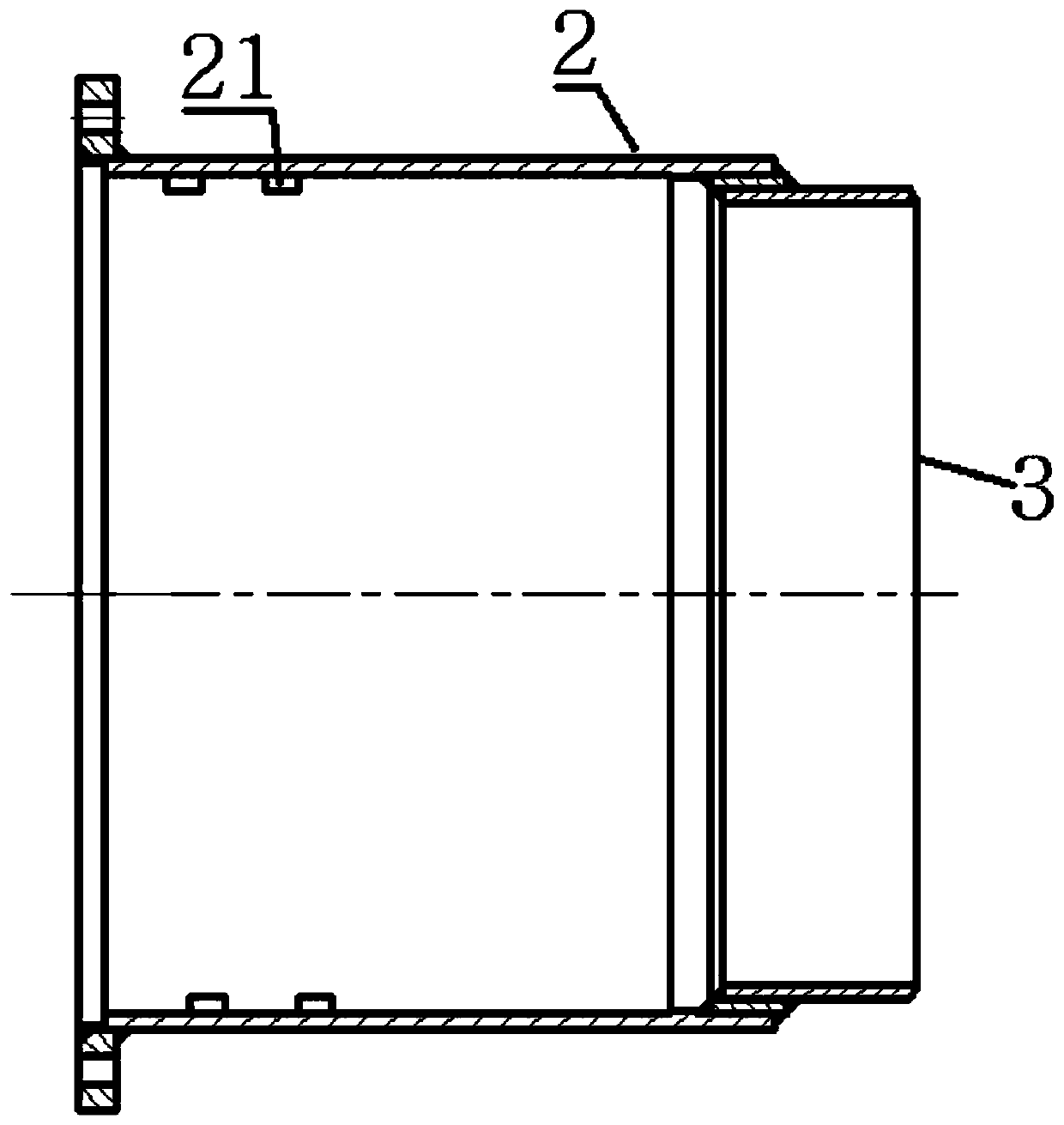

The invention discloses a multi-point sealing apparatus for an auxiliary high-pressure water jet of a cutting mechanism of a digging device. The apparatus comprises a water guide housing and a water guide sleeve which are sequentially sleeved between a cutting shaft and a cutting box of the cutting mechanism of the digging device, wherein a water inlet channel is arranged along a radial direction through the water guide housing, the water guide sleeve and the cutting shaft, the water inlet channel is respectively communicated with a water inlet of the cutting box and a main channel of the cutting shaft, two sides of the water inlet channel are respectively provided with an O-shaped sealing ring I, a tooth combination seal and an O-shaped sealing ring II, the water guide housing is provided with a sluicing groove, and the cutting box is provided with a leaking channel communicated with the sluicing groove. The multi-point sealing apparatus provided by the invention solves the sealing problem of the auxiliary high-pressure water jet of the cutting mechanism of the digging device, can effectively seal a high-pressure water with a pressure of less than 50 MPa, is long in sealing time and good in sealing effect, and improves an auxiliary cutting efficiency of the high pressure water jet.

Owner:CHINA UNIV OF MINING & TECH

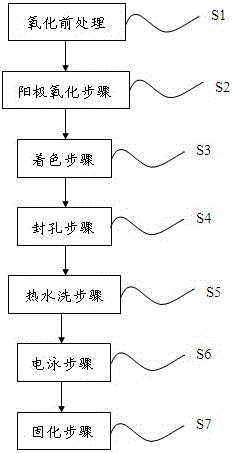

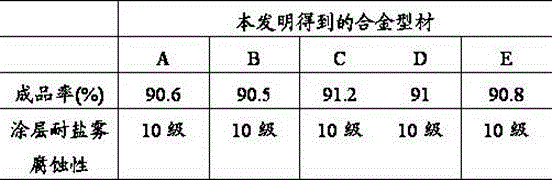

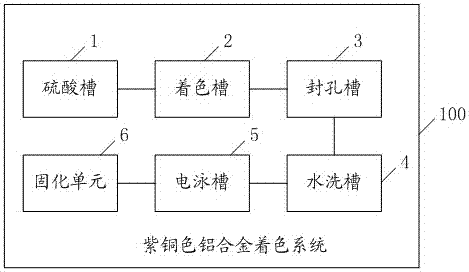

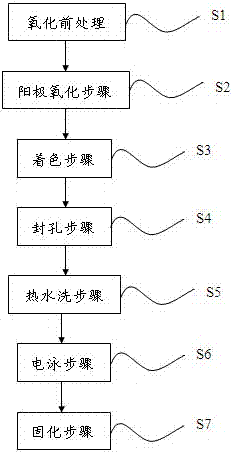

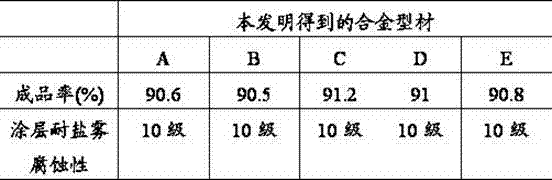

Aluminum alloy copper salt coloring electrophoresis process

ActiveCN105821461ARaise the pHLong sealing timeAnodisationElectrophoretic coatingsElectrophoresisCopper salt

The invention discloses an aluminum alloy copper salt coloring electrophoresis process. The process comprises the following steps: (1) sulfuric acid groove liquid is prepared; and an alloy profile to be colored is mounted on a lifting frame; (2) the alloy profile is put in the groove liquid for anodically oxidized to generate a layer of oxide film with a film hole; (3) the anodically oxidized alloy profile is put in a copper salt electrolytic coloring groove for electrolytic coloring; (4) the colored alloy profile is sealed; (5) the residual groove liquid in the hole sealing process is washed by water; (6) the electrophoresis is performed for the alloy profile washed by the water; and (7) the alloy profile is cured after electrophoresis. The pH value of the hole sealing groove liquid is higher; the hole sealing distance is longer; a half hole sealing process is adjusted to a near all hole sealing process for preventing dissolving of copper; and the alloy profile is more stable after coloring, and is higher in corrosion resistance.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

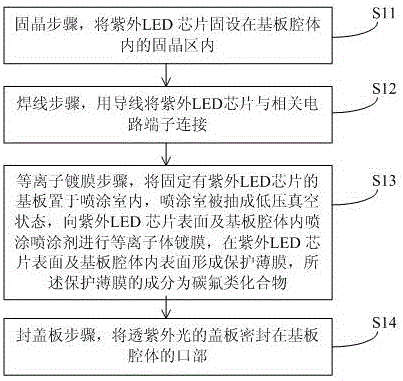

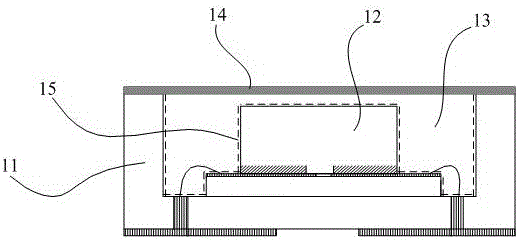

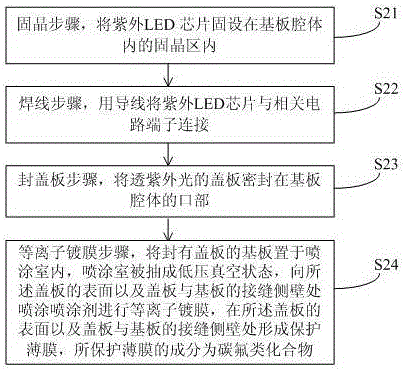

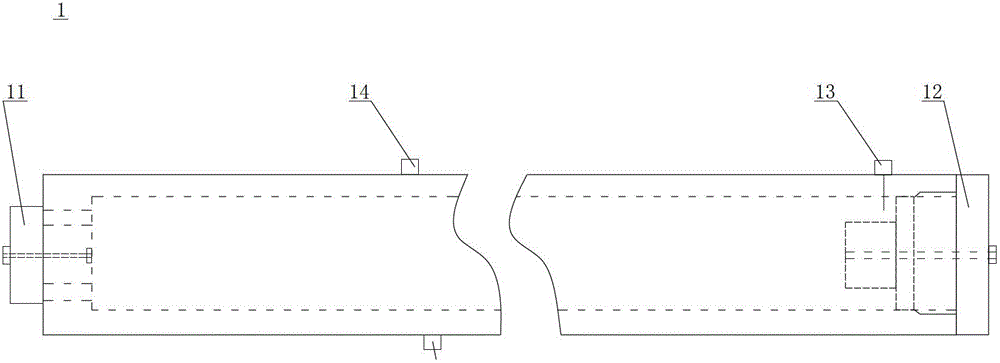

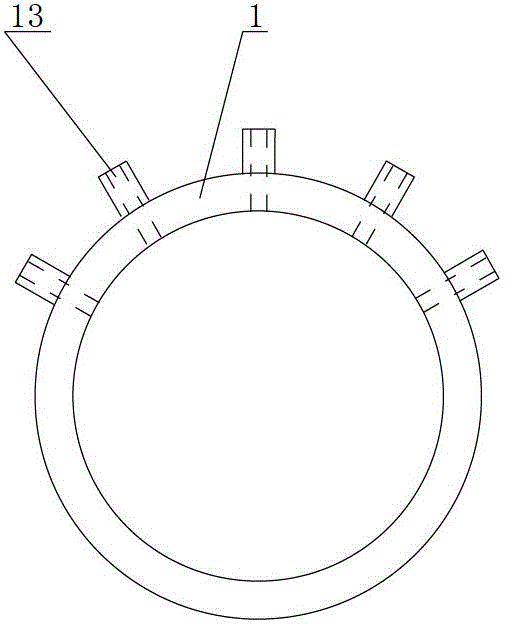

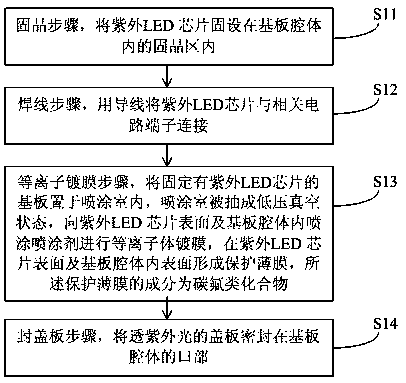

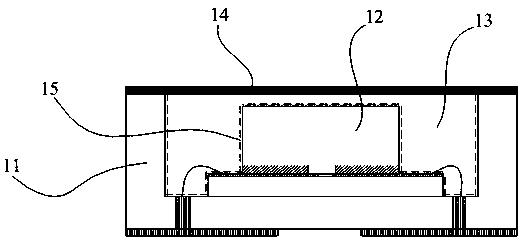

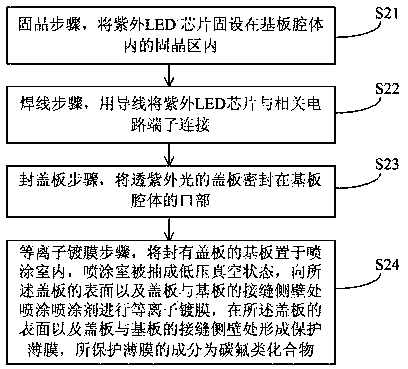

Ultraviolet LED encapsulation method

ActiveCN106531858ADelay agingLong sealing timeSolid-state devicesSemiconductor devicesChemistryPlasma coating

Owner:QINGDAO JASON ELECTRIC

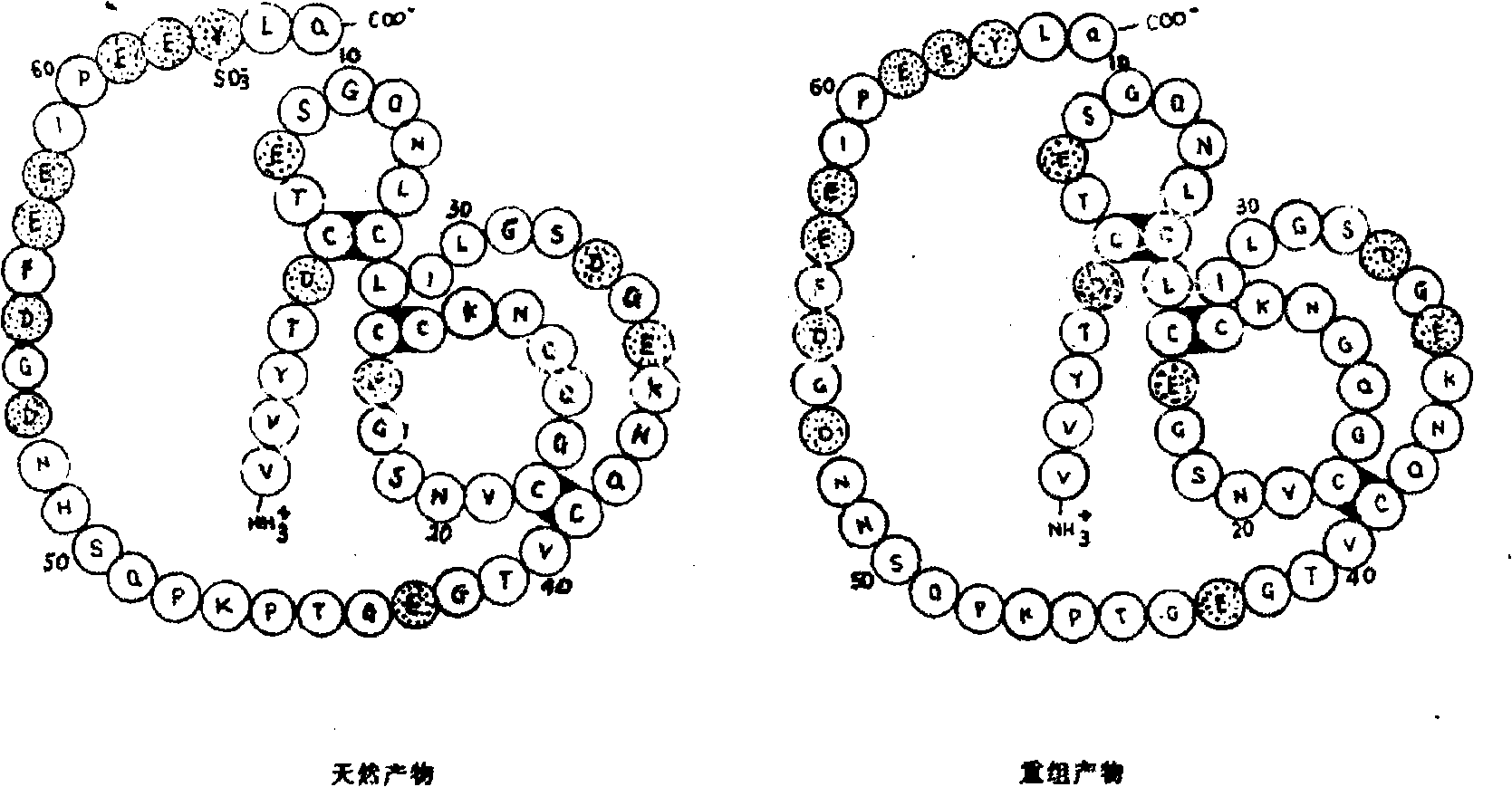

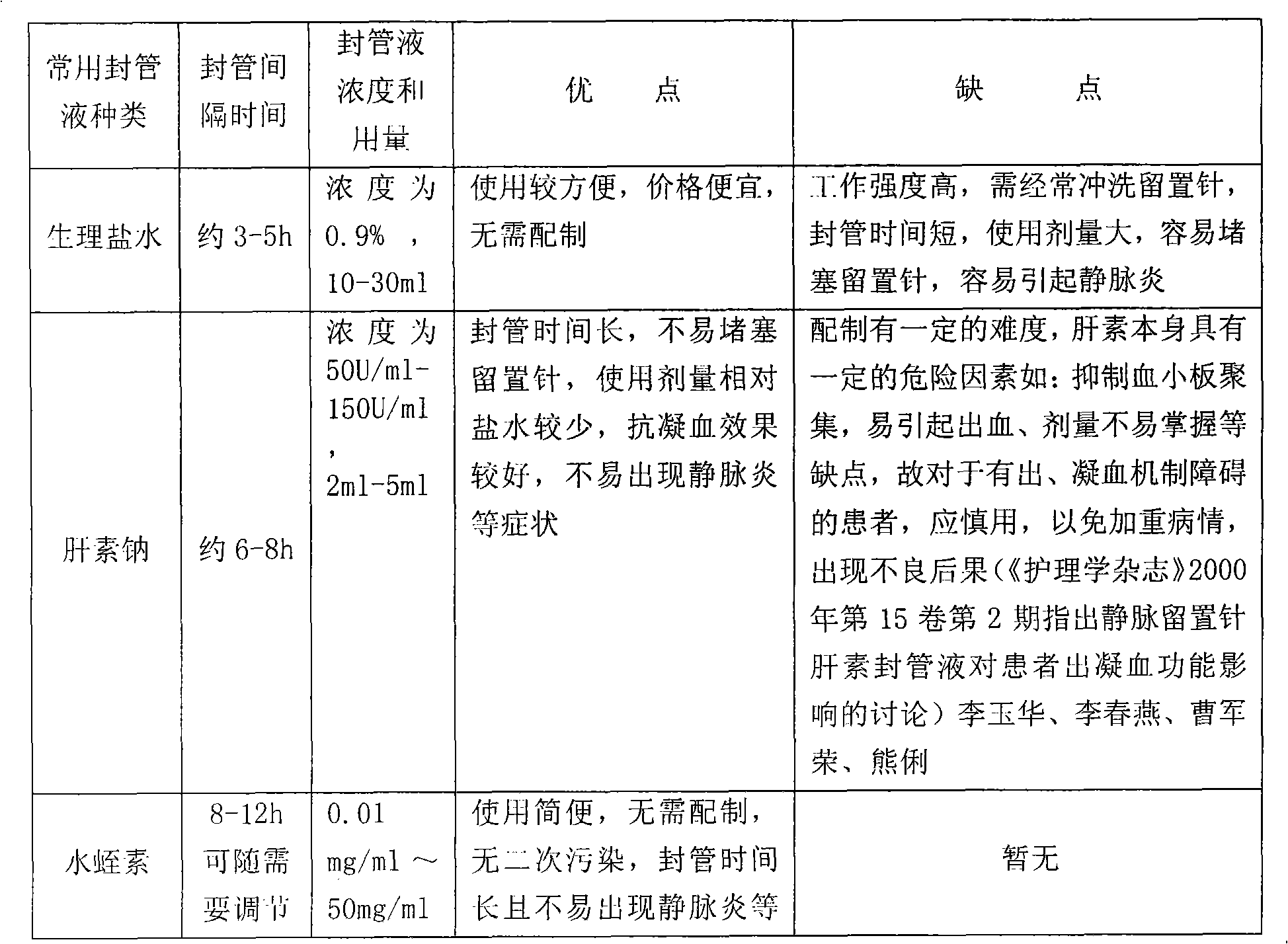

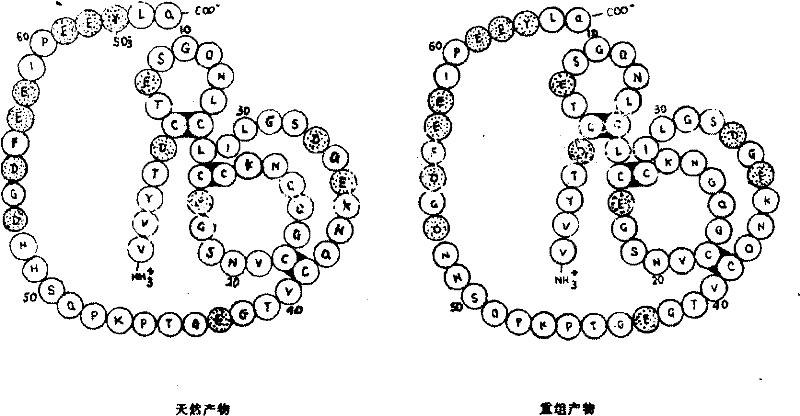

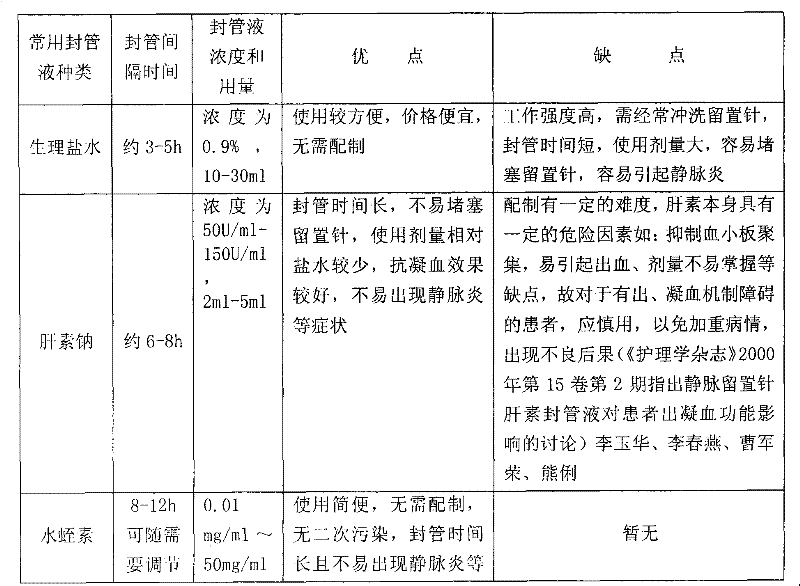

Venous retention needle suite with hirudin anticoagulation tube sealing device

InactiveCN102068731AGood anticoagulant effectReduce workloadSurgeryDiagnostic recording/measuringVeinInsertion stent

The invention provides a venous retention needle suite with a hirudin anticoagulation tube sealing device, which comprises a casing, a transparent tee joint and a transfusion joint, wherein the casing is guided by a puncture needle and inserted into a vein; the transparent tee joint is connected to a built-in isolated sealing plug at the rear end of the casing; the transfusion joint is connected with a transfusion tube or a blood taking tube; the transparent tee joint is connected with the transfusion joint by an extension tube; the transfusion joint is sealed by a sealed end cap; one end of the transparent tee joint connected with the extension tube forms a double-cavity joint; one end of the double-cavity joint is connected with the extension tube, and the other end of the double-cavity joint is connected with a tube sealing device; and the tube sealing device comprises a liquid storing bag in a support and a roller which is arranged between the two side walls of the support and used for pushing the liquid in the liquid storing bag forwards. The venous retention needle suite with the hirudin anticoagulation tube sealing device can ensure that a tubular cavity of the retention needle is filled with the tube sealing liquid. The tube sealing liquid in the tube sealing device is hirudin diluent which has good anticoagulation effect and does not influence any index of serum test in blood.

Owner:天津百新生物技术研发有限公司

Novel deodorization floor drain core

InactiveCN104727433ANot easy to breedNo standing waterSewerage structuresArchitectural engineeringEngineering

The invention discloses a novel deodorization floor drain core. The novel deodorization floor drain core comprises an upper cover plate, a filter net and a core tube, wherein the upper side of the upper cover plate is sleeved with the filter net, the core tube is arranged below the filter net, an upper thread is arranged at the upper end of the outer side of the core tube, the lower end of the outer side of the core tube is provided with a lower thread, the core tube is connected with the upper cover plate through the upper thread, a press angle is arranged on the periphery of the inner diameter of the upper end of the core tube, an upper filter core, an upper inner core tube, a lower filter core and a lower inner core tube are arranged on the lower side of the press angle in sequence, an inner press foot is arranged on the periphery of the inner diameter on the lower end of the upper inner core tube, an outer thread is arranged on the outer diameter of the lower end of the lower inner core tube, the upper filter core is jacked against the lower side of the press angle by the upper inner core tube, the lower filter core is jacked against the lower side of the inner press foot by the lower inner core tube, the lower inner core tube is connected with the core tube through the outer thread, supporting wings are arranged on the two sides of the upper filter core and the two sides of the lower filter core, and self closing water outlets are formed in the lower sides of the upper filter core and the lower filter core. The novel deodorization floor drain core has the advantages that the water-free sealing is achieved, the water draining speed is fast, the sealing effect is good, the service life is long, the maintenance cost is low, blocking is not prone to happen, and straight-through type water draining is achieved.

Owner:董伟

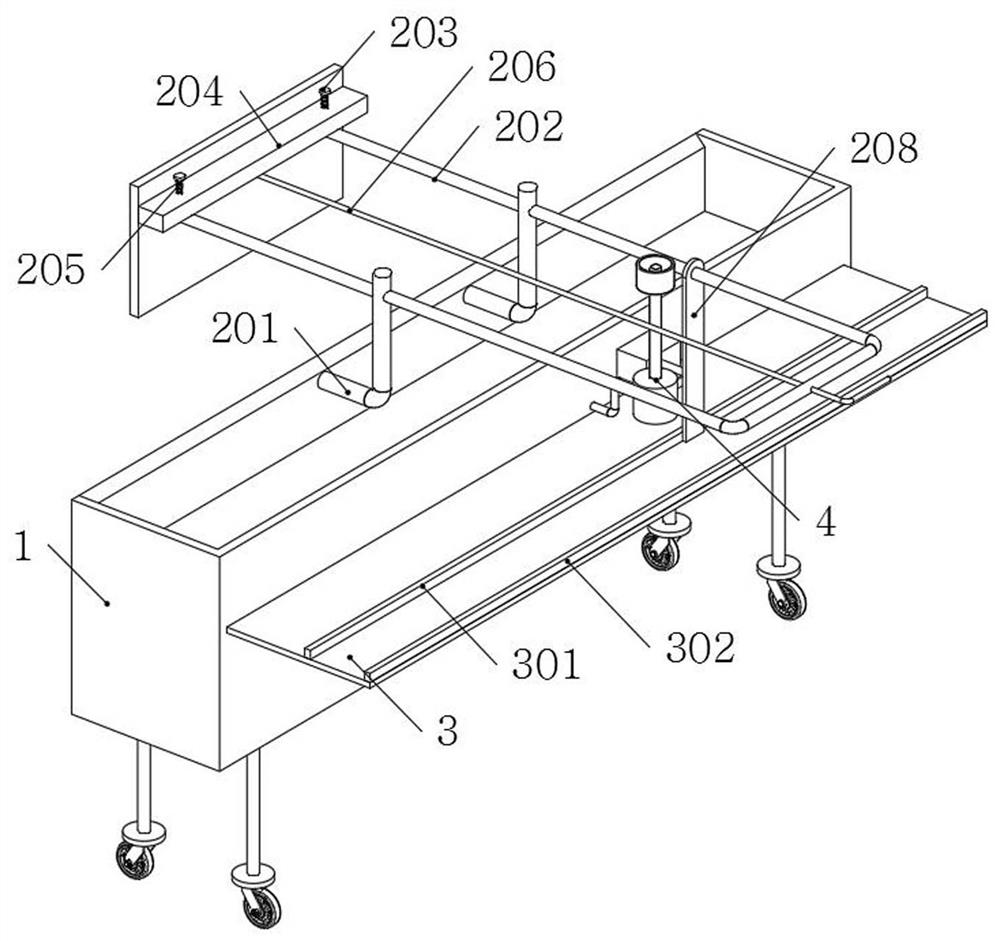

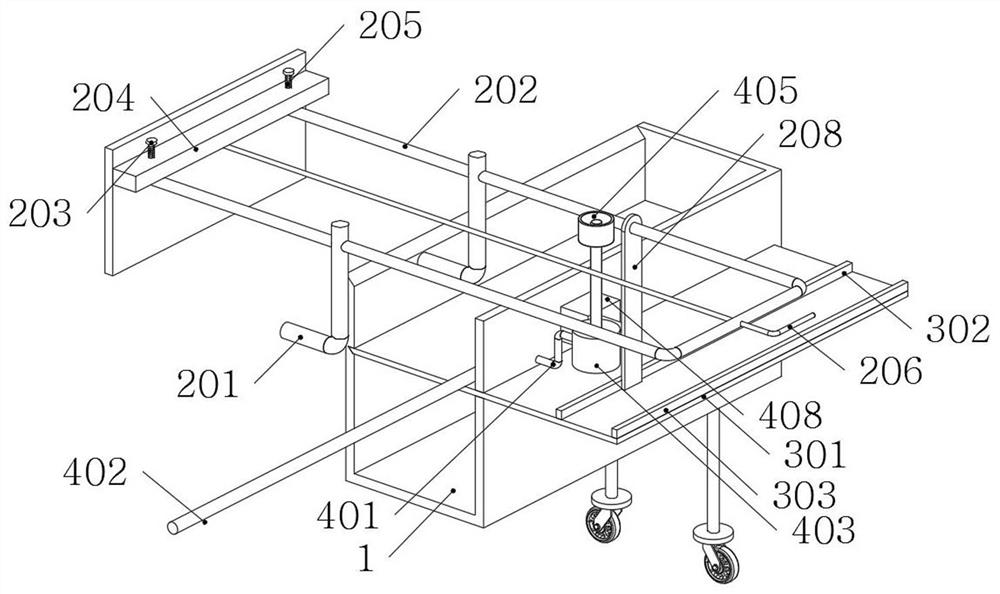

Horizontal transverse sealing station

ActiveUS20160193783A1Increase speedReduce the average velocityControlling laminationLaminationEngineeringMechanical engineering

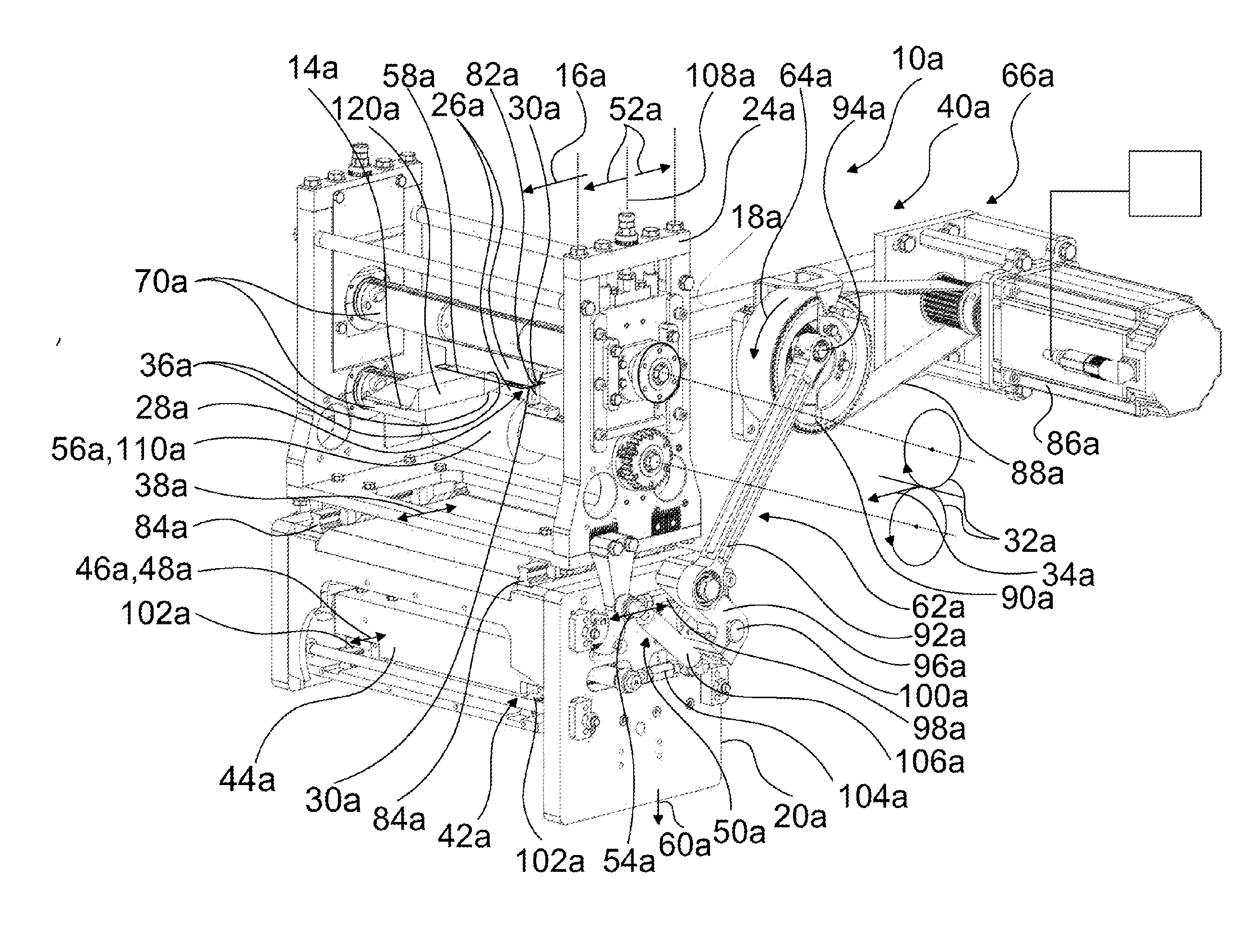

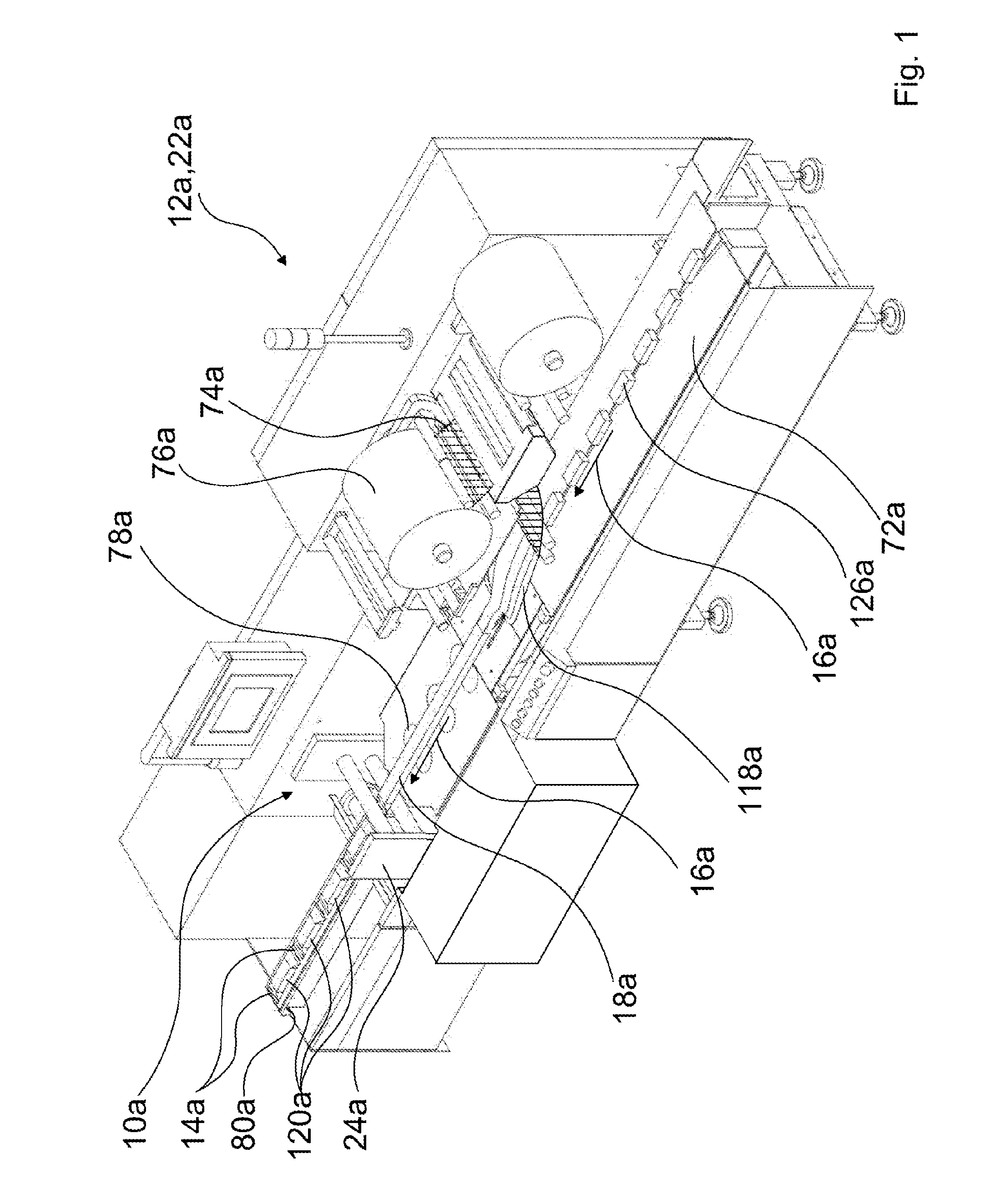

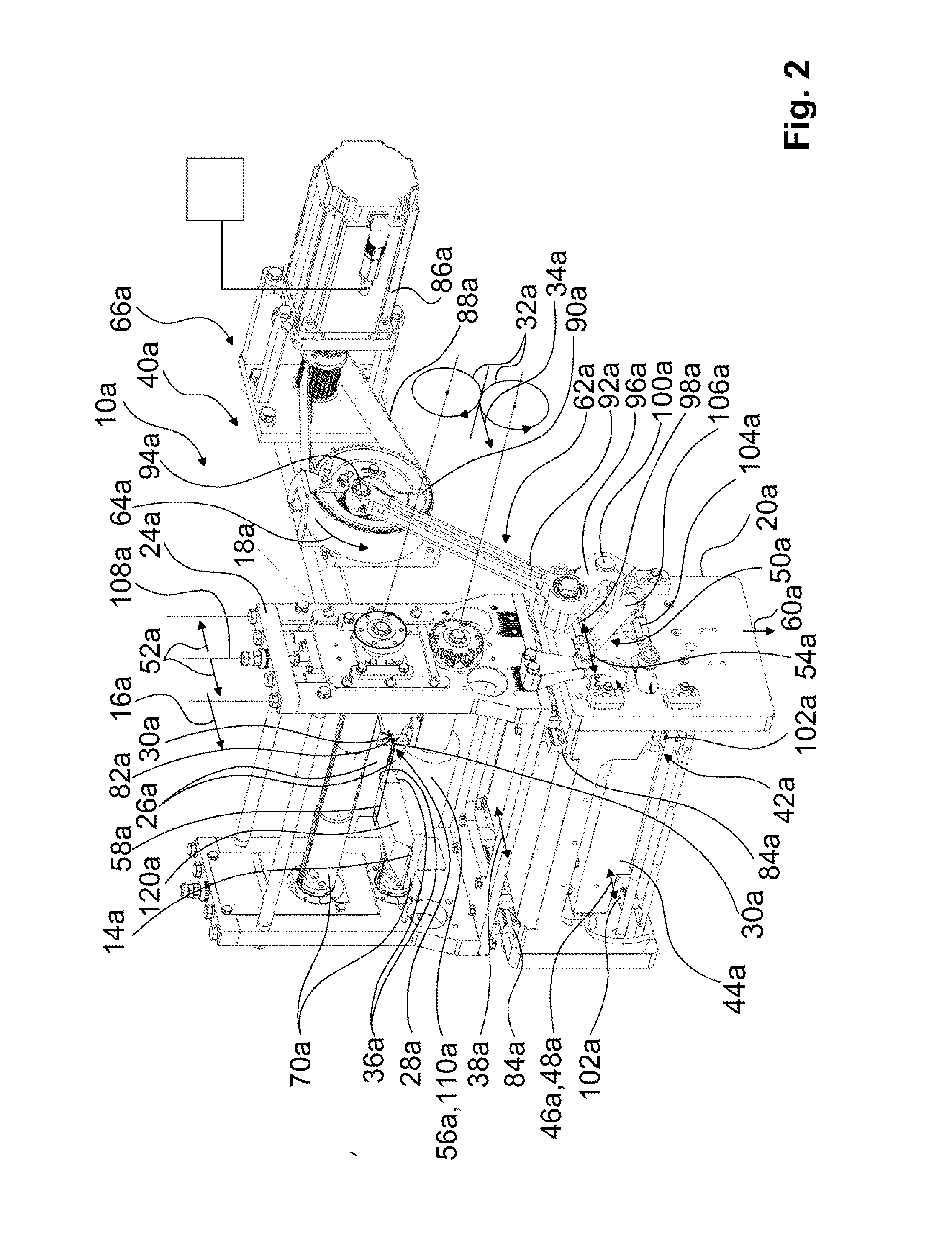

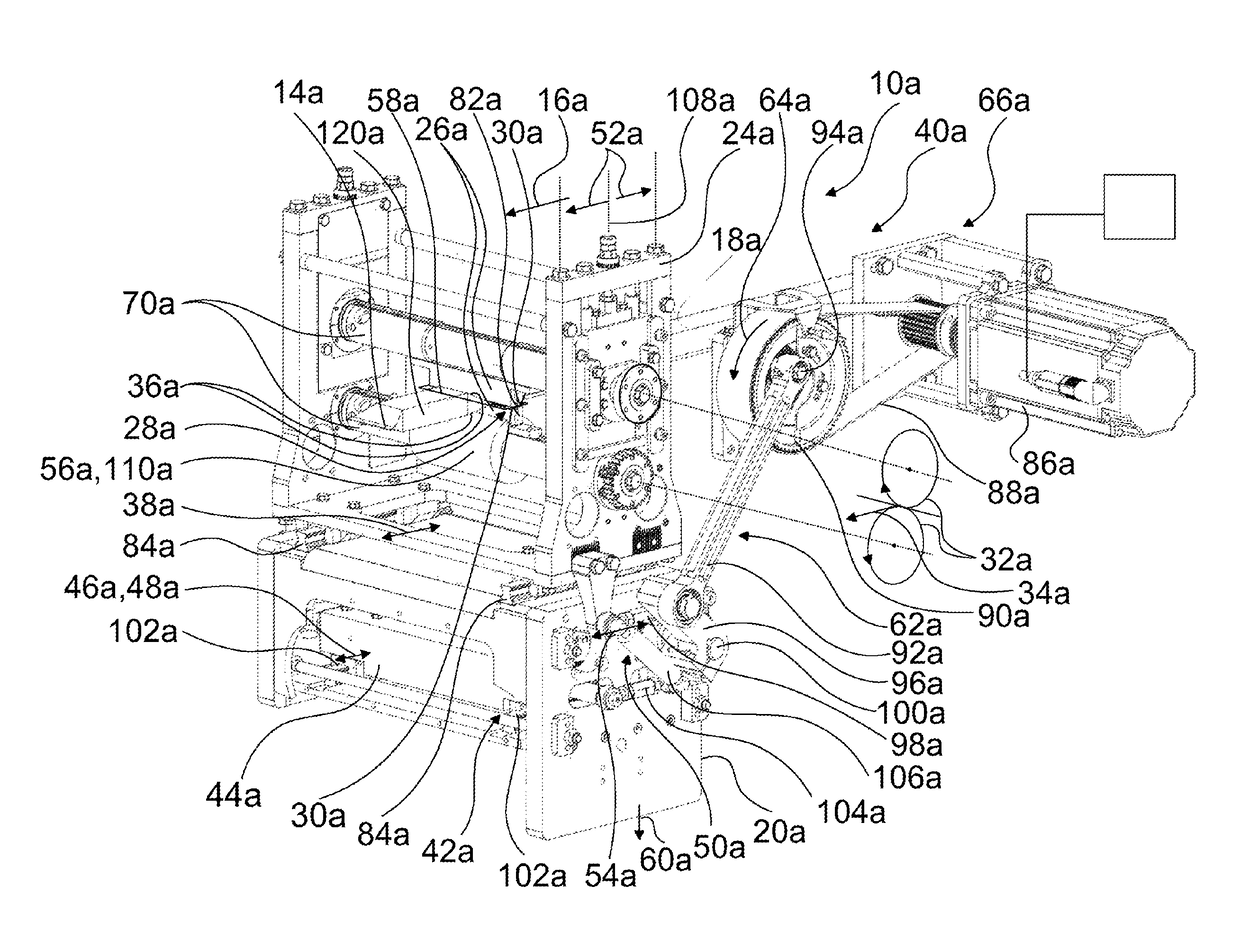

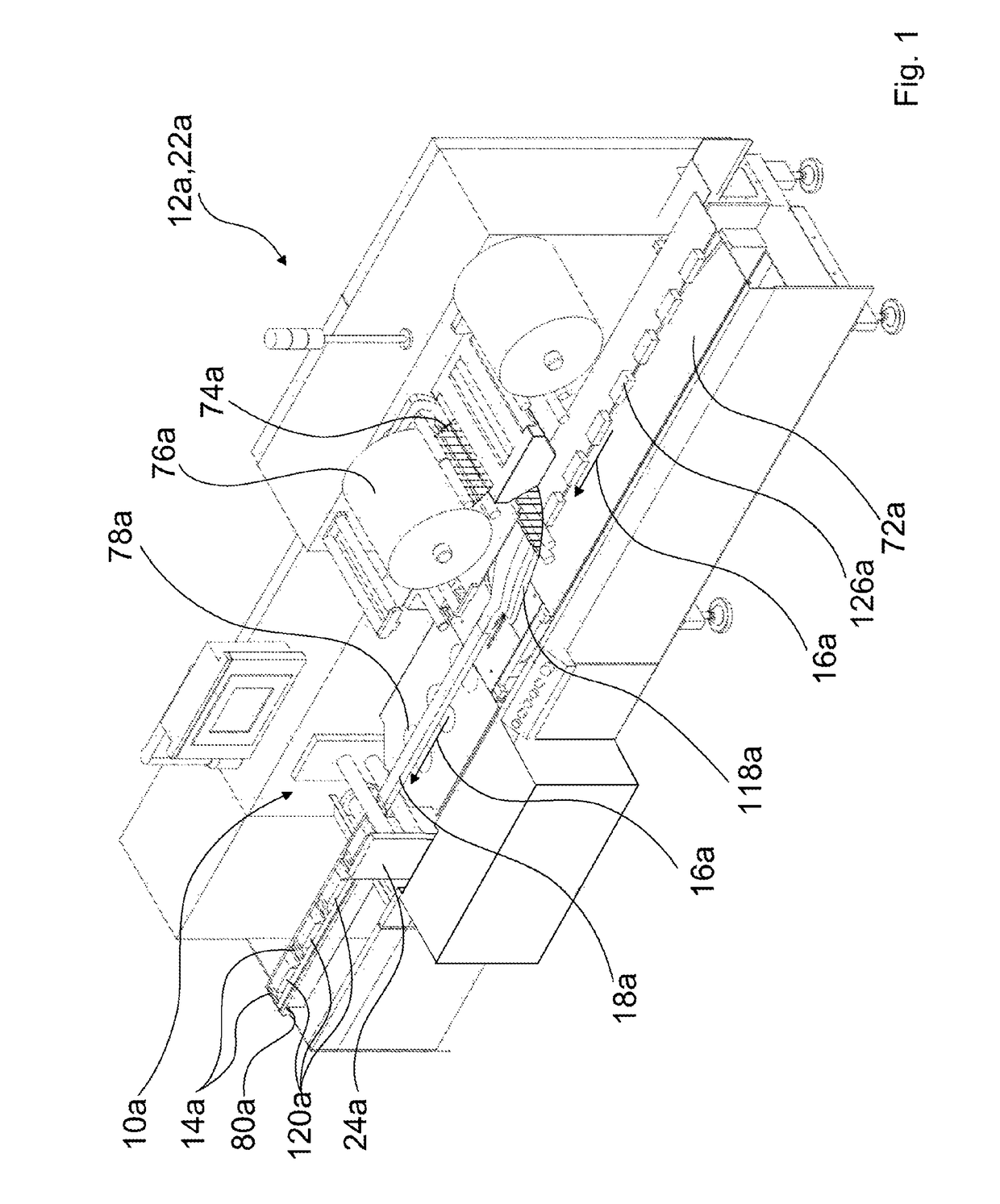

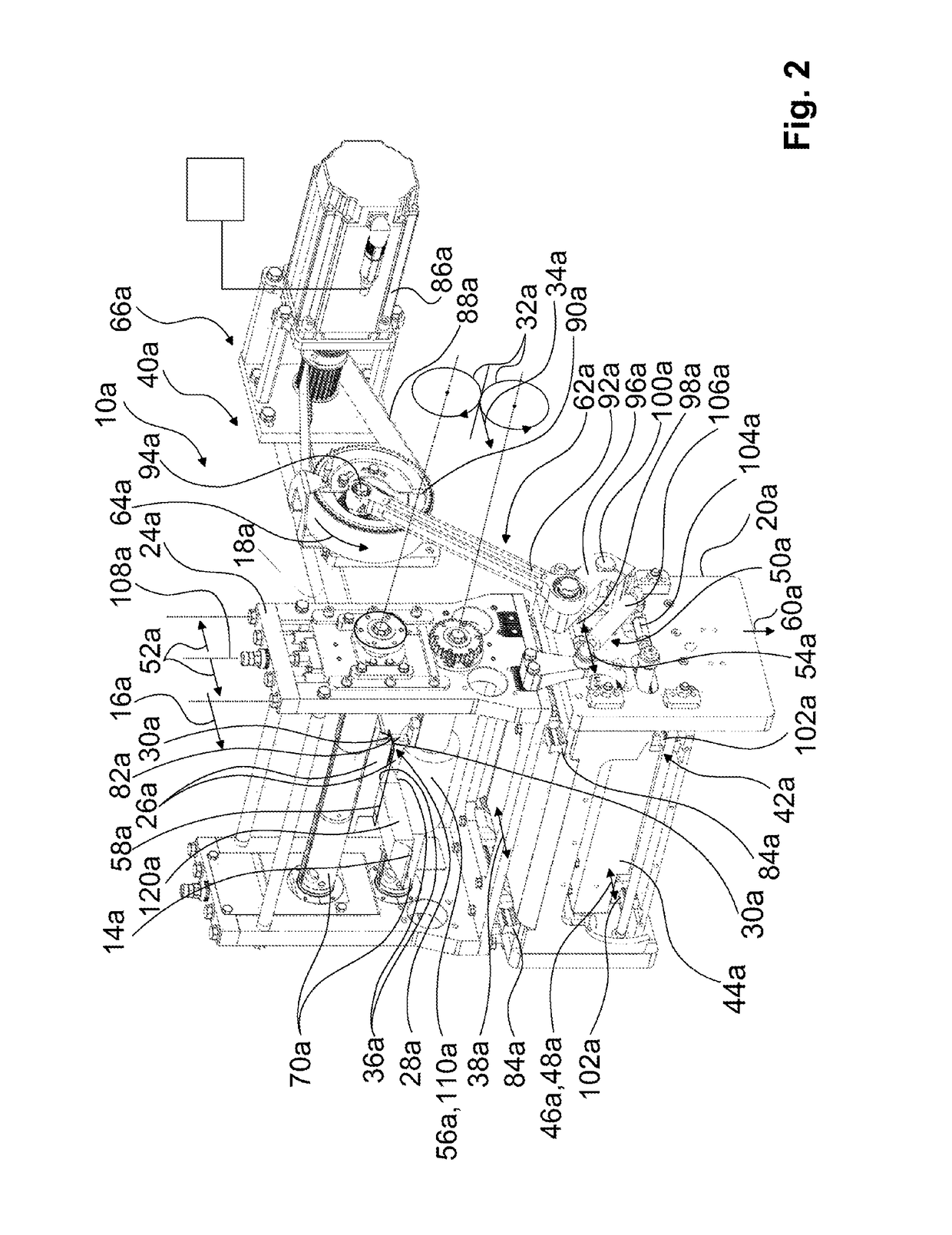

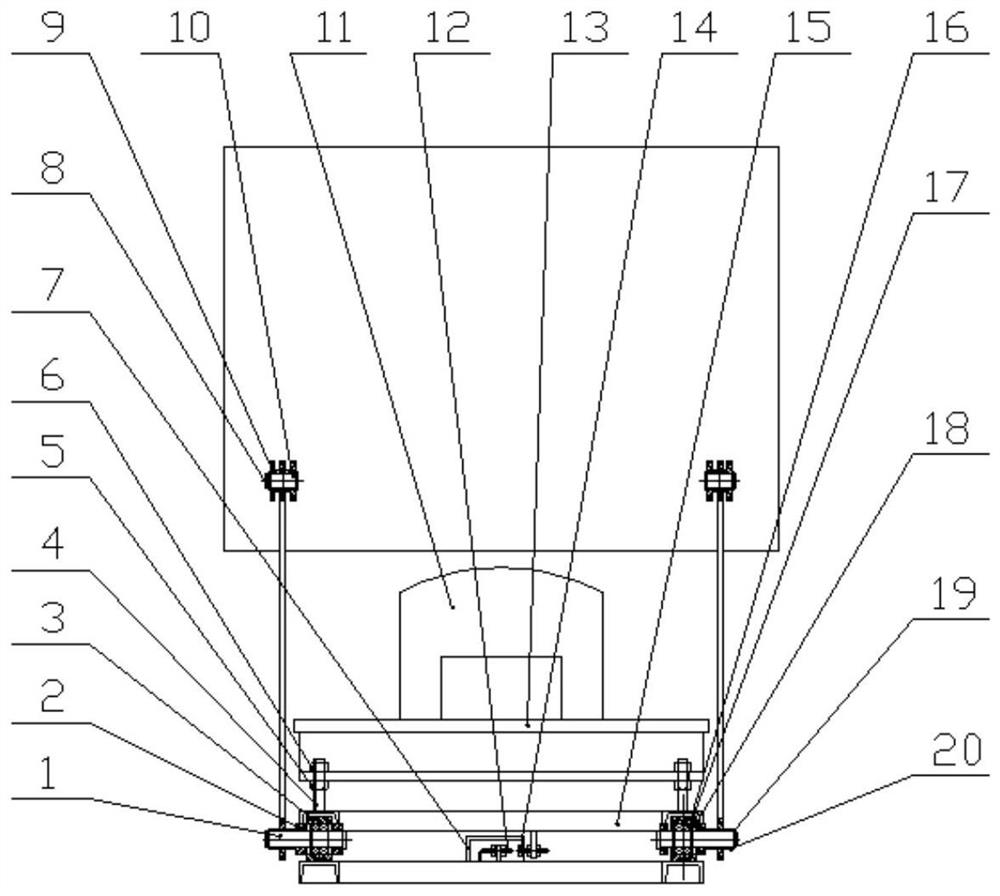

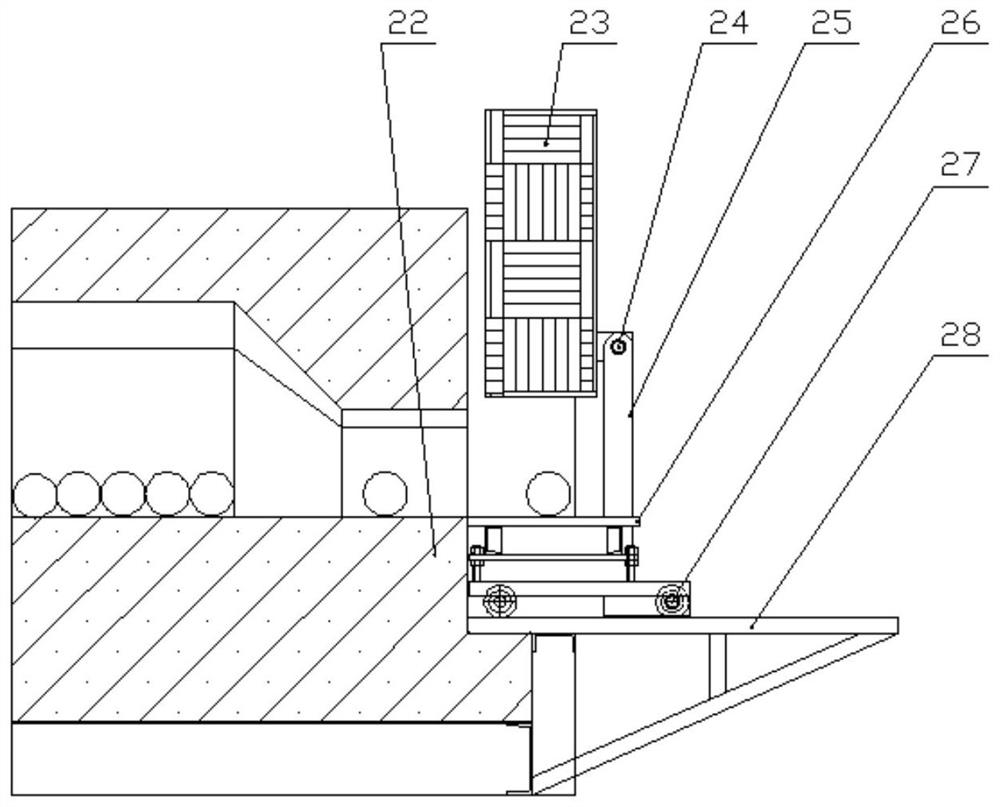

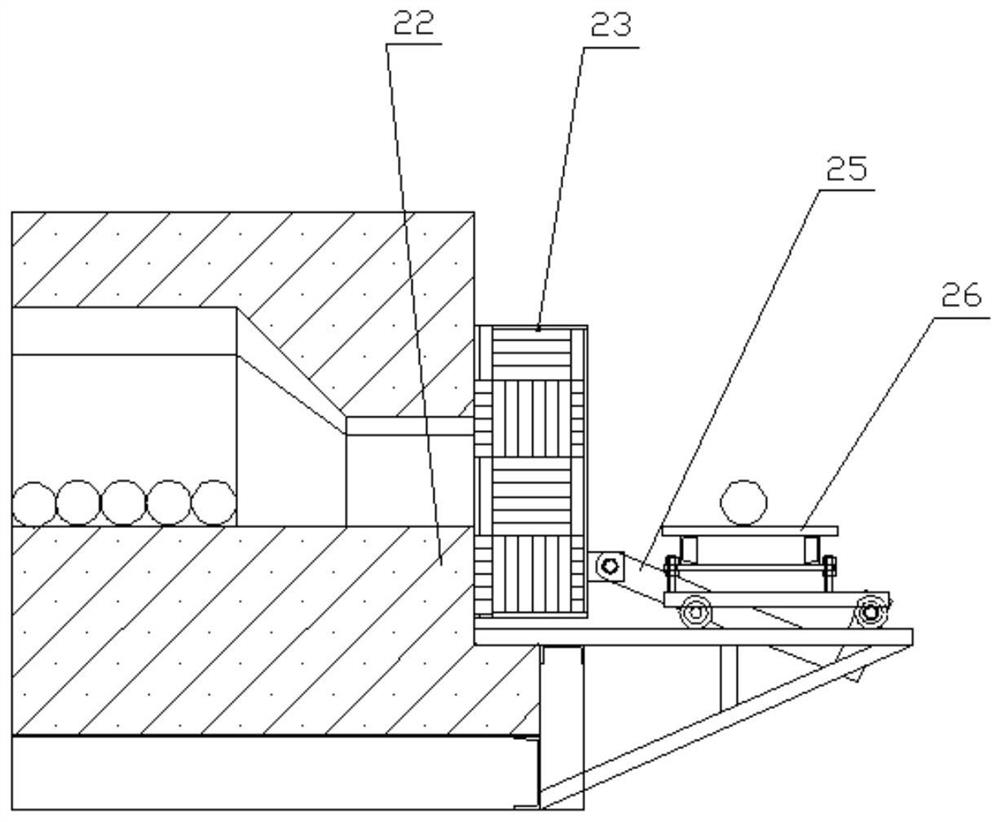

The invention relates to a horizontal transverse sealing station (10a-b), in particular for a horizontal tubular bag machine (12a-b), for producing transverse sealing seams (14a-b) on at least one film tube (18a-b) transported in a continuous, at least essentially horizontal transport direction (16a-b), comprising a transverse sealing station base (20a-b) fixedly connected to a packing machine (22a-b), a transverse sealing unit (24a-b), and at least one sealing jaw pair (28a-b) movably mounted on the transverse sealing unit (24a-b) and formed by two sealing jaws (26a-b), the sealing surfaces (30a-b) of which come closer to each other during a sealing process in a sealing movement (32a-b), which relative to the transverse sealing unit (24a-b) is provided with at least one movement component (34a-b) in the transport direction (16a-b), in order to seal material layers (36a-b) of the film tube (18a-b) between the sealing surfaces (30a-b) by way of heating and / or applying pressure, and to remove again at the end of the sealing process. According to the invention the transverse sealing unit (24a-b) is driveably mounted on the transverse sealing station base (20a-b) in a displacement movement (38a-b) that is at least substantially parallel to the transport direction (16a-b).

Owner:SYNTEGON PACKAGING SYST AG

Hirudin anticoagulation tube sealing device for venous retention needle

InactiveCN102120051AGood anticoagulant effectReduce workloadDiagnostic recording/measuringSensorsMedicineSyringe needle

The invention discloses a hirudin anticoagulation tube sealing device for a venous retention needle, which comprises a sleeve, a transparent tee joint connected with the rear end of the sleeve, and a transfusion connector connected with a transfusion tube or a blood collecting tube; a connecting part connected with a tube sealing injector is arranged on the middle section of an extension tube; the tube sealing injector comprises a liquid tube in which a tube cavity is formed, a needle part connected with the front end of a sealed tube, and a shell which is sleeved outside the liquid tube and of which the rear end is sealed; a raised clamping wire is formed on the outer surrounding wall of the rear end of the liquid tube; a clamping groove is formed on the inner surrounding wall of the front end of the shell, and clamping steps at equal distance intervals are formed on the inner surrounding wall of the shell; and a sealing plug connected with the rear wall of the shell is arranged in the liquid tube. The hirudin anticoagulation tube sealing device for the venous retention needle can ensure the same amount of tube sealing liquid can be pushed in at each time and the tube sealing liquid can fully fill the tube cavity of the retention needle. The tube sealing liquid in the tube sealing injector is dilute solution of hirudin which has high anticoagulation effect and does not influence the test of the indexes of the serum in blood.

Owner:天津百新生物技术研发有限公司

Horizontal transverse sealing station

ActiveUS9649810B2Increase speedCompensation differenceLaminationLamination apparatusMechanical engineeringEngineering

The invention relates to a horizontal transverse sealing station (10a-b), in particular for a horizontal tubular bag machine (12a-b), for producing transverse sealing seams (14a-b) on at least one film tube (18a-b) transported in a continuous, at least essentially horizontal transport direction (16a-b), comprising a transverse sealing station base (20a-b) fixedly connected to a packing machine (22a-b), a transverse sealing unit (24a-b), and at least one sealing jaw pair (28a-b) movably mounted on the transverse sealing unit (24a-b) and formed by two sealing jaws (26a-b), the sealing surfaces (30a-b) of which come closer to each other during a sealing process in a sealing movement (32a-b), which relative to the transverse sealing unit (24a-b) is provided with at least one movement component (34a-b) in the transport direction (16a-b), in order to seal material layers (36a-b) of the film tube (18a-b) between the sealing surfaces (30a-b) by way of heating and / or applying pressure, and to remove again at the end of the sealing process. According to the invention the transverse sealing unit (24a-b) is driveably mounted on the transverse sealing station base (20a-b) in a displacement movement (38a-b) that is at least substantially parallel to the transport direction (16a-b).

Owner:SYNTEGON PACKAGING SYST AG

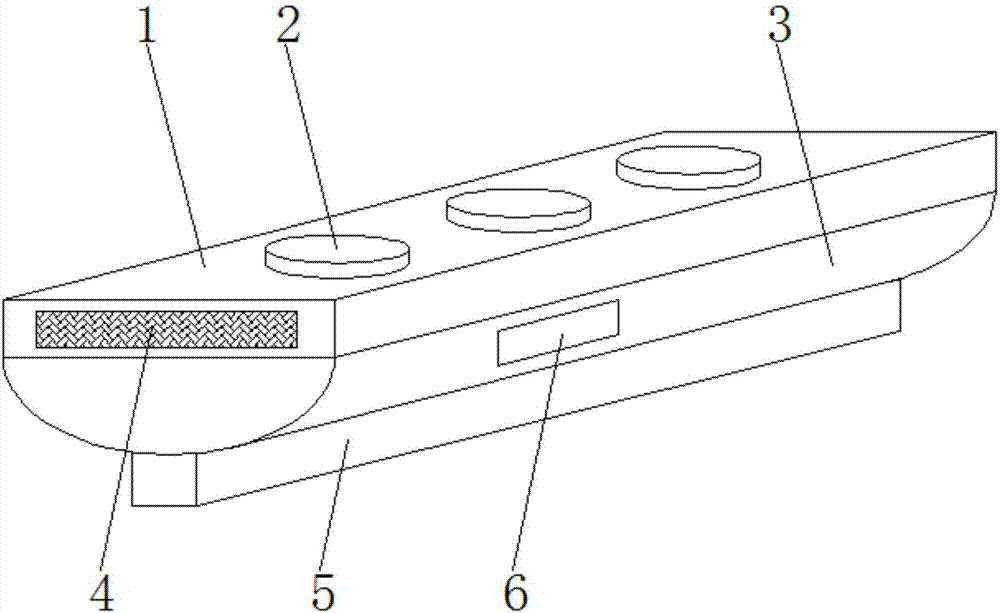

Air purifying device for passenger car

PendingCN107351652AGood purification effectImprove efficiencyHuman health protectionAir-treating devicesActivated carbonL-shell

The invention discloses an air purifying device for a passenger car. The air purifying device comprises an upper shell, a lower shell, an air detection instrument and an activated carbon adsorption filter screen. Sucking discs are fixed to the upper end of the upper shell, and air outlets are formed in the two sides of the upper shell and connected with an exhaust opening of a fan through exhaust pipes; the fan is installed inside the upper shell; the air detection instrument is installed on the outer wall of the upper shell, and the upper shell is connected with the lower shell through buckles; a controller is installed on the outer wall of the lower shell and electrically connected with the air detection instrument through a wire; an air inlet is formed in the lower end of the lower shell, and an HEPA and an initial effect filter screen are sequentially installed inside the air inlet from top to bottom; and a static filter screen, a cold catalyst filter screen and the activated carbon adsorption filter screen are sequentially installed inside the lower shell from top to bottom, and an ultraviolet germicidal lamp is installed on the inner wall of the lower shell. The air quality in the car is detected through the air detection instrument, the air in the car is sucked in and purified through the fan, the purifying efficiency is high, and using is convenient.

Owner:深圳市宇泓时代科技有限公司

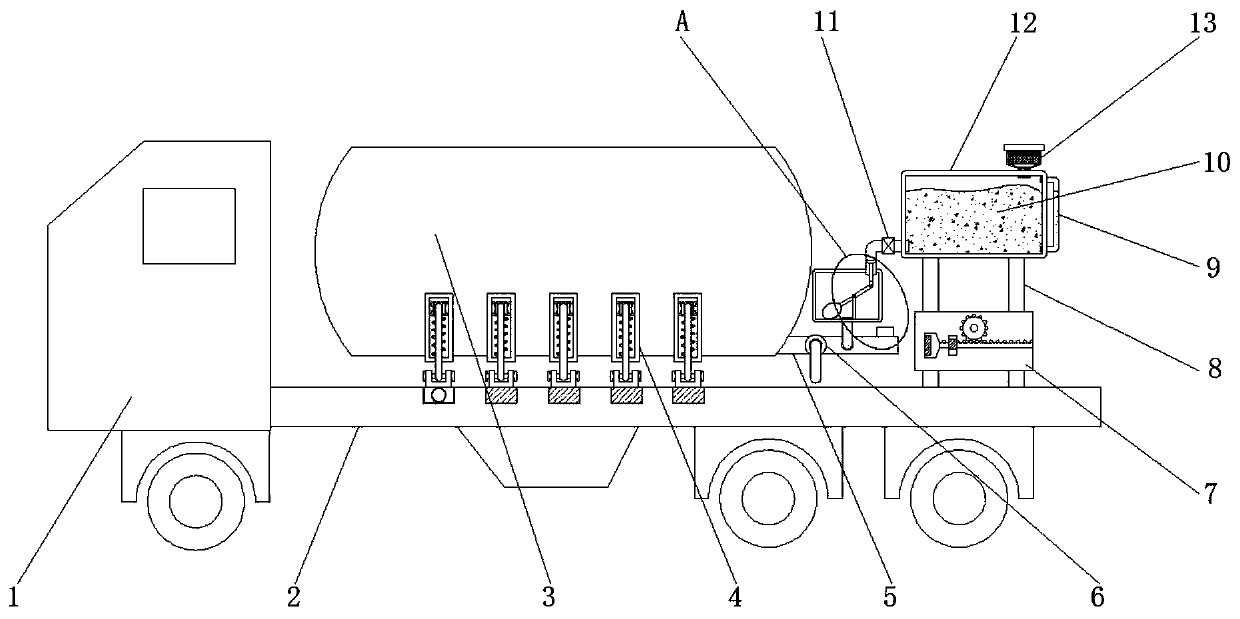

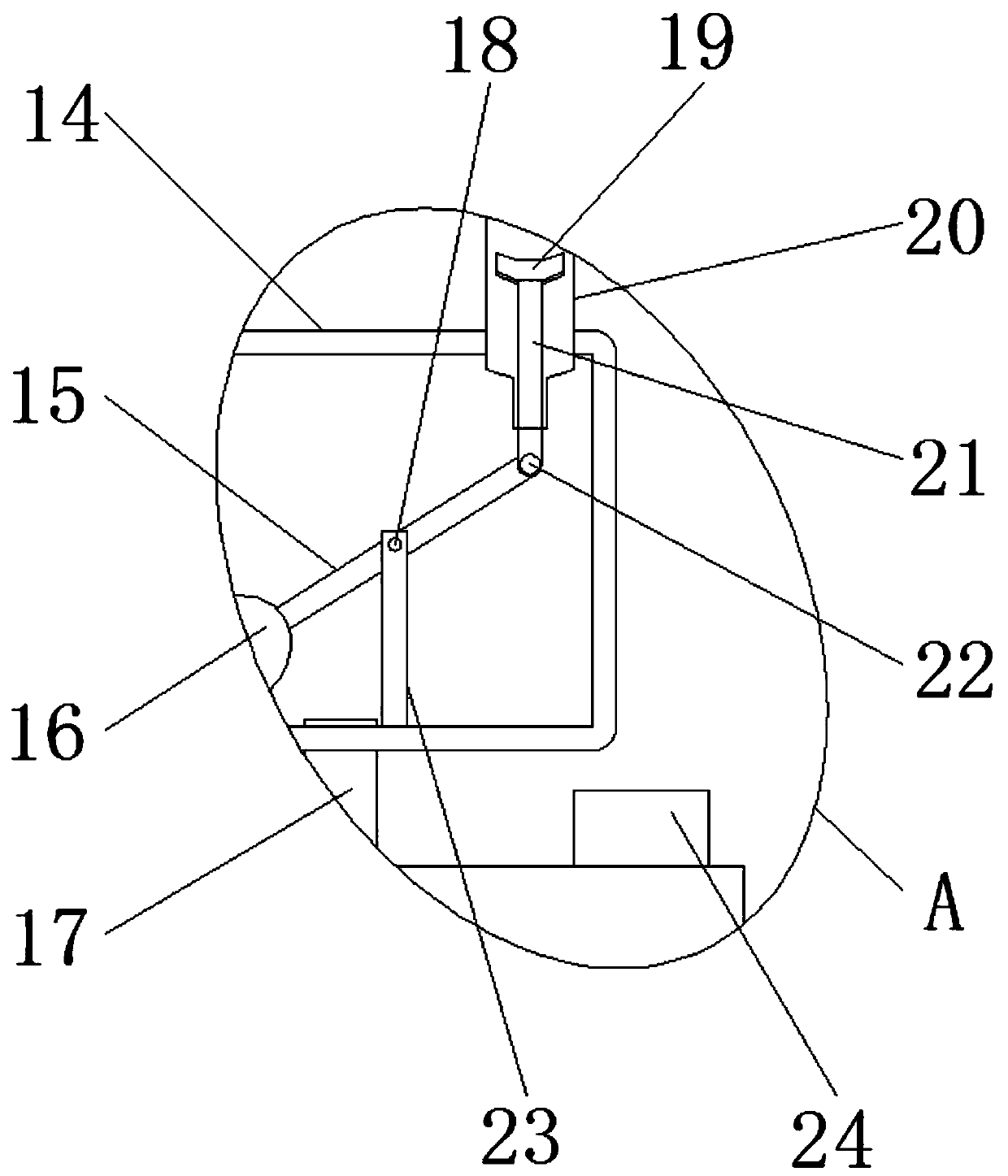

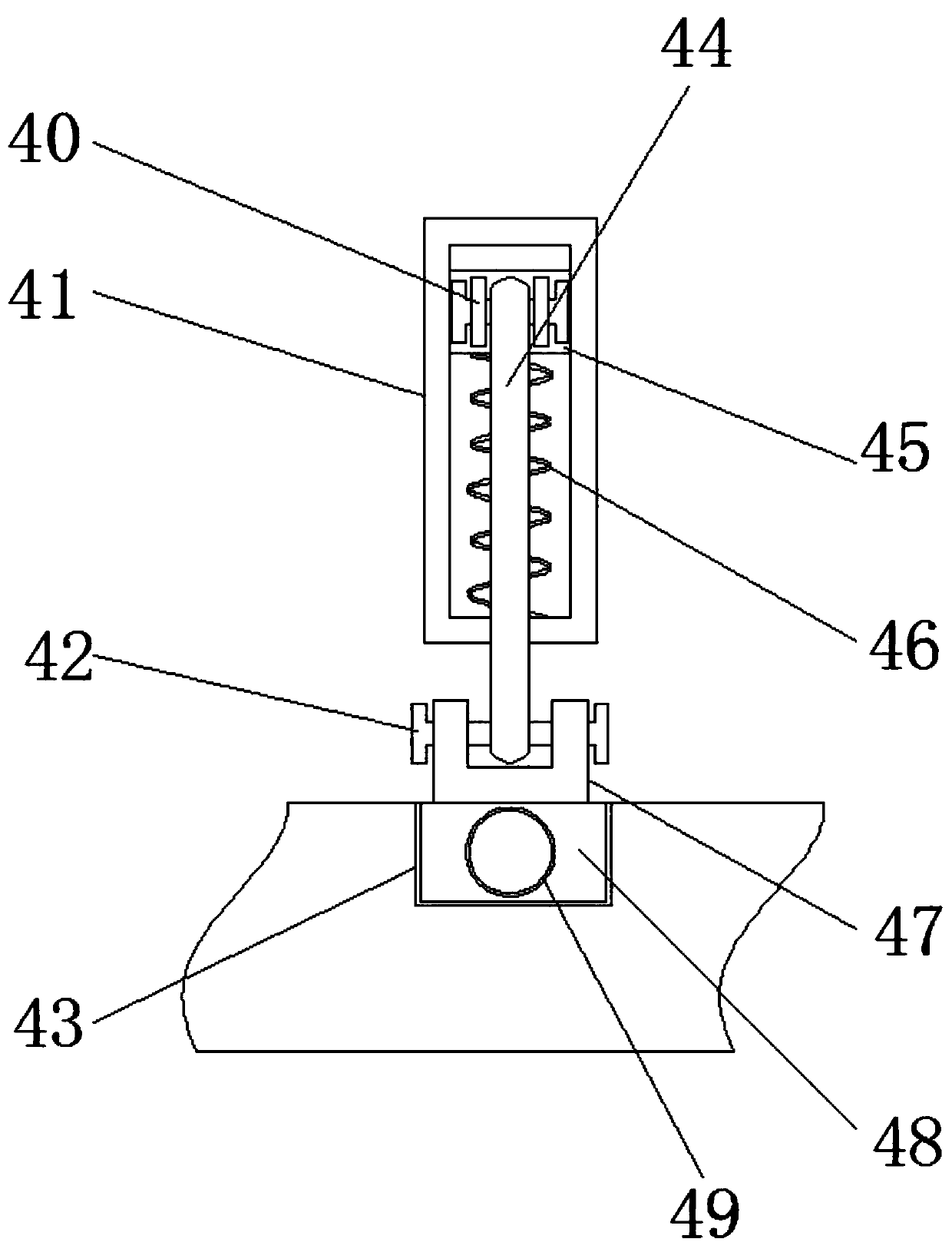

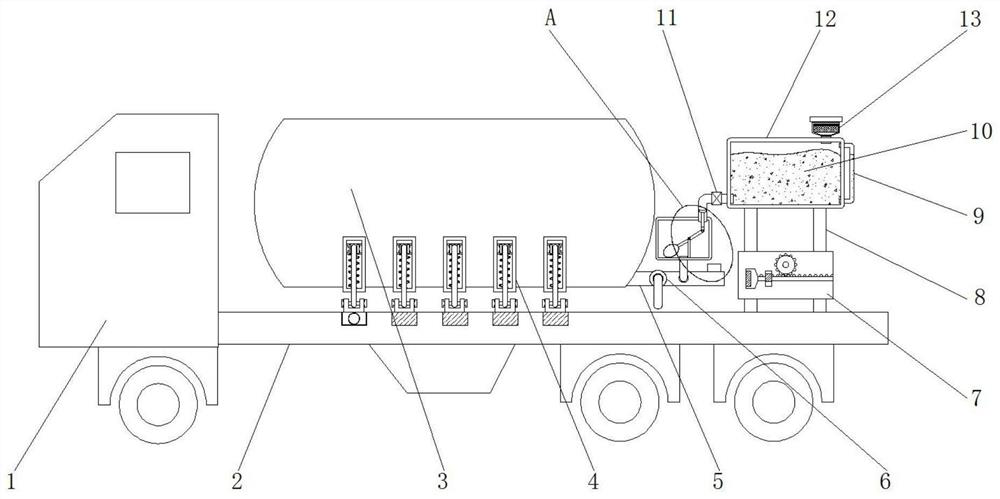

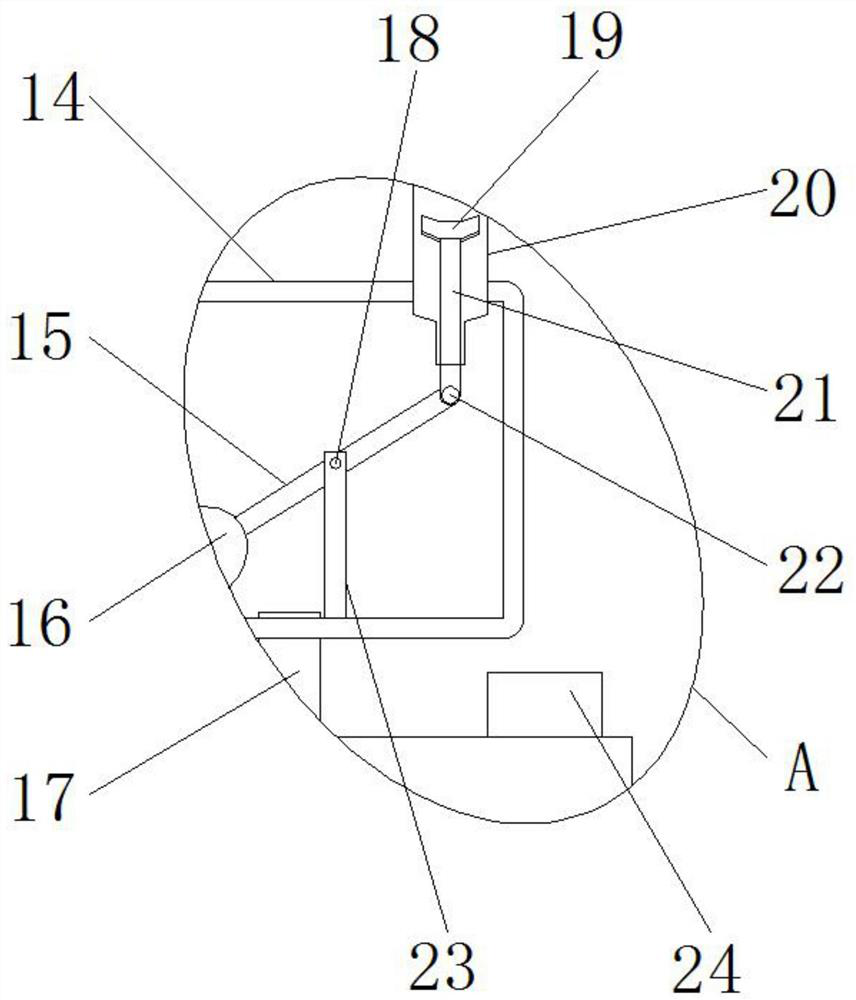

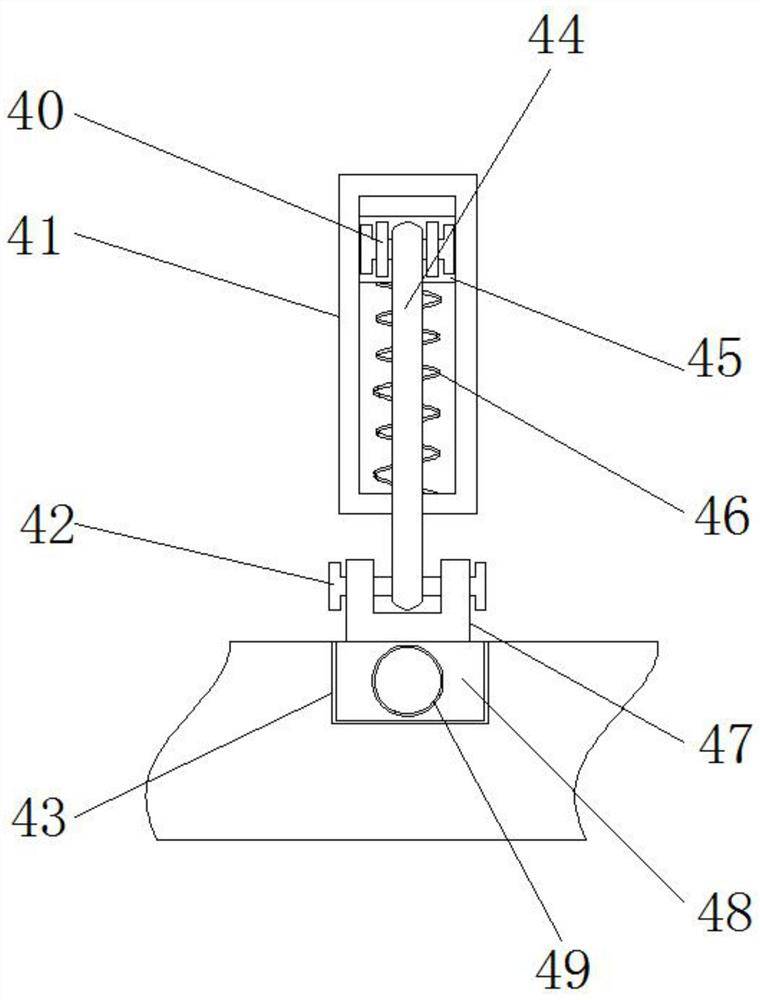

Anti-leakage natural gas closing device and using method thereof

ActiveCN111486342AImprove sealingImprove securityVessel mounting detailsVessel geometry/arrangement/sizeOil canNatural gas storage

The invention discloses an anti-leakage natural gas closing device and a using method thereof, and relates to the natural gas closing device. The natural gas closing device specifically comprises a transport vehicle, a vehicle plate and a natural gas storage tank, in the natural gas leakage process, when natural gas leaks, the natural gas is discharged from a gas outlet pipe, a gas sensor recognizes natural gas leakage, a controller controls a motor to be started firstly, after the motor is started for a period of time, through the meshing effect of a gear and a rack rod, the sealing performance is good, and the safety is improved; the air outlet pipe is blocked in a sealing oil outflow mode, the sealing oil can be automatically added in the leakage process, the sealing time is prolonged,excessive adding of the sealing oil is reduced, and resource waste is reduced; and a damping support can buffer shaking generated during transportation of the natural gas storage tank, the stability of the natural gas storage tank in the transportation process is improved, the valve deviation possibility is reduced by increasing the stability of the natural gas storage tank, and leakage possibility is prevented from increasing.

Owner:KUNSHAN ENERGY HUNAN HUANGGANG LIQUEFIED NATURAL GAS

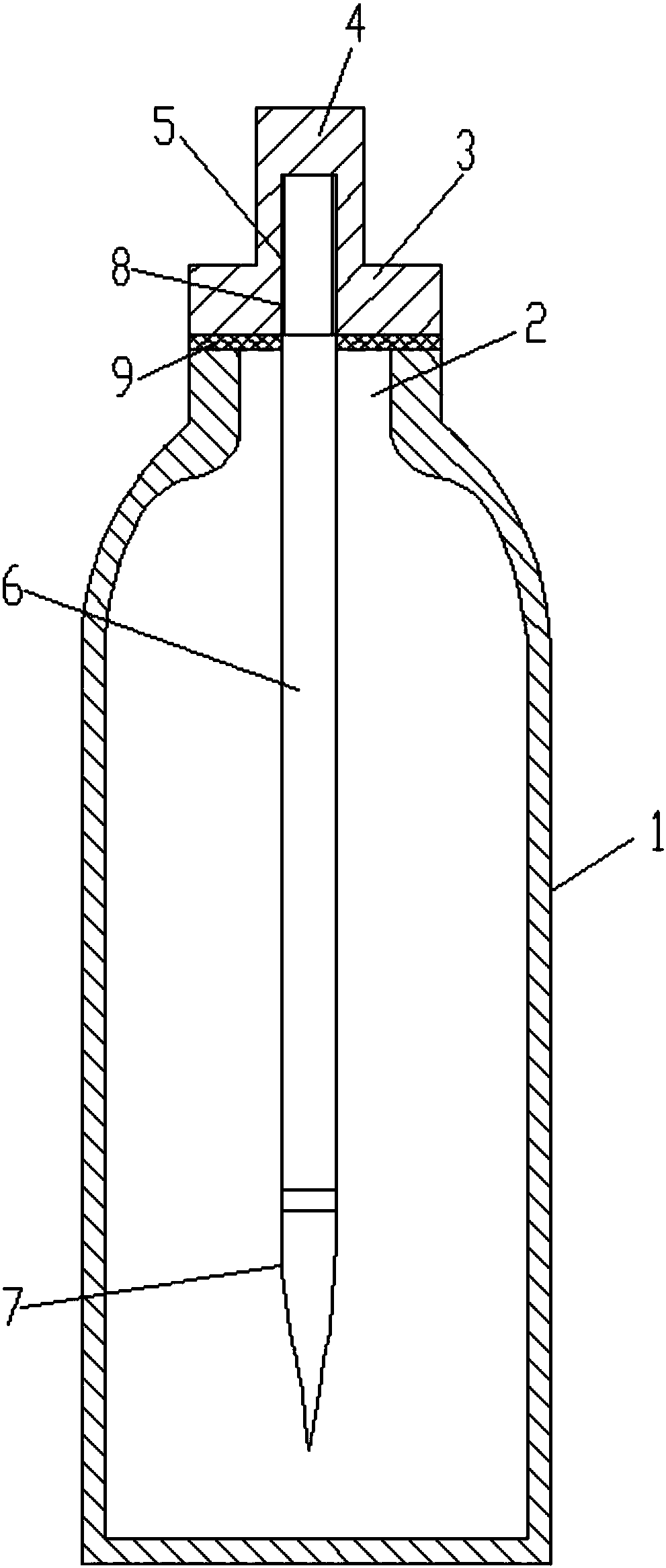

Brush no-clean moisturizing structure

The invention provides a brush no-clean and moisturizing structure. The brush no-clean and moisturizing structure includes a moisturizing bottle body, and the interior of the moisturizing bottle bodyis used for suspending a brush pen body. A moisturizing bottle opening for the brush pen body to penetrate into the inner cavity of the moisturizing bottle body is formed in the upper end of the moisturizing bottle body, a sealing supporting block for supporting the top end of the brush pen body is formed in the upper portion of the of the moisturizing bottle opening, the lower end face of the sealing supporting block is attached to the upper end face of the moisturizing bottle body in a sealing mode, and the sealing supporting block is detachably connected with the top end of the brush pen body. According to the brush no-clean and moisturizing structure, ink on a pen point of the brush pen body can be effectively prevented from vaporizing and killing, the brittle phenomenon caused by hardening of the pen point of a brush pen is avoided, and the cleaning step after each use of the brush pen is avoided, and damage to the brush point of the brush pen is reduced; and the service lift of the brush pen is prolonged, the time of cleaning the brush pen by people is saved, and good moisturizing seal performance is achieved.

Owner:贺俞童

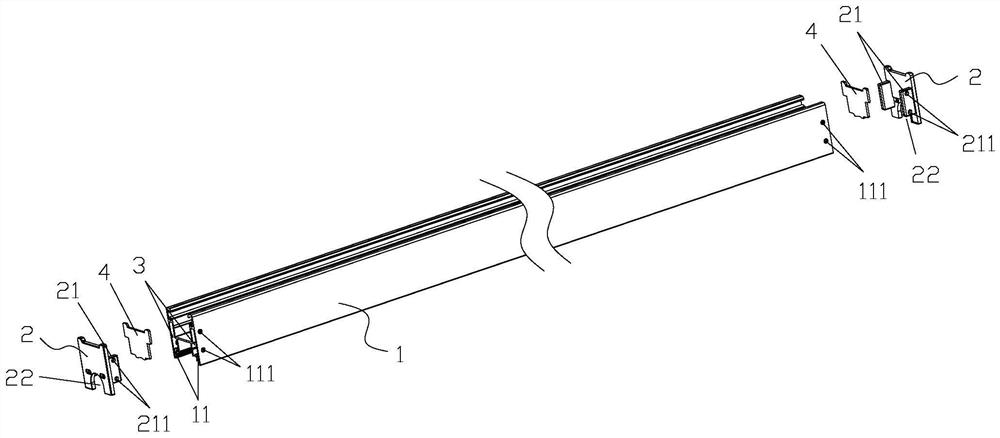

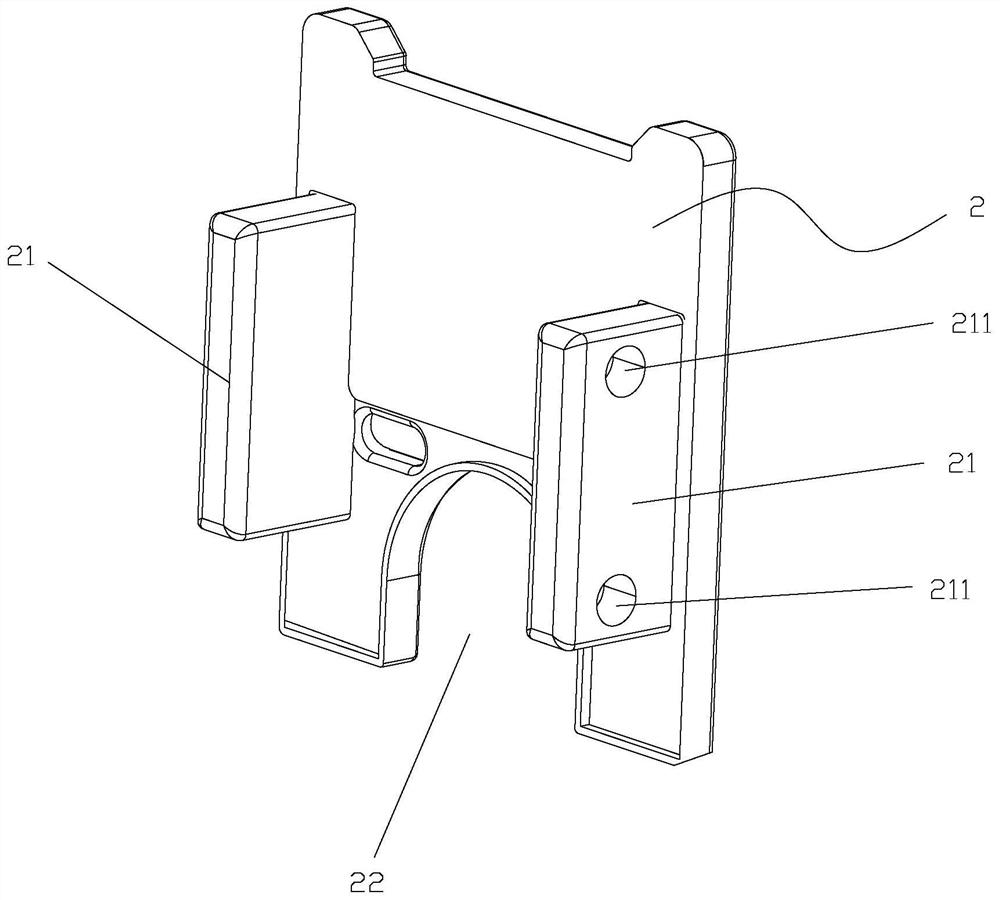

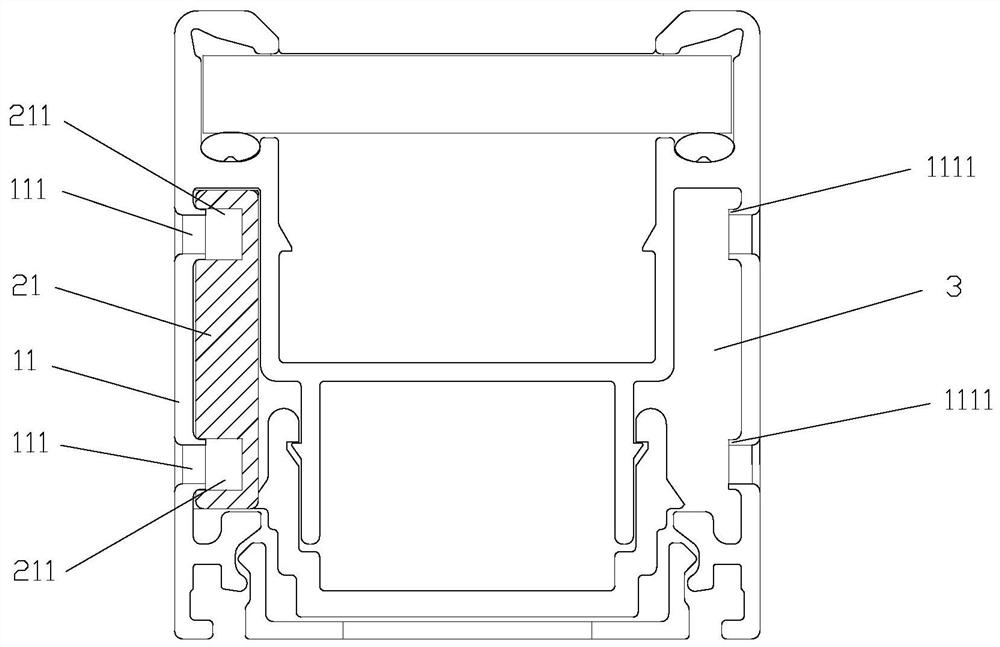

Lamp body with end covers free of screw installation and waterproof wall washing lamp

PendingCN112815275AAchieve fixationEasy to automate installationMechanical apparatusElectric circuit arrangementsEngineeringStructural engineering

The invention discloses a lamp body with end covers free of screw installation. The lamp body comprises a lamp body profile and the two end covers. The lamp body profile comprises two flat plates which are oppositely arranged, wherein inserting grooves are formed in the inner side faces of the two flat plates, two inserting blocks which are correspondingly inserted into the two inserting grooves are arranged on the inner side faces of the end covers, circular riveting grooves are formed in the inserting blocks, riveting hole positions are formed in the positions, corresponding to the circular riveting grooves, of the riveted flat plates in a riveted mode, and convex ring parts which tightly press the inner walls of the circular riveting grooves are formed at the inner ends of the wall surfaces of the riveting hole positions. The invention further discloses a waterproof wall washing lamp. The waterproof wall washing lamp comprises the lamp body with the end covers free of screw installation, wherein wing plates and waterproof plates are arranged on two flat plates in an up-down separated and opposite extending mode, arc-shaped grooves with protruding ribs are formed in the waterproof plates, hollow silica gel strips are arranged in the arc-shaped grooves, and a glass plate is arranged between the two wing plates and the two silica gel strips. A lamp cavity where an LED light source assembly is placed and a wire groove where a power supply communication plug connector is placed are sequentially formed below the waterproof plate, and a bottom plate is arranged below the wire groove.

Owner:广东恒辰光电科技有限公司

Method for preparing organosilicon sealant for automobiles

InactiveCN109536047AHigh mechanical strengthSeal friction resistance is smallNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyvinyl alcoholSealant

The invention discloses a method for preparing an organosilicon sealant for automobiles. The organosilicon sealant is mainly prepared through mixing 50-60 parts of silicone resin, 20-25 parts of acrylic emulsion, 5-8 parts of polyvinyl alcohol, 2-4 parts of sodium metaaluminate, 10-12 parts of glass fibers, 6-9 parts of butyl acrylate, 20-25 parts of nano calcium carbonate, 3-4 parts of accelerant-D, 5-7 parts of cetylamine, 7-10 parts of sodium lauryl sulfate and 100-120 parts of deionized water. According to the organosilicon sealant prepared by the method, the silicone resin serves as a base material, and characteristics such as wear resistance, corrosion resistance and strength of the rubber are effectively enhanced by the glass fibers and the nano calcium carbonate; under the action of joint cooperation of all the ingredients, the sealant prepared by the method has the advantages that the mechanical strength is enhanced obviously, the frictional resistance of sealing is low, the lubricating effect is good, and the sealing performance of the sealant is greatly improved; and the sealant prepared by the method is long in sealing time and good in insulating property.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

Semi-hermetic packaging device of optical device and semi-hermetic packaging process

The invention discloses a semi-hermetic packaging device of an optical device and a semi-hermetic packaging process. The semi-hermetic packaging device comprises a main engine cabin, a first side cabin and a second side cabin. A center cabin is arranged in the main engine cabin. The first side cabin and the second side cabin are fixedly arranged on the two sides of the center cabin correspondingly. A first sealing door is arranged between the first side cabin and the center cabin, and a second sealing door is arranged between the second side cabin and the center cabin. An inlet sealing door isarranged on the side face of the first side cabin, and an outlet sealing door is arranged on the side face of the second side cabin. The main engine cabin and the center cabin are electrically connected. The main engine cabin is connected with an inert gas conveying device, and an inert gas conveying pipeline is connected between the main engine cabin and the center cabin. An upper end sealing opening is formed in the upper portion of the main engine cabin. A side face sealing opening is formed in the front portion of the center cabin. A heating device is mounted in the first side cabin. Thesemi-hermetic packaging device of the optical device and the semi-hermetic packaging process are easy to operate, water vapor can be effectively stopped from entering the optical device, and the service life of the optical device is prolonged.

Owner:四川华拓光通信股份有限公司

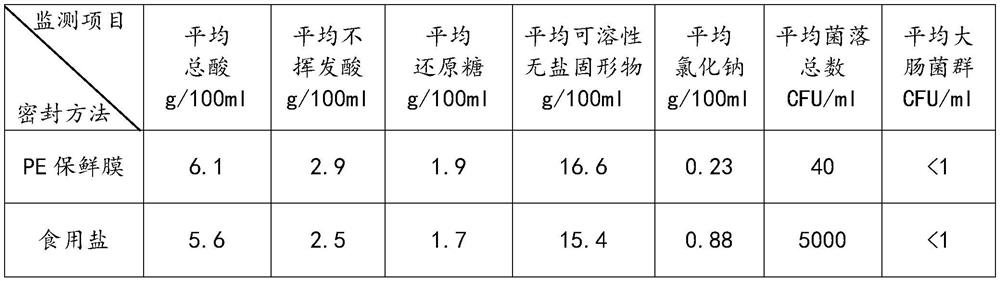

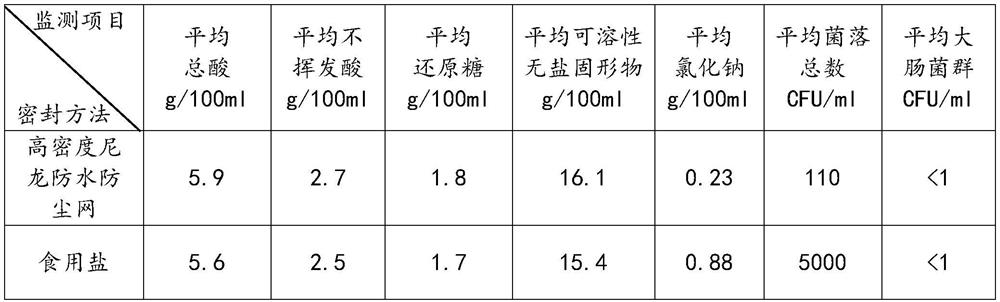

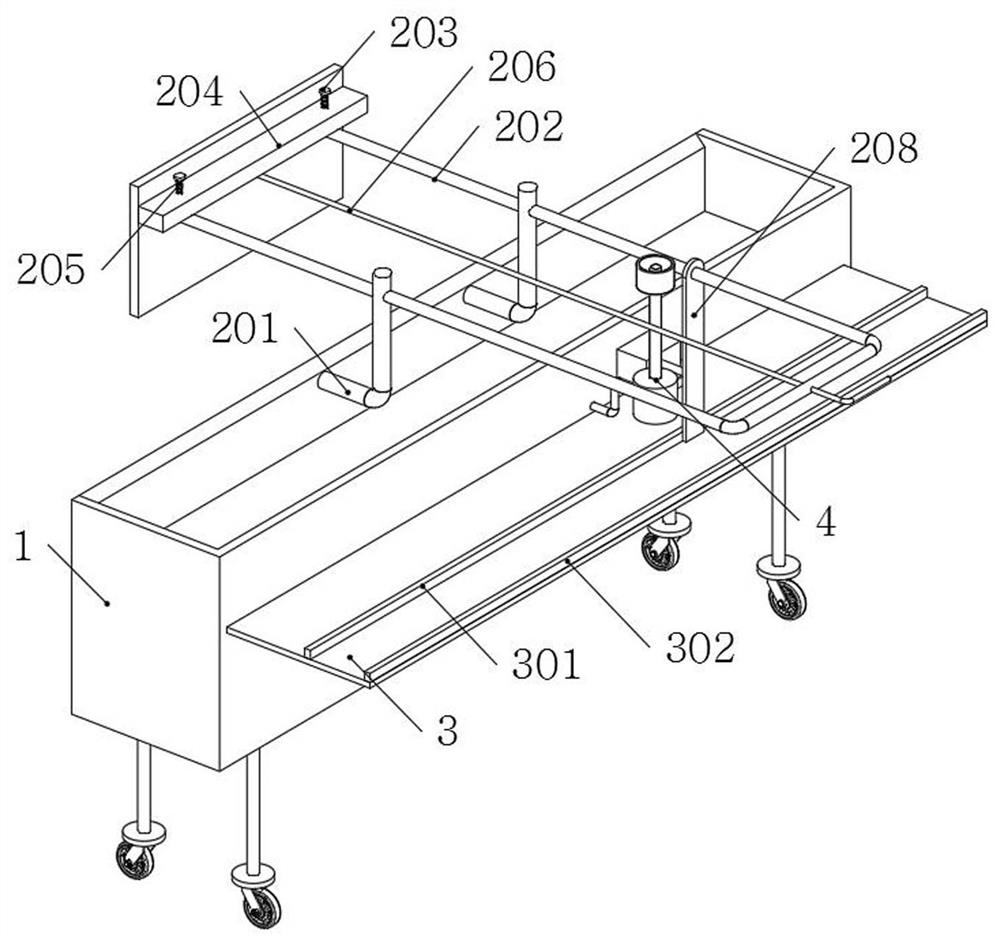

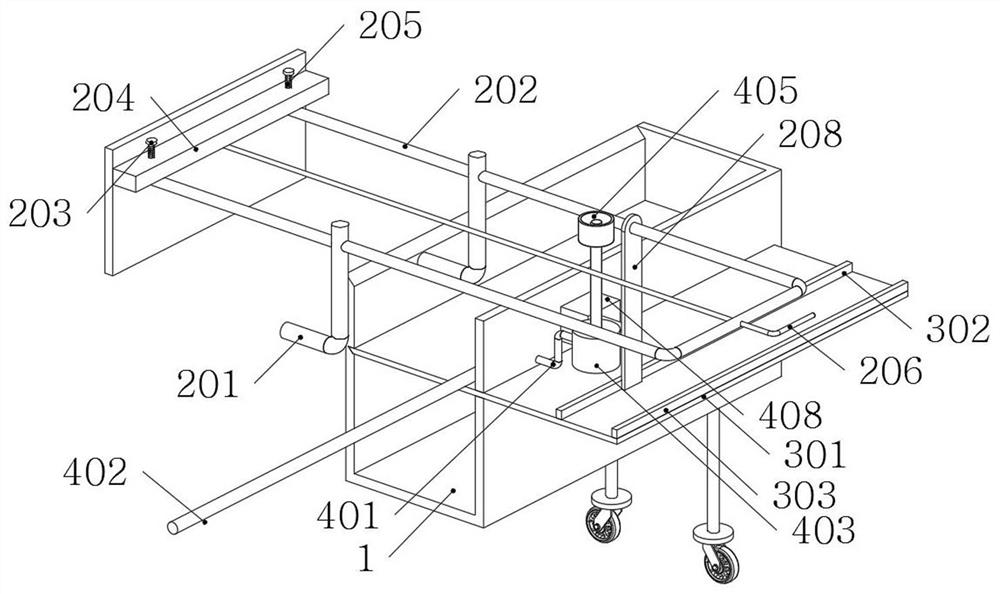

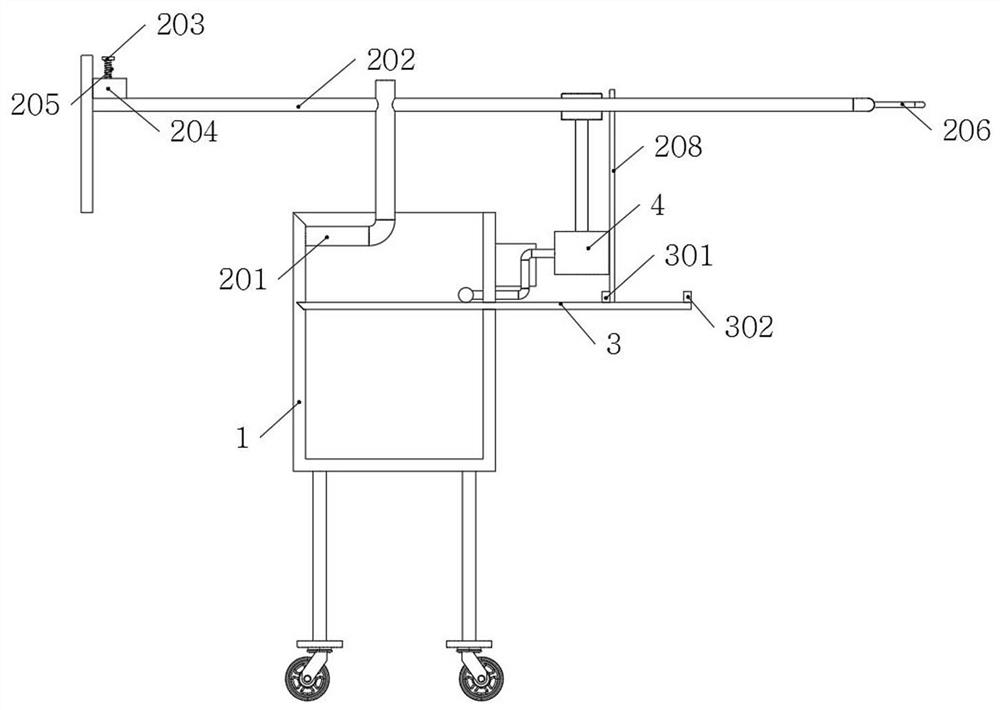

Sealed airing method of red-water sun-cured vinegar

The invention discloses a sealed airing method of red-water sun-cured vinegar, which comprises the following steps of: after vinegar grains which are maturely fermented by acetic acid are put into a pottery clay airing jar, performing all-directional covering and sealing on a strictly disinfected and sterilized pottery clay jar opening by adopting a PE (Poly Ethylene) preservative film or a high-density nylon waterproof and dustproof net, covering a jar cover, and airing in an open air drying yard for esterification reaction, so as to obtain the red-water sun-cured vinegar. The sealing is uncovered after one summer of solarization, the jar is manually turned over to exchange the positions of vinegar grains in the jar up and down, and the vinegar grains are treaded tightly to exhaust air, then the jar opening is continuously covered in all directions to isolate air, pollutants and the like, so that the effects of preserving moisture and preventing infectious microbe pollution are achieved, and after three summer of solarization, the vinegar is sprayed and unsealed, the sealing is uncovered, and the sealed airing is finished. According to the method, new substances are not introduced into sealed airing, and the original flavor of the red-water sun-cured vinegar is kept to the maximum extent; the sealing airing method is long in sealing time, good in sealing effect and easy and quick to operate, and bad fermented grains generated by vinegar fermented grain contamination are avoided.

Owner:贵州赤水古法酱香晒醋有限责任公司

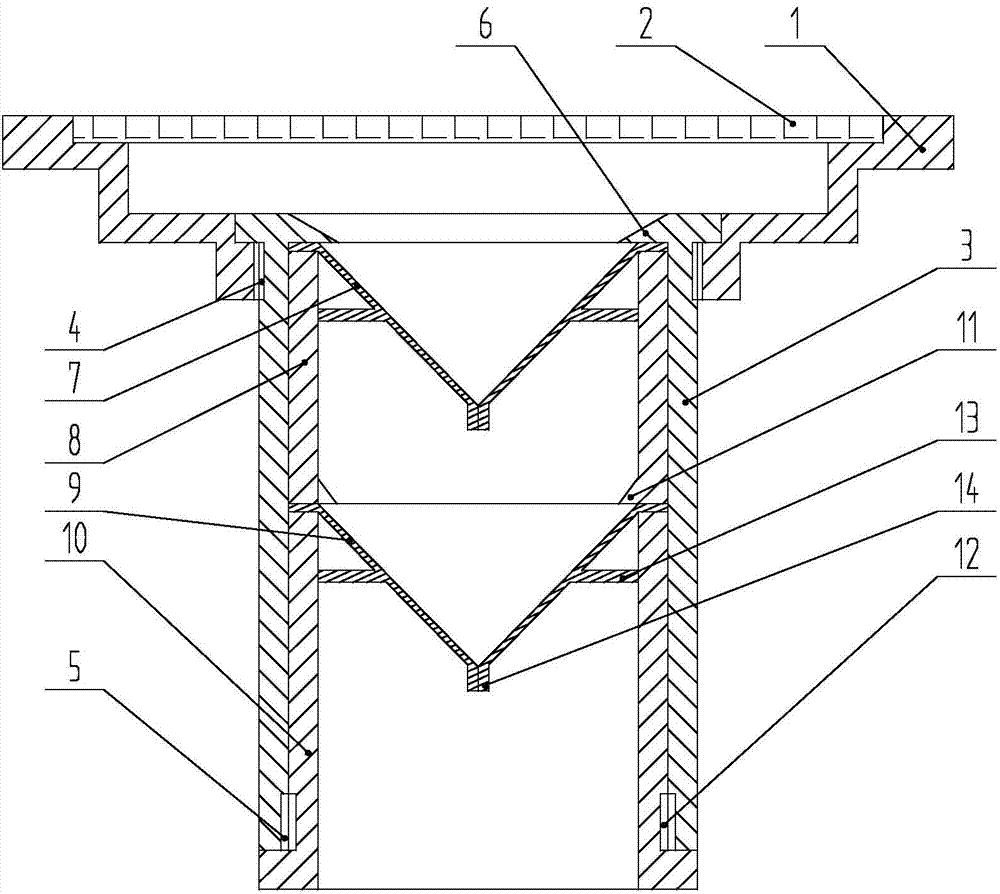

Slag removal device of chemical production boiler

ActiveCN113669746ALong sealing timeReduce dust spreadLighting and heating apparatusSlagProcess engineering

The invention provides a slag removing device of a chemical production boiler, relates to the technical field of slag removing devices, and solves the problem that after slag is scraped into a collecting box, the slag falls into the collecting box through gravity, so that dust is easily dispersed due to falling of the slag, and the body health of an operator is influenced. The slag removing device of the chemical production boiler comprises a collecting box, a cleaning part and a dust suction part, wherein the collecting box is placed on the ground. Through the arrangement of an inserting groove, the inserting groove is formed in the collecting box, the head end of a baffle is inserted into the inserting groove, and the inserting groove is of an inclined groove-shaped structure, so that on one hand, sealing of the collecting box can be achieved through cooperation of the baffle and the inserting groove, dust scattering caused by the fact that residues fall into the collecting box is prevented, and on the other hand, the inclined inserting groove can prevent slag from remaining in the inserting groove, so that the baffle and the inserting groove are not tightly sealed.

Owner:南通汇顺化工有限公司

Copper color aluminum alloy coloring system

The invention discloses a purple bronze aluminum alloy coloring system. The purple bronze aluminum alloy coloring system comprises a sulfuric acid tank used for anodizing an alloy profile, a coloring tank for electrolytically coloring the alloy profile, a hole sealing tank for sealing holes of the alloy profile, a rinsing tank for rinsing residual tank liquor of a hole sealing process, an electrophoresis tank for electrophoresis of the alloy profile and a curing unit for curing the alloy profile, and the sulfuric acid tank, the coloring tank, the hole sealing tank, the rinsing tank, the electrophoresis tank and the curing unit are sequentially connected. By means of the purple bronze aluminum alloy coloring system, the yield of purple bronze electrophoresis alloy profile products can be greatly increased.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Venous retention needle suite with hirudin anticoagulation tube sealing device

InactiveCN102068731BGood anticoagulant effectReduce workloadSurgeryDiagnostic recording/measuringVeinInsertion stent

The invention provides a venous retention needle suite with a hirudin anticoagulation tube sealing device, which comprises a casing, a transparent tee joint and a transfusion joint, wherein the casing is guided by a puncture needle and inserted into a vein; the transparent tee joint is connected to a built-in isolated sealing plug at the rear end of the casing; the transfusion joint is connected with a transfusion tube or a blood taking tube; the transparent tee joint is connected with the transfusion joint by an extension tube; the transfusion joint is sealed by a sealed end cap; one end of the transparent tee joint connected with the extension tube forms a double-cavity joint; one end of the double-cavity joint is connected with the extension tube, and the other end of the double-cavityjoint is connected with a tube sealing device; and the tube sealing device comprises a liquid storing bag in a support and a roller which is arranged between the two side walls of the support and used for pushing the liquid in the liquid storing bag forwards. The venous retention needle suite with the hirudin anticoagulation tube sealing device can ensure that a tubular cavity of the retention needle is filled with the tube sealing liquid. The tube sealing liquid in the tube sealing device is hirudin diluent which has good anticoagulation effect and does not influence any index of serum test in blood.

Owner:天津百新生物技术研发有限公司

An anti-leakage natural gas shut-off device and its use method

ActiveCN111486342BImprove sealingImprove securityVessel mounting detailsVessel geometry/arrangement/sizeOil canNatural gas storage

The invention discloses an anti-leakage natural gas shut-off device and its use method, and relates to a natural gas shut-off device, which specifically includes a transport vehicle, a vehicle board and a natural gas storage tank. During the natural gas leakage process, when the natural gas leaks, it is discharged from the gas outlet pipe. The gas sensor recognizes that there is a natural gas leak, and the motor is first turned on by the controller. After a period of time, the meshing effect of the gear and the rack rod, and the sealing is good, and the safety is increased; the outlet pipe is blocked by the way of sealing oil flow, when In the event of leakage, the sealing oil can be added automatically, thereby prolonging the sealing time, reducing the excessive addition of sealing oil, and reducing the waste of resources; the vibration-absorbing bracket can buffer the shaking of the natural gas storage tank during transportation, and improve the stability of the natural gas storage tank during transportation. Increased natural gas storage tank stability reduces the likelihood of valve misalignment, thereby preventing the increased likelihood of leaks.

Owner:KUNSHAN ENERGY HUNAN HUANGGANG LIQUEFIED NATURAL GAS

Rock core sealing device and sealing method thereof

ActiveCN103114849BImprove sealingReal-time monitoring of pressure changesFluid removalRock coreEngineering

Owner:PETROCHINA CO LTD

UV led packaging method

ActiveCN106531858BLong sealing timeDelay agingSolid-state devicesSemiconductor devicesEpoxyUltraviolet lights

The invention discloses a method for packaging ultraviolet LEDs, which includes the following steps: (11), a crystal-bonding step, fixing an ultraviolet LED chip in a crystal-bonding area in a cavity of a substrate; (12), a wire bonding step, using wires to The ultraviolet LED chip is connected to the relevant circuit terminal; (13), the plasma coating step, the substrate fixed with the ultraviolet LED chip is placed in the spraying room, and the spraying room is pumped into a low-pressure vacuum state, and the plasma is applied to the surface of the ultraviolet LED chip and the substrate cavity. Coating; (14), the step of sealing the cover plate, sealing the cover plate transparent to ultraviolet light on the mouth of the substrate cavity. The ultraviolet LED packaging method of the present invention can add another layer of protective film to the ultraviolet LED chip, which can delay the aging of the cover plate and prolong the sealing time of the cover plate. The mouth of the substrate cavity is sealed by a UV-transmissive cover plate, which avoids the problem of poor UV resistance of epoxy resin or silica gel and low light extraction efficiency.

Owner:QINGDAO JASON ELECTRIC

Aluminum Alloy Copper Salt Coloring Electrophoresis Process

ActiveCN105821461BRaise the pHLong sealing timeAnodisationElectrophoretic coatingsElectrophoresisAnodic oxidation

The invention discloses an aluminum alloy copper salt coloring electrophoresis process. The process comprises the following steps: (1) sulfuric acid groove liquid is prepared; and an alloy profile to be colored is mounted on a lifting frame; (2) the alloy profile is put in the groove liquid for anodically oxidized to generate a layer of oxide film with a film hole; (3) the anodically oxidized alloy profile is put in a copper salt electrolytic coloring groove for electrolytic coloring; (4) the colored alloy profile is sealed; (5) the residual groove liquid in the hole sealing process is washed by water; (6) the electrophoresis is performed for the alloy profile washed by the water; and (7) the alloy profile is cured after electrophoresis. The pH value of the hole sealing groove liquid is higher; the hole sealing distance is longer; a half hole sealing process is adjusted to a near all hole sealing process for preventing dissolving of copper; and the alloy profile is more stable after coloring, and is higher in corrosion resistance.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Tire repairing agent and preparation method thereof

PendingCN111253909ALong sealing timeSuitable for a wide temperature rangeOther chemical processesCrumb rubberEngineering

The invention relates to a tire repairing agent. The tire repairing agent comprises the following components: polyvinyl alcohol gel, ethylene glycol, water, an anti-settling agent, rubber particles, chitosan gel and fibers. With the tire repairing agent and the preparation method thereof, the tire repairing agent can be quickly and directly gathered at a punctured and perforated place in a sealable tire when the tire is punctured and perforated by external force, so gas in the tire is prevented from leaking from the punctured and perforated place in the tire and is sealed.

Owner:龙佳福

High-temperature and high-pressure air cylinder sealing assembly

ActiveCN113915526AGuaranteed sealed stateAvoid seal failureVessel mounting detailsEngine sealsEngineeringMechanical engineering

The invention relates to the technical field of machinery, and discloses a high-temperature and high-pressure air cylinder sealing assembly. The high-temperature and high-pressure air cylinder sealing assembly comprises an upper half air cylinder, a flange I at the bottom of the upper half air cylinder, a lower half air cylinder below the upper half air cylinder, a flange II at the top of the lower half air cylinder, and bolts and nuts for fastening the ends, away from the upper half air cylinder, of the flange I and the flange II. Buckling grooves are formed in the flange I and the flange II. Through the designed buckling grooves, a transmission air channel and a sealing clamping plate, when the operation of the air cylinders is influenced by high-temperature and high-pressure gas, the high-temperature and high-pressure gas passes through the transmission air channel to enter a buckling cavity formed after the buckling grooves in the flange I and the flange II are closed; and high-temperature and high-pressure gas pushes the sealing clamping plate to be clamped with a trapezoidal protrusion formed by the buckling cavity to form self-locking, so that when the upper half air cylinder and the lower half air cylinder tilt with one bolt as a fulcrum, the sealing clamping plate limits separation of the flange I and the flange II to complete sealing compensation, and the two air cylinders are kept in a sealed state.

Owner:宁波纽必得自动化科技有限公司

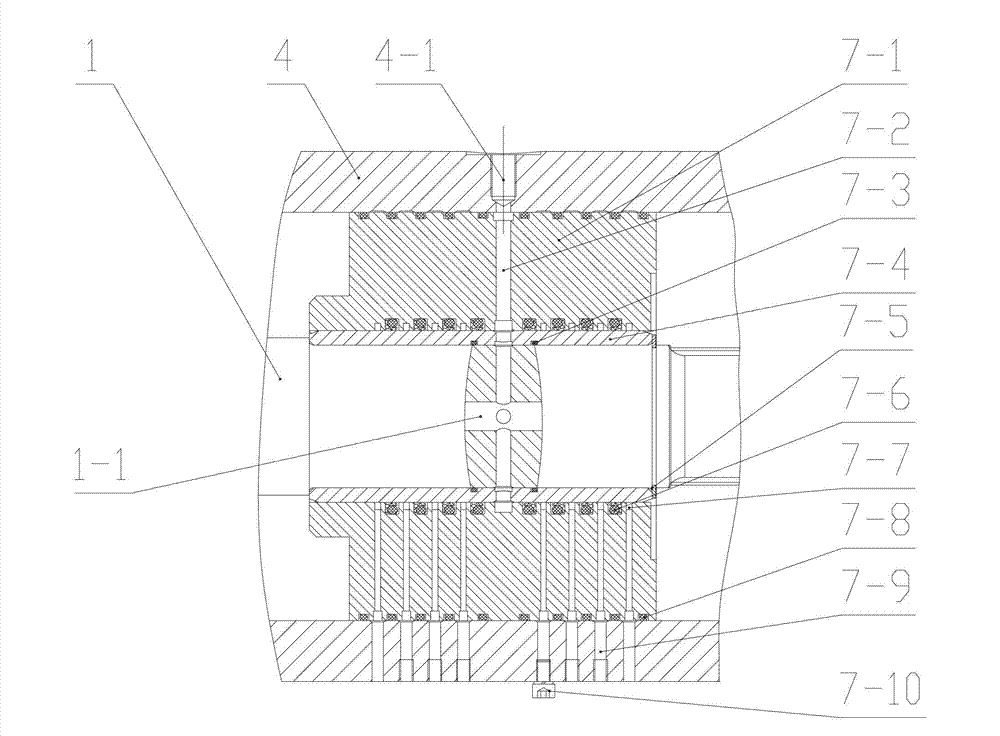

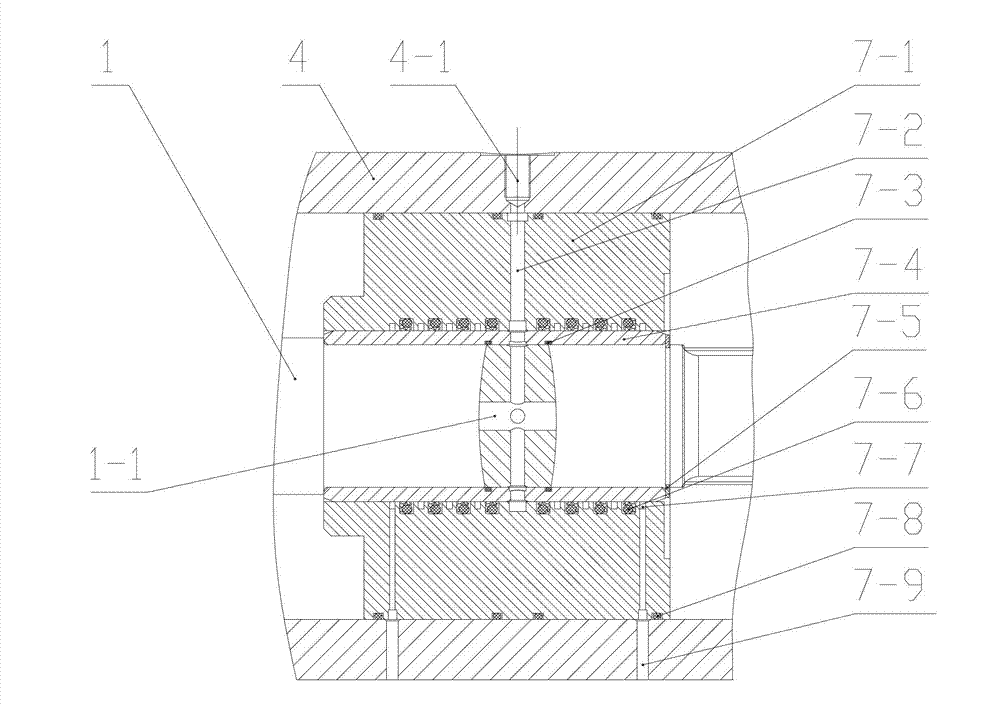

Multi-point sealing apparatus for auxiliary high-pressure water jet of cutting mechanism of digging device

ActiveCN103195423BImprove auxiliary cutting efficiencySolving Jet Seal ProblemsSlitting machinesHydraulic miningWater leakageInlet channel

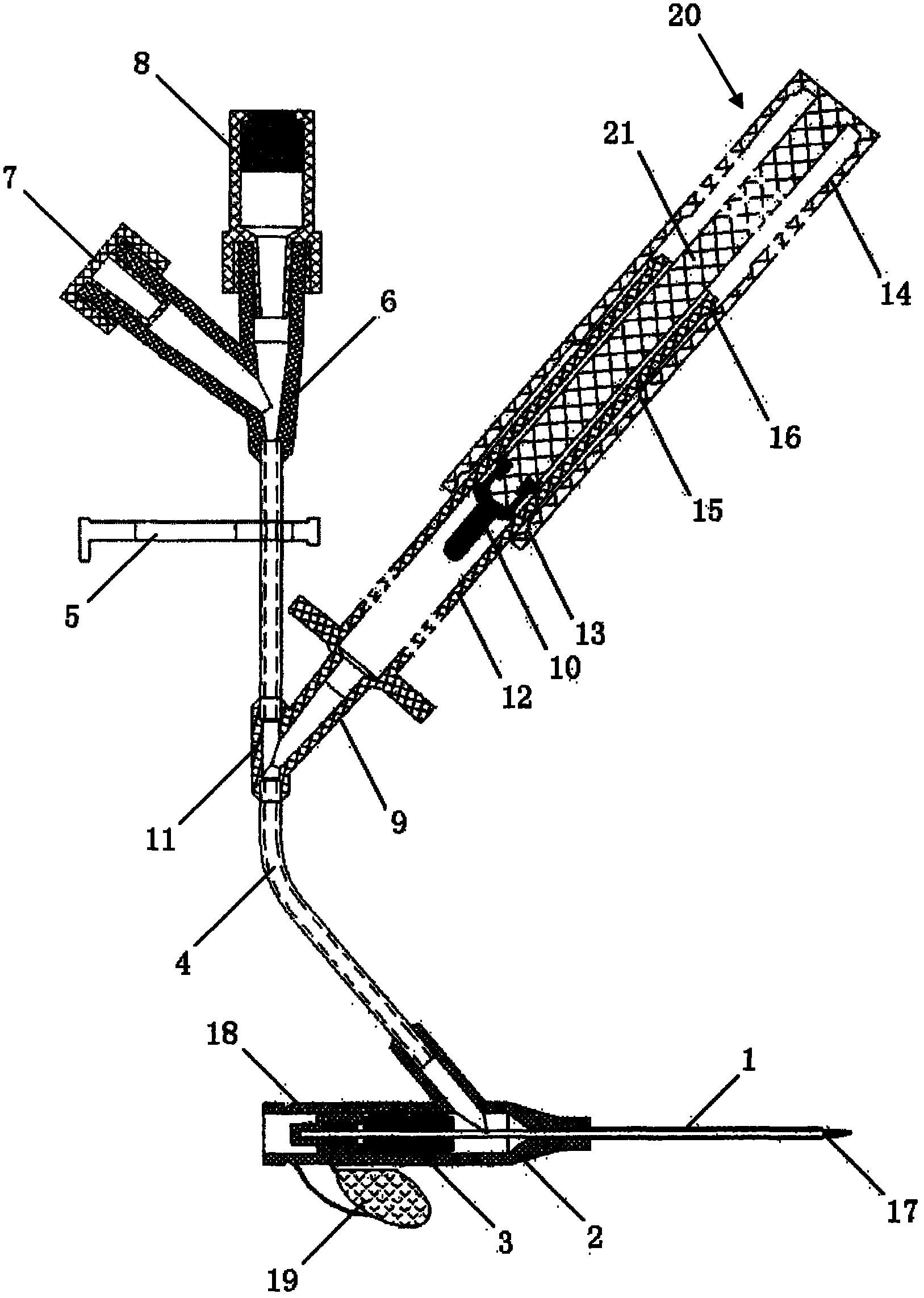

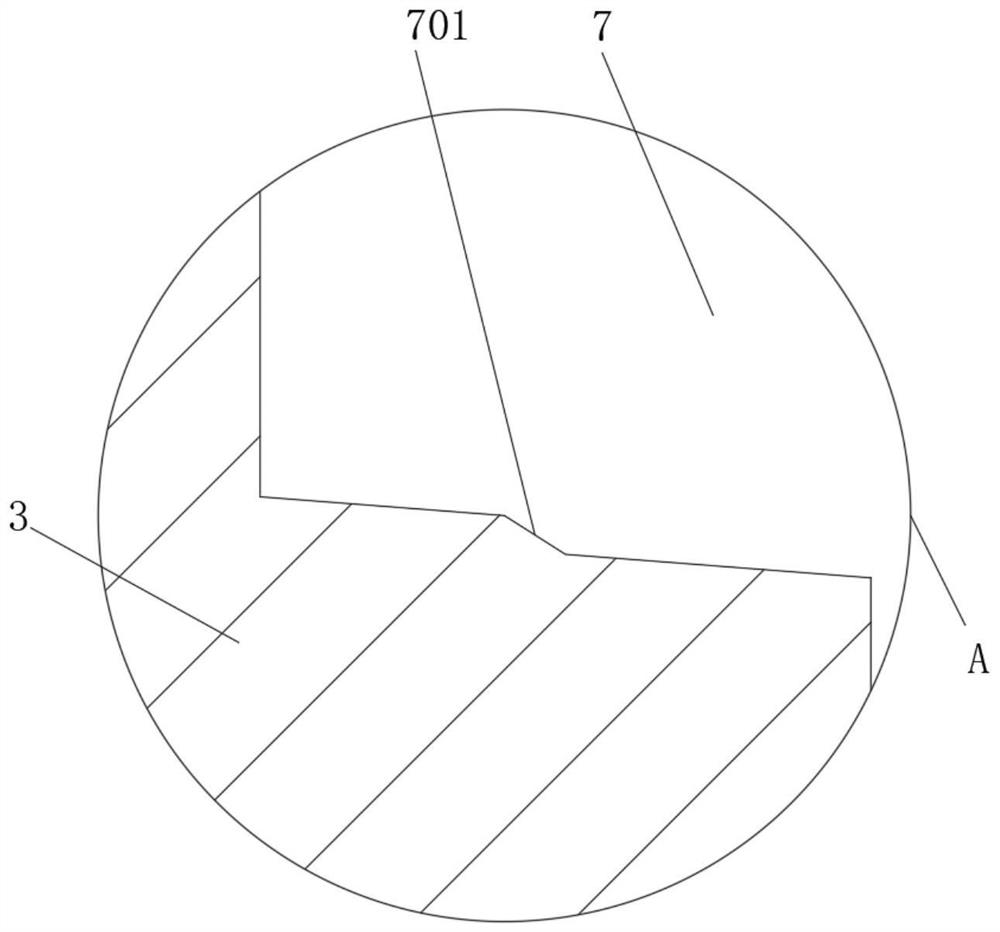

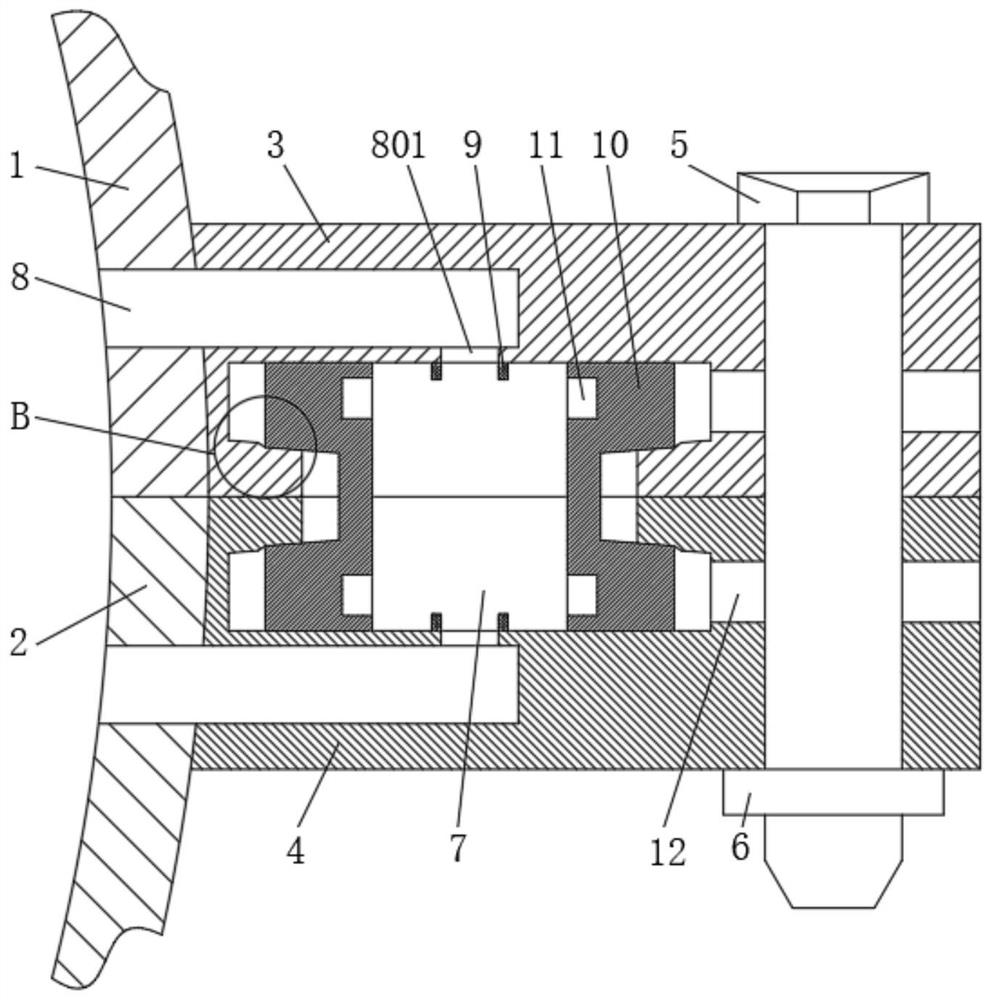

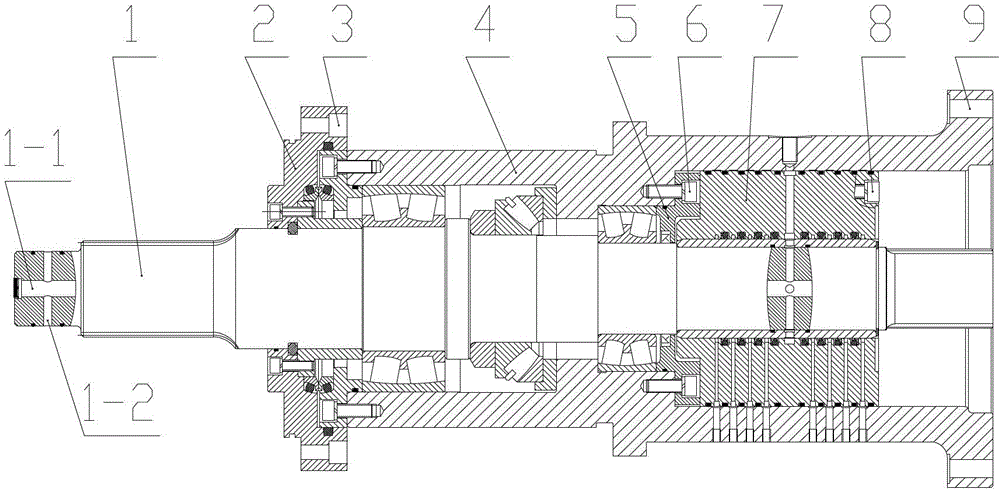

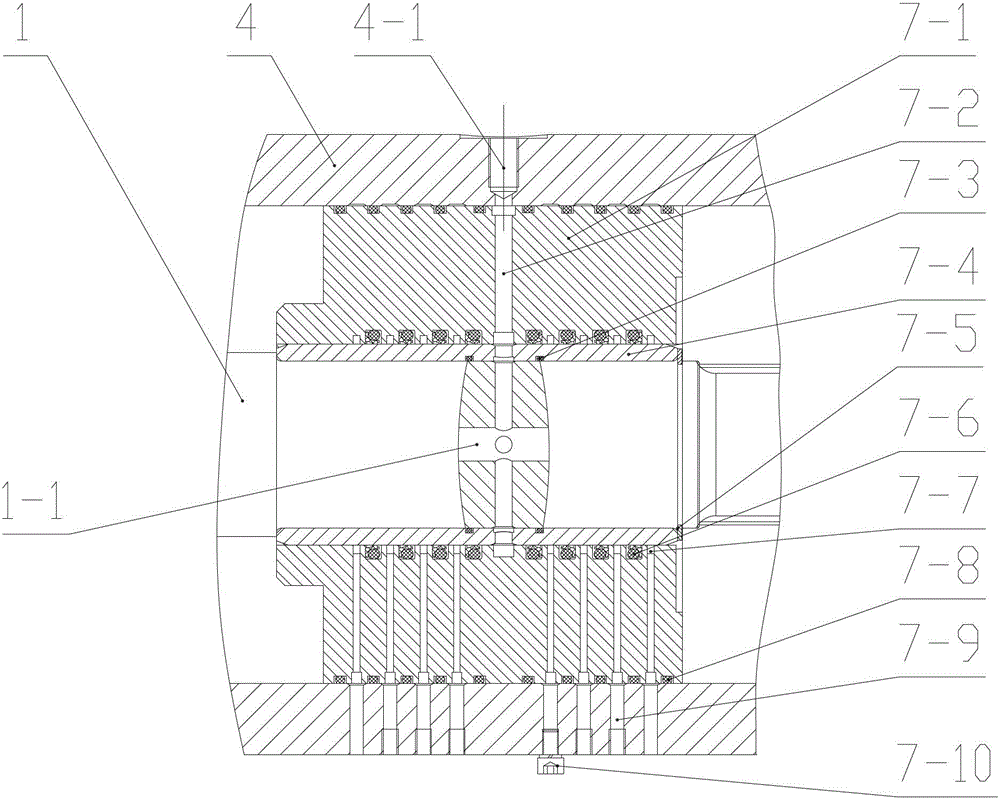

A multipoint sealing device for the auxiliary high-pressure water-jet of a mining equipment cutting mechanism, comprising a water-conducting casing (7-1) and a water-conducting sleeve (7-4); the water-conducting sleeve (7-4) and the water-conducting casing (7-1) are sequentially sleeved between the cutting shaft (1) and cutting tank (4) of the mining equipment cutting mechanism; a water-inlet channel (7-2) is provided radially through the water-conducting casing (7-1), the water-conducting sleeve (7-4) and the cutting shaft (1); the water-inlet channel (7-2) respectively communicates with the water inlet of the cutting tank (4) and the main flow channel (1-1) of the cutting shaft (1); the two sides of the water-inlet channel (7-2) are respectively provided with a first O-shape seal ring (7-3), a toothed combination seal (7-6) and a second O-shape seal ring (7-8); the water-conducting casing (7-1) is provided with a drainage groove (7-7) thereon; and the cutting tank (4) is provided with a water leakage channel (7-9) thereon in communication with the drainage groove (7-7). The multipoint sealing device solves the sealing problem of the auxiliary high-pressure water-jet of the mining equipment cutting mechanism, effectively sealing the high-pressure water having a pressure of less than 50 MPa, providing a long-lasting seal and good sealing effect, and improving the auxiliary cutting efficiency of the high-pressure water-jet.

Owner:CHINA UNIV OF MINING & TECH

Formula of packaging sealant

InactiveCN104804670AReduce failureLong sealing timeNon-macromolecular adhesive additivesBituminous material adhesivesStearic acidSealant

The invention discloses a formula of a packaging sealant. The formula comprises the following raw materials in parts by weight: 20-23 parts of calcium carbonate, 10-12 parts of bitumen resin, 3-3.4 parts of polyisobutene, 0.2-0.3 part of stearic acid, 22-24 parts of talcum powder, 9-9.8 parts of asbestos powder, 55-60 parts of cis-polybutadiene, 1-1.3 parts of argil and 1-2 parts of dibutyl phthalate. The sealant prepared from the formula can slow down the failure of seal effect and prolong seal time; experiments prove that compared with traditional sealants (only including calcium carbonate, bitumen resin, polyisobutene, talcum powder, asbestos powder and cis-polybutadiene), the sealant can prolong the shelf life by 3-5 days when the same object is sealed under the same condition.

Owner:JURONG DINGSHENG CARTON PACKING

Furnace mouth bottom automatic protection device

PendingCN112683064ALong sealing timeReduce the overall heightCharge manipulationControl devices for furnacesManufacturing engineeringReciprocating motion

The invention discloses a furnace mouth bottom automatic protection device which comprises a furnace door opening; a furnace door body is arranged on the upper side of the furnace door opening; a furnace mouth bottom table is arranged on the lower side of the furnace door opening; a guide rail is fixedly connected to the outer side of the furnace mouth bottom table; a skip car body is arranged on the guide rail in a sliding mode; the skip car body is jointly composed of a skip car platform and a skip car chassis; the upper surface of the skip car platform is flush with the upper surface of the furnace opening bottom table; connecting wheels on the lower side of the skip car chassis are correspondingly arranged on guide rails; connecting rods are rotatably connected to the two sides of the skip car chassis; and the other ends of the connecting rods are rotationally connected to the left and right sides of the front surface of the furnace door body. In the furnace mouth bottom automatic protection device, the skip car obtains a horizontal reciprocating motion traction force through the lifting power of the furnace door; the skip car and the furnace door realize position interlocking and motion synchronization through the left and right connecting rods; the furnace door is opened to finish automatic protection of the skip car to the bottom of the furnace mouth; and the reliable sealing time of the furnace door and the bottom of the furnace mouth is prolonged.

Owner:SHANDONG YIRAN ENVIRONMENTAL PROTECTION TECH CO LTD

A large-flow floating ball floor drain

The invention discloses a large-flow floating ball floor drain, which comprises a floor funnel, a floor drain cover, a water retaining pipe, a water guide pipe and an outer casing, a floor drain panel is arranged outside the edge of the upper end of the floor funnel, the upper and lower ends of the water retaining pipe are sealed, and the water retaining pipe is worn on the top At the bottom of the floor funnel, there is a water inlet on the upper end of the water retaining pipe. There is a gap between the upper end of the water retaining pipe and the floor drain cover. The gap between the water retaining pipe and the floor funnel forms an upper water seal groove. There is an overflow channel between the water guide pipe and the water retaining pipe, and the gap between the water guide pipe and the water retaining pipe forms an overflow tank. The upper part of the water guide pipe is provided with a water collecting bucket, and a floating ball is arranged in the water collecting bucket, which is located on the side of the overflow tank. The aqueduct is provided with an overflow port, the outer casing is sleeved outside the water retaining pipe, the lower end of the outer casing is sealed, and the lower side of the outer casing is provided with drainage outlets at intervals along the circumferential direction, and the gap between the outer casing and the aqueduct located below the drainage outlet Form the lower water seal groove. The invention has large drainage volume, fast drainage speed, good sealing effect and can effectively prevent backwater.

Owner:佛山市澳钢金属制品有限公司

A kind of slag cleaning device for chemical production boiler

The invention provides a slag removal device for a chemical production boiler, which relates to the technical field of slag removal devices, and solves the problem that the slag falls into the collection box due to the slag falling into the collection box after being scraped into the collection box. Falling will easily lead to the spread of dust, which will affect the health of the operator. A slag cleaning device for a chemical production boiler includes a collecting box, a cleaning part and a dust suction part; the collecting box is placed on the ground. Through the setting of the slot, there is a slot on the collection box, and the head end of the baffle is plugged into the slot, and the slot is an inclined groove structure, so that on the one hand, the cooperation between the baffle and the slot can realize The sealing of the collection box prevents the dust from spreading due to the slag falling in the collection box; on the other hand, the inclined slot prevents the slag from remaining in the slot, which leads to the sealing of the baffle and the slot Not tight.

Owner:南通汇顺化工有限公司

A special compensator for maintenance-free pipe gallery system

ActiveCN106838524BNo thrustLarge compensation distanceEngine sealsPipeline expansion-compensationOuter CannulaMechanical engineering

The invention provides a special compensator for a maintenance-free pipe rack system. The compensator is located on a compensation mechanism mounting frame at least in the length direction of a pipeline; the compensation mechanism mounting frame is mounted on the ground; two ends of the compensator are respectively connected with an upstream pipe body and a downstream pipe body. The compensator is characterized by comprising an inner movable sleeve, an outer sleeve and an end pipe; the end part of the inner movable sleeve is fixed at the lower middle part in the outer sleeve; the end part of the end pipe is fixedly fitted to the inner wall of the top end of the outer sleeve, thus forming a three-layer sleeve structure. The special compensator for the maintenance-free pipe rack system has the outstanding characteristics of no thrust, large compensation distance, low operation cost and the like, and can meet the urban heating requirement.

Owner:JIANGSU FENGHE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com