Sealed airing method of red-water sun-cured vinegar

A technology of Chishui sun-dried vinegar and sealing parts, which is applied in the production field of sun-dried vinegar, can solve the problems of short sealing time, bad fermented grains, and high labor intensity, and achieve the effect of long-lasting air barrier, simple and fast operation, and long sealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for sealing and drying Chishui vinegar, comprising the following steps:

[0019] Step 1: Loading the unstrained spirits: manually put the fermented and mature vinegar unstrained spirits into the clay sun-drying altar, step on it tightly and compact without leaving any gaps, after filling the altar, clean the mouth of the altar first to ensure that there is no foreign matter before cleaning with a disinfectant Disinfection;

[0020] Step 2: Seal the altar: Cover and seal the mouth of the sterilized pottery clay drying altar in all directions according to the ratio of PE cling film and the area of the altar mouth of 2.5:1, and the PE cling film is tightly overlapped and glued to the smooth altar mouth After checking that there is no air leakage, cover the altar and place it in the open air to dry for esterification.

[0021] Step 3: Check the seal of the altar: remove the plastic wrap after sealing the altar for 5-6 months, first sterilize the mouth of the alt...

Embodiment 2

[0025] A method for sealing and drying Chishui vinegar, comprising the following steps:

[0026] Step 1: Filling the unstrained spirits: the fermented and mature vinegar unstrained spirits are manually loaded into the clay sun-drying altar, and compacted tightly without leaving any gaps. After filling the altar, clean the mouth of the altar first to ensure that there is no foreign matter before disinfecting with a disinfectant Sterilize.

[0027] Step 2: Seal the altar: Cover and seal the sterilized clay altar mouth in all directions according to the high-density nylon waterproof and dustproof net and the high-density nylon waterproof and dustproof net with a ratio of 2.5:1. The nylon waterproof and dustproof net needs The tether is fixed at the mouth of the altar, and after checking that there is no air leakage, the altar cover is covered. The nylon waterproof and dustproof net under the rope is folded into the altar cover, and placed in the open air to dry for esterification...

experiment example

[0032] Using Example 1 and Example 2 as a reference for the experiment, the following specific data were obtained.

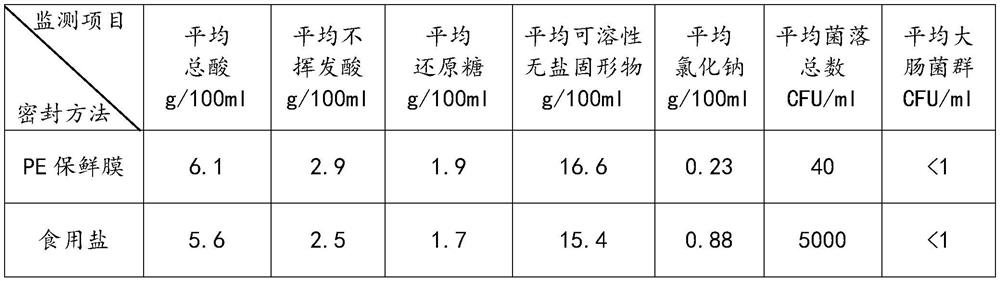

[0033] The relation of embodiment 1 sealing method and physical and chemical index, microbial index is as shown in table 1:

[0034]

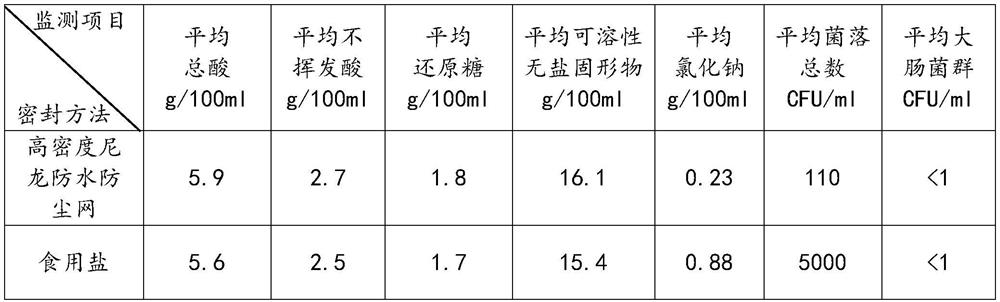

[0035] Table 1 Embodiment 2 The relationship between sealing method and physical and chemical index, microbial index is as shown in table 2:

[0036]

[0037] Table 2

[0038] The indicators of the vinegar unstrained spirits sealed in Example 1 are better than those of the vinegar unstrained spirits sealed in Example 2, and the indicators of the vinegar unstrained spirits sealed in Example 1 and Example 2 are better than the traditional salt sealing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com