An electrophoresis test device and a mixing tank process using the same

A test device and electrophoresis technology, used in electrophoretic plating, electrolytic coatings, coatings, etc., can solve problems such as pinholes, inability to mass-produce, shrinkage holes, etc., to reduce the risk of quality accidents, avoid batch quality accidents, Avoiding and cost-wasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

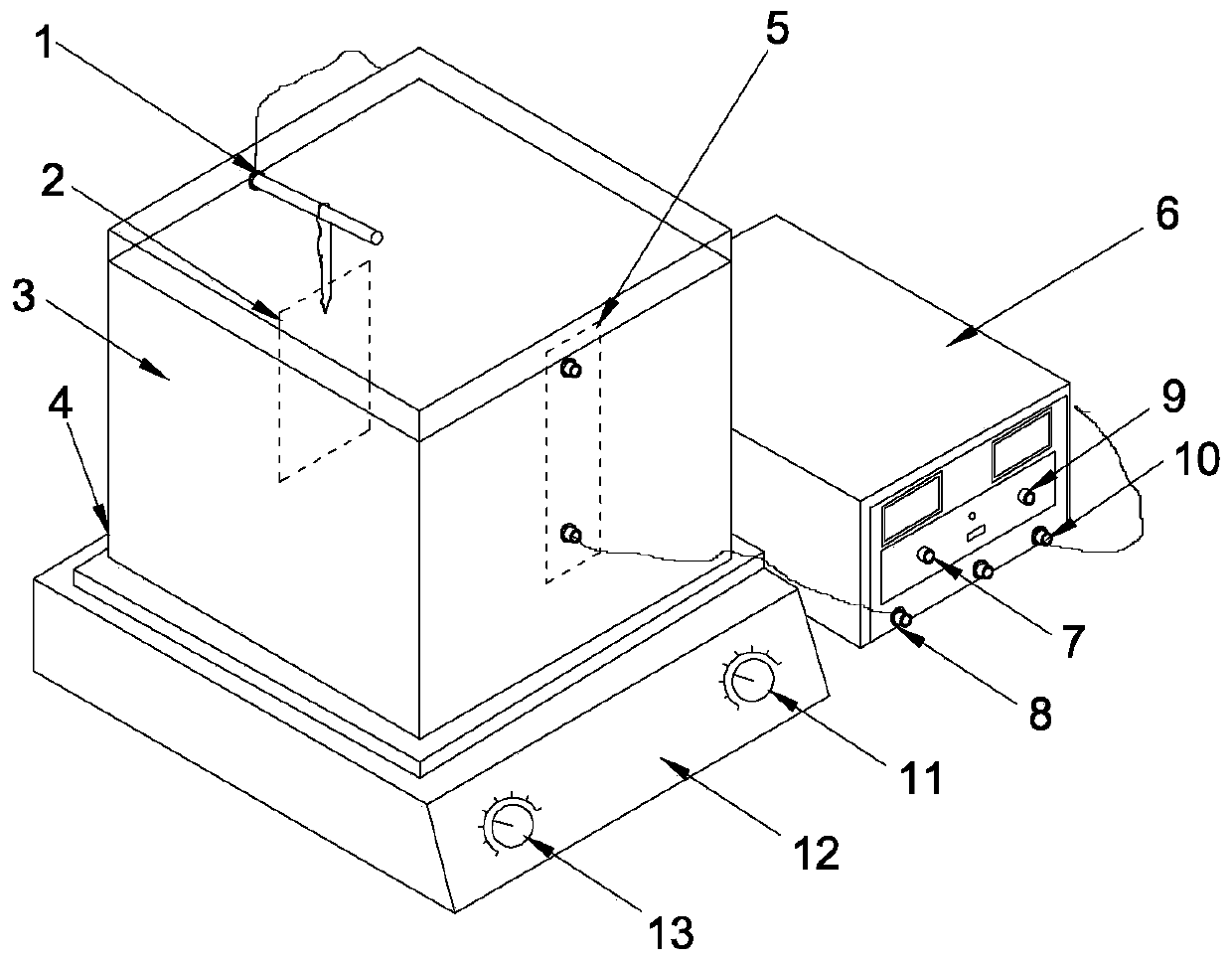

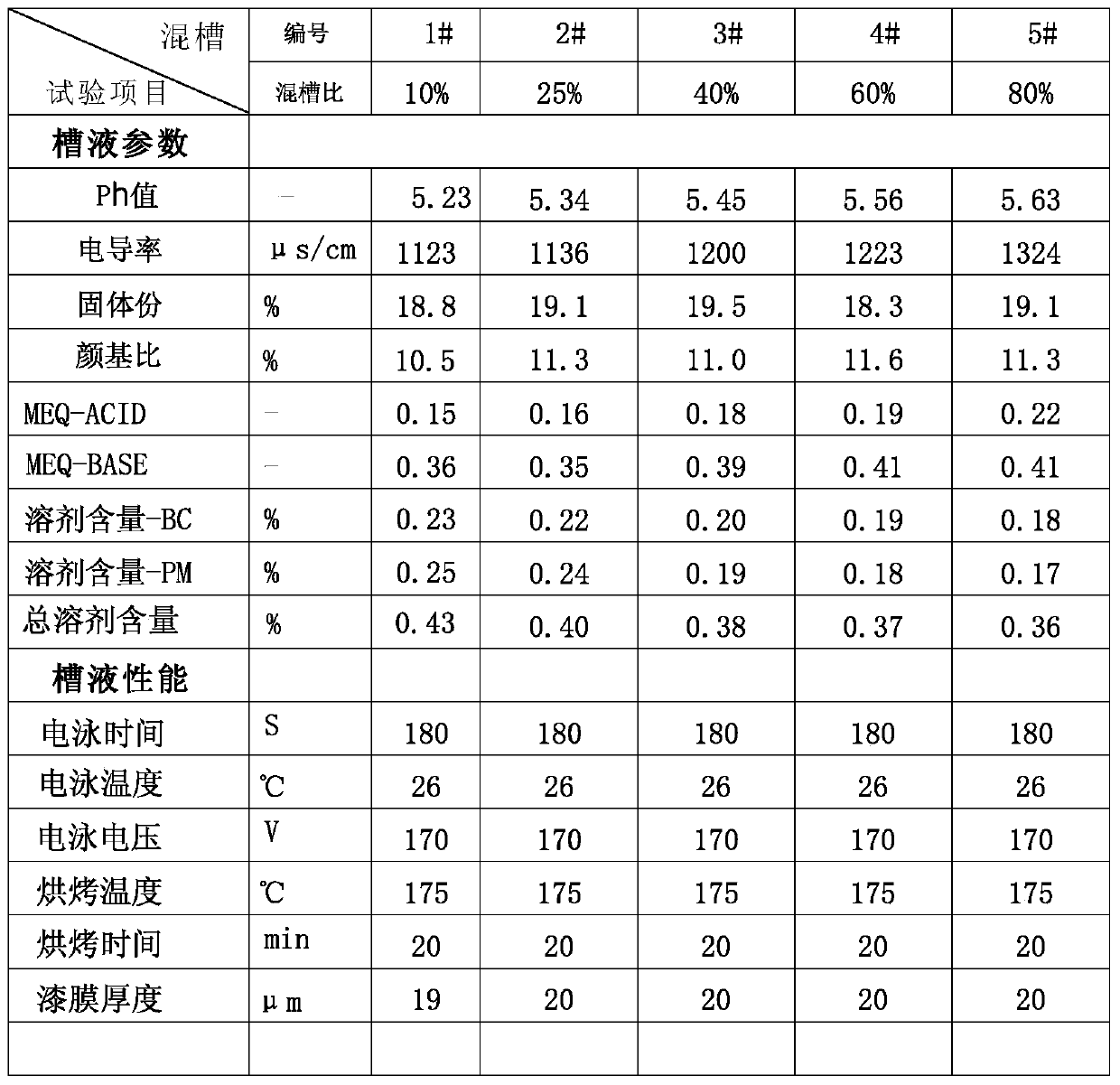

[0028] Such as figure 1 , figure 2 As shown, an electrophoresis test device includes: an electrophoresis test small tank 4, a voltage-stabilizing adjustable DC power supply 6 and an adjustable temperature stirrer 12, the electrophoresis test small tank 4 includes a cathode 1, an electrophoresis plate 2 and an anode 5, and the anode 5 The positive ratio of the area to the cathode 1 is 1:4. The electrophoretic test small tank 4 is used to hold the electrophoretic paint 3. The voltage-stabilized and adjustable DC power supply 6 is equipped with a positive pole 8, a negative pole 10, a voltage adjustment knob 7, and a current adjustment knob 9. ; Adjustable temperature mixer 12 is equipped with speed adjustment knob 13, temperature adjustment knob 11 and so on. Place the electrophoresis test small tank 4 stably on the temperature-adjustable stirrer 12, and place the voltage-stabilizing and adjustable DC power supply 6 on the same plane beside it;

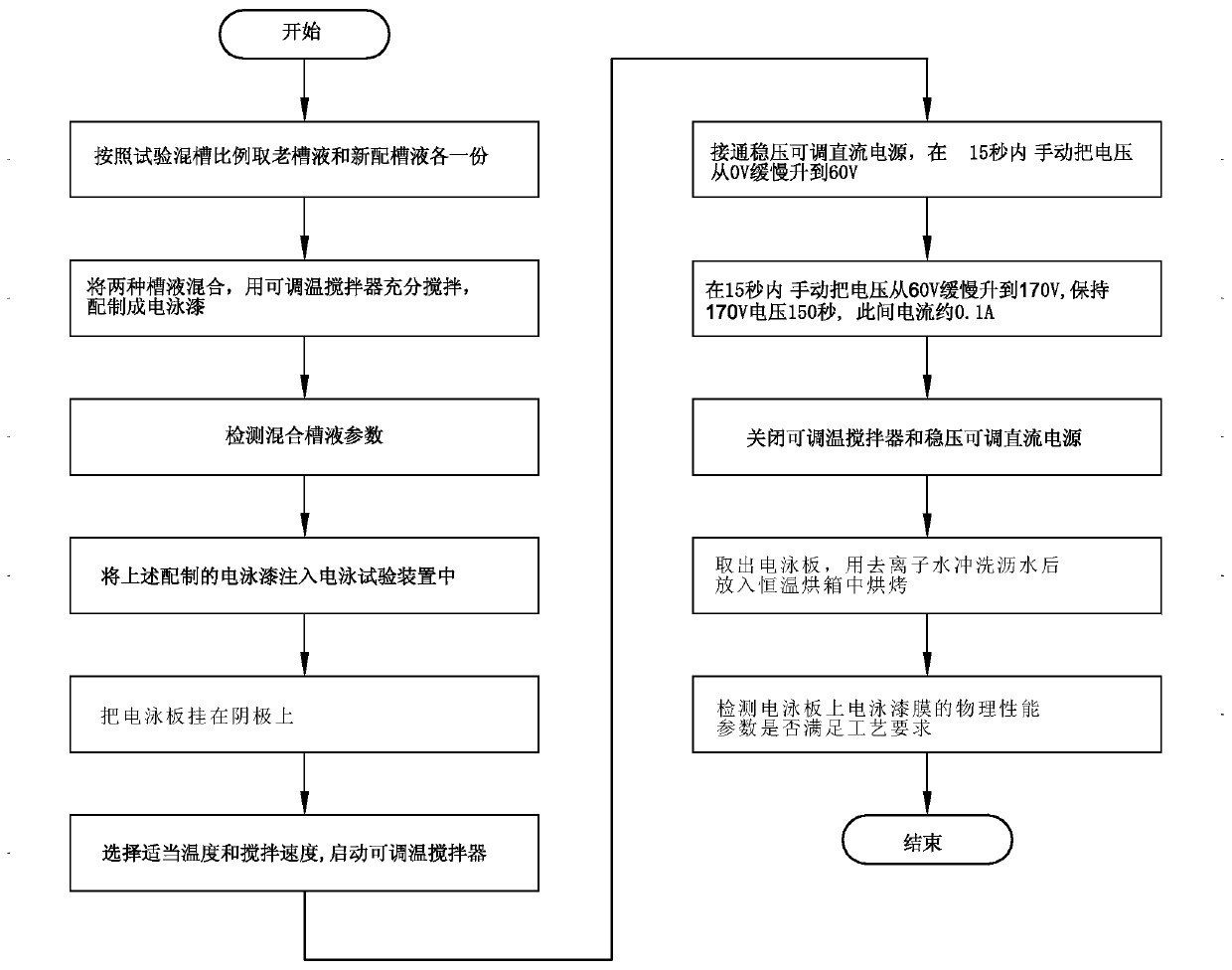

[0029] A kind of mixing tank ...

Embodiment 2

[0042] The liquid surface is 19mm away from the cathode 1 conductive rod, and the temperature-adjustable stirrer is rotated from 12 to 25°C. In step B, the stirring speed is 2200 rpm. In step G, the voltage is slowly raised from 0V to 62V within 16 seconds. In step H, the Slowly increase the voltage from 62V to 172V within 16 seconds and maintain the voltage of 172V for 148 seconds. The current is controlled at 0.15A. In step J, the constant temperature oven is controlled at 173°C and baked for 19 minutes. The positive ratio of the area of the anode 5 to the surface of the cathode 1 is 1: 5.

Embodiment 3

[0044] The liquid surface is 21mm away from the conductive rod of cathode 1, and the temperature-adjustable stirrer is rotated at 12 to 27°C. In step G, the voltage is slowly increased from 0V to 58V within 14 seconds, and in step H, the voltage is slowly increased from 58V to 168V within 14 seconds. Maintain the voltage of 168V for 152 seconds, control the current at 0.13A, control the constant temperature oven at 176°C in step J, bake for 21 minutes, and the ratio of the area of the anode 5 to the area of the cathode 1 is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com