Pressing plate structure of filter cotton of painting dynamic pressure chamber for automobile coating

A technology of filter cotton and pressing plate, applied in spray booths, spraying devices, etc., can solve the problems of large manpower, time disassembly, difficult adjustment, and time-consuming, etc., to achieve low manufacturing cost, avoid batch quality accidents, and post-maintenance The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

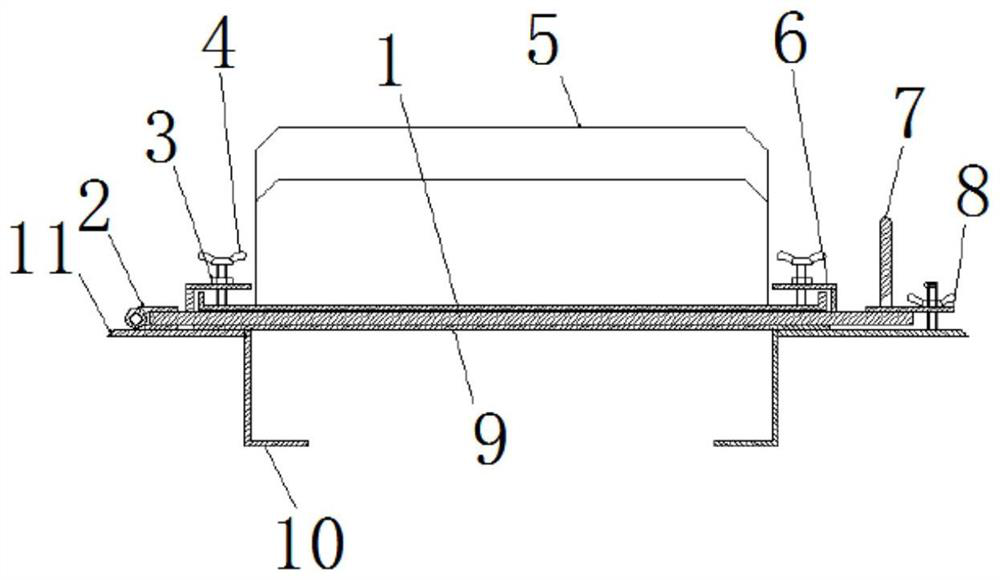

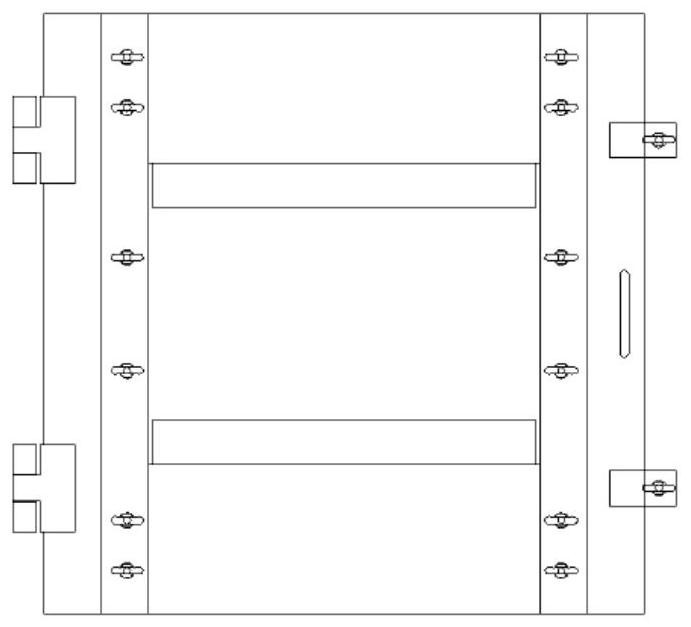

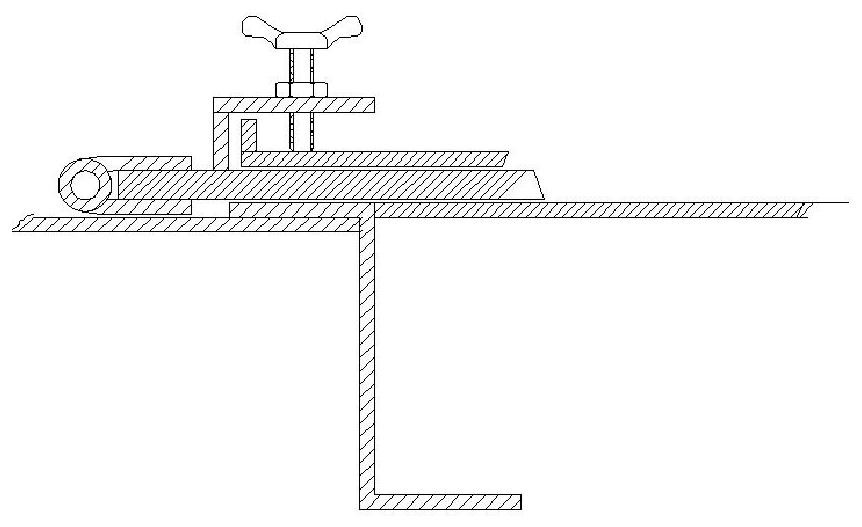

[0033] The pressure plate structure of the filter cotton in the dynamic pressure chamber, the pressure plate frame 1 is in the shape of a back, and it is made of flat steel welding. One end is welded together with the bottom plate 11 of the dynamic pressure chamber through two hinge hinges 2, and the left and right sides of the pressure plate frame are respectively The ferrule plate 6 with the shape of the card slot is welded, and a row of six hexagonal nuts 3 and positioning bolts 4 are arranged directly above the ferrule plate 6 according to a certain proportion. The hexagonal nuts 3 and the positioning bolts 4 are used together; the positioning bolts are butterfly bolts .

[0034] Two L-shaped windshields 5 are made of steel plates and are movable baffles. They are stuck on the inner side of the ferrule plate 6 one after the other, and can move back and forth to adjust the laminar flow of the wind pressure and wind direction in the spray booth. effect. After the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com