Textile apparatus and method for manufacturing melt-blown fiber

A technology of textile equipment and melt-blown fibers, which is applied in the field of textile equipment for making melt-blown fibers, can solve the problems of expensive equipment, complicated operation steps, increase in the price of melt-blown fibers, etc., and achieve the effect of prolonging the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

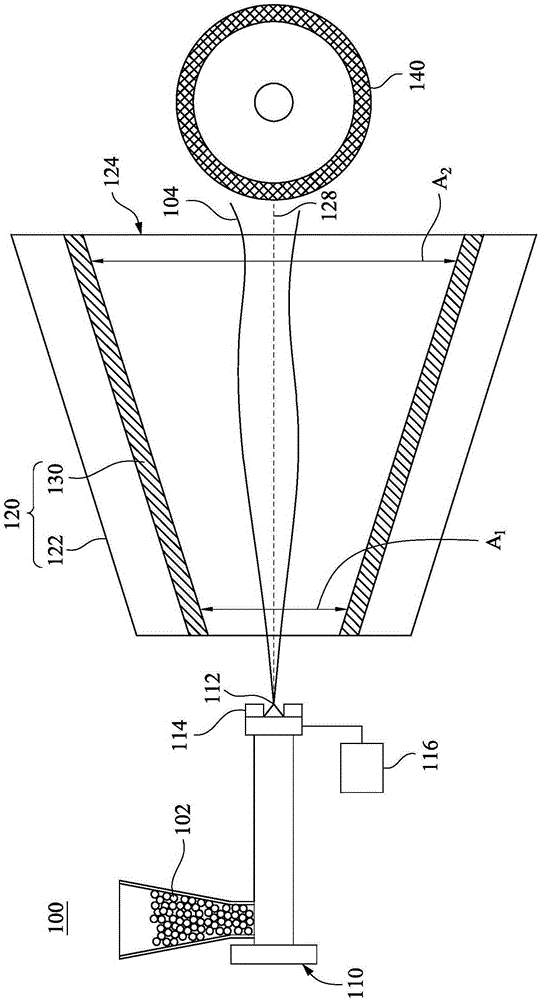

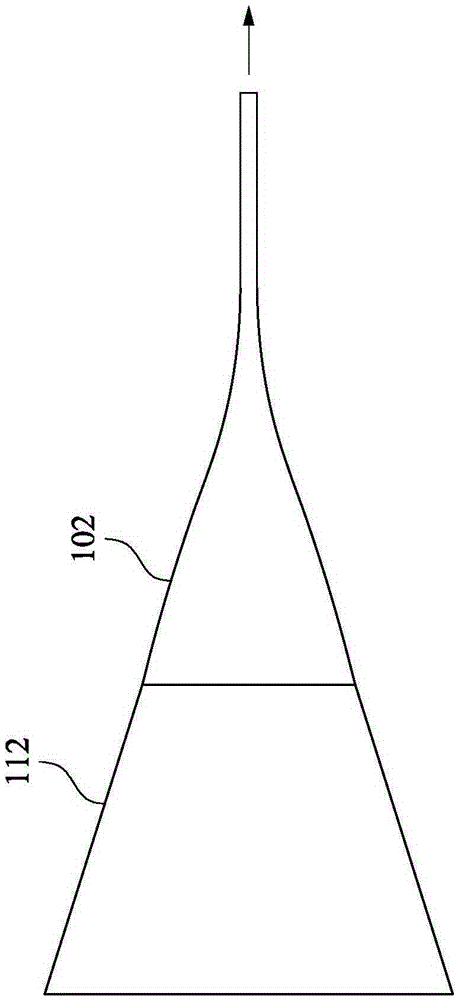

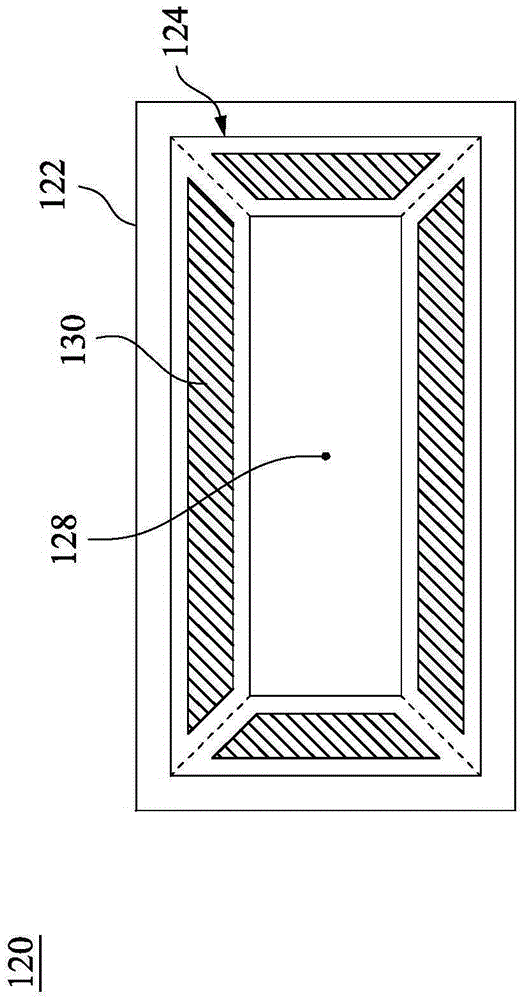

[0036] The following is a detailed description of the embodiments in conjunction with the accompanying drawings, but the provided embodiments are not intended to limit the scope of the present invention, and the description of the structure and operation is not intended to limit the order of execution, and any recombination of components The structure of the resulting device with equal efficacy is within the scope of the present invention. In addition, the drawings are for illustrative purposes only and are not drawn to original scale. For ease of understanding, the same components will be described with the same symbols in the following description.

[0037] As used herein, "about", "approximately" or "approximately" generally means that the error or range of the value is within about 20%, preferably within about 10%, and more preferably It is within about five percent. If there is no explicit statement in the text, the numerical values mentioned in it are regarded as app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com