Anti-mosquito and fly repellent microcapsule finishing agent and its preparation method and application

A technology of microcapsule finishing and microcapsules, which is applied in fiber processing, textiles and papermaking, plant fibers, etc., can solve the problems of poisonous and low mosquito repellent finishing technology, and achieve excellent mosquito repellent effect. , Improve the durability and washability, the effect of fresh smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

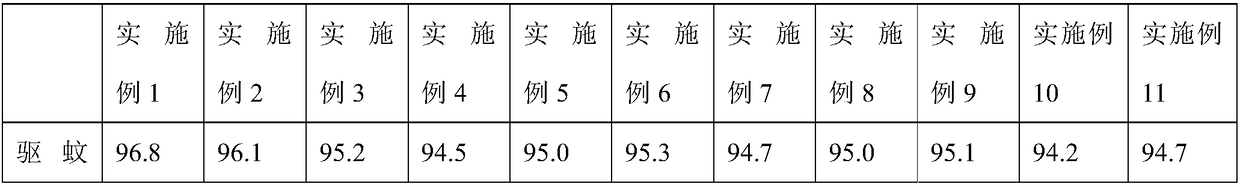

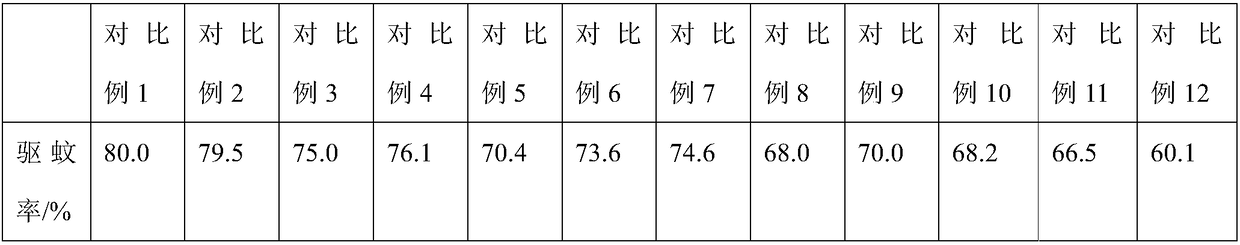

Examples

Embodiment 1

[0050] An anti-mosquito and fly-repelling microcapsule finishing agent is composed of the following components according to mass percentage:

[0051] 23% of the anti-mosquito and fly-repelling microcapsules, 12% of water-based polyurethane, and the rest are deionized water. 1:1.5. Its preparation method is:

[0052] (1) Prepare the anti-mosquito and fly-repelling microcapsules, the specific operations are:

[0053] (a) cyclodextrin is dissolved in the acetic acid solution that mass concentration is 2% and is made into cyclodextrin-acetic acid solution that mass fraction is 4.5%; Polylysine is dissolved in water and is made into poly Lysine-aqueous solution; dissolving sodium caseinate in water to form a 2% sodium caseinate-aqueous solution by mass fraction;

[0054] (b) Take cyclodextrin-acetic acid solution and polylysine-water solution and stir and mix evenly to form a wall material compound solution, wherein the mass ratio of cyclodextrin and polylysine is 1:2;

[0055]...

Embodiment 2

[0061] Compared with Example 1, the mass percentage of the anti-mosquito and fly-repelling microcapsules is 20%, the mass percentage of water-based polyurethane is 6%, and the others are the same as in Example 1.

Embodiment 3

[0063] Compared with Example 1, the mass percentage of the anti-mosquito and fly-repelling microcapsules is 22%, the mass percentage of water-based polyurethane is 8%, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com