Water permeable ground system and paving method

A ground system and water-permeable technology, applied to pavement details, roads, gutters/curbs, etc., can solve problems such as water-permeable ground failure, and achieve low maintenance costs and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

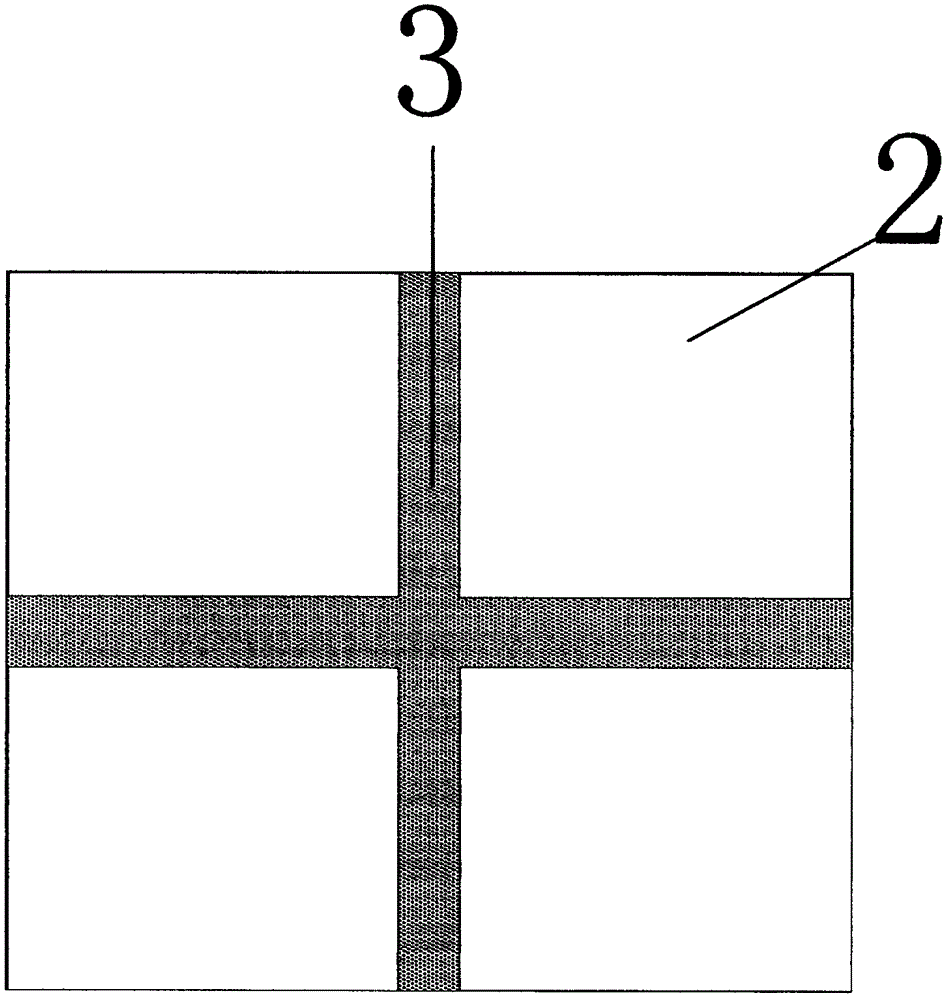

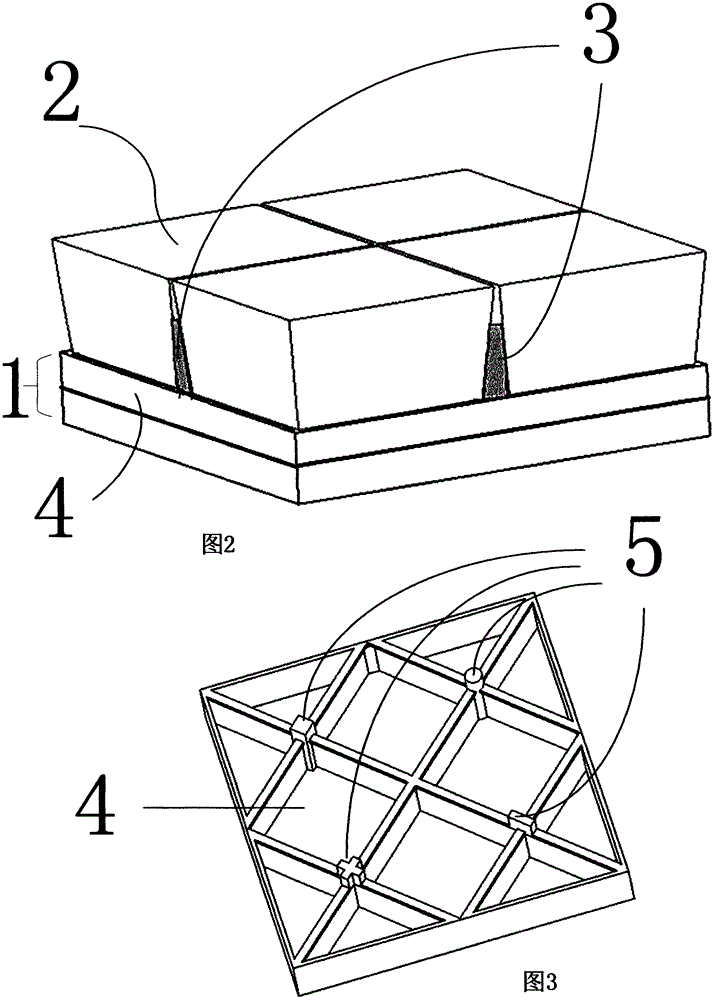

[0046] figure 1 It is a top view of a permeable ground system provided by an embodiment of the present invention. like figure 1 and figure 2 As shown, the permeable surface layer of a permeable floor system provided in this embodiment includes a plurality of permeable bricks 2 and a plurality of permeable strips 3;

[0047] like image 3 As shown, the upper part of the fixed grid 4 has an upwardly protruding fixed post 5 . The shape of the fixed column 5 can be a cylinder, a square column, a strip, a cross, etc., and is not limited to its specific shape.

[0048] Understandably, image 3 For the 4 grid cells in , the shape of the fixed column is different from each other to illustrate that the fixed column can have different shapes. In most cases, the fixed column shapes of each grid cell in the same fixed grid are the same.

[0049] like Figure 11 , as shown in 12, 13, and 14, corresponding to each fixing column 5, an upwardly recessed fixing groove 6 is provided at t...

Embodiment 2

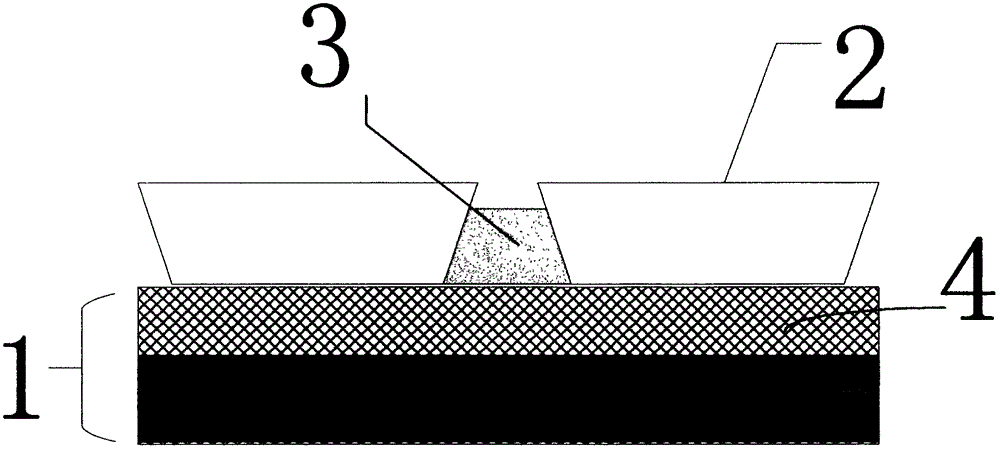

[0060] like Figure 5 As shown, this embodiment is similar to Embodiment 1, the difference is that the cross-sectional shape of the permeable strip 3 is an inverted T shape, and the edge of the permeable brick 2 is also changed accordingly to match the shape of the permeable strip, forming a structure with a narrow top and a wide bottom, which is convenient for water permeability Bar 3 is firmly clamped in the gap.

[0061] In this embodiment, the outer edge of the bottom surface of the permeable brick 2 (the surface in contact with the permeable base 1 ) is hollowed out to form a concave structure with a rectangular cross section, so that the cross section of the permeable brick 2 is T-shaped. Correspondingly, a slot with an inverted T-shaped cross section is formed between two adjacent permeable bricks 2, and the cross-sectional shape of the permeable strip 3 matches the inverted T-shaped slot, so that the permeable strip It can be tightly buckled in the card slot.

[0062...

Embodiment 3

[0064] See Image 6 , this embodiment is similar to Embodiment 1, the difference is that the cross-sectional shape of the permeable strip 3 is rectangular, and the edge of the permeable brick 2 is also changed accordingly to match the shape of the permeable strip, forming a structure with a narrow top and a wide bottom, which is convenient for the permeable strip 3 to be firmly locked set in the gap.

[0065] In this embodiment, the depth of the shallow groove formed on the surface of the permeable strip 3 is the height of the permeable brick 2 minus the height of the concave structure formed at the outer edge of the bottom surface of the permeable brick 2 .

[0066] It can be understood that when two permeable strips 3 intersect, they can be tailored to match the specific environment on site, or a specific intersection shape can be customized as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com