Construction method for underground large-span large-space ultrahigh non-column steel structural tube truss

A technology of pipe truss and large space, which is applied in the field of construction method of underground large-span and large-space super-high column-free steel structure pipe truss, which can solve the problem that the whole truss cannot be directly transported to the site, does not have the conditions for docking and hoisting equipment, and cannot be directly transported by a single truss. Hoisting in place and other issues to achieve good development prospects, reduce instability, facilitate popularization and application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] see Figure 1 to Figure 11 , an underground large-span large-space ultra-high column-free steel structure pipe truss construction method, the following steps are adopted:

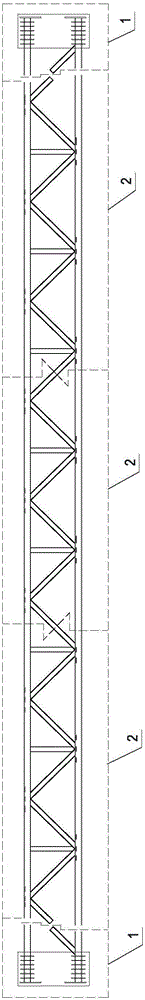

[0024] 1) Divide each pipe truss into two structurally symmetrical truss end parts 1 and 2 to 4 truss unit bodies 2, and complete the prefabrication of all the truss end parts 1 and all the truss unit bodies 2 in the factory.

[0025] 2) On the construction site, pre-embed the end 1 of the truss on the set permanent structure 7 .

[0026] 3) At the construction site, the truss unit body 2 is transported to the right below the set installation position by a gun truck, and it is located on the sleeper, and then two adjacent truss unit bodies 2 are connected together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com