Double-speed variable-torque drill bit for drilling deep well

A drill bit, quick-change technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of drill bit wear, uneconomical, high cost, and achieve the effect of improving crushing efficiency and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

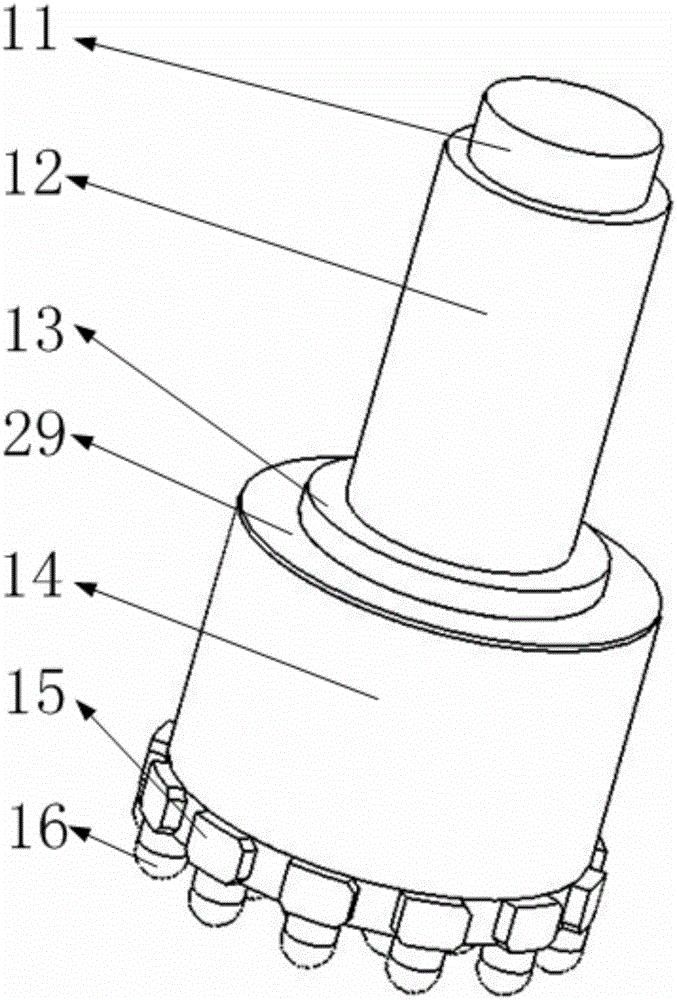

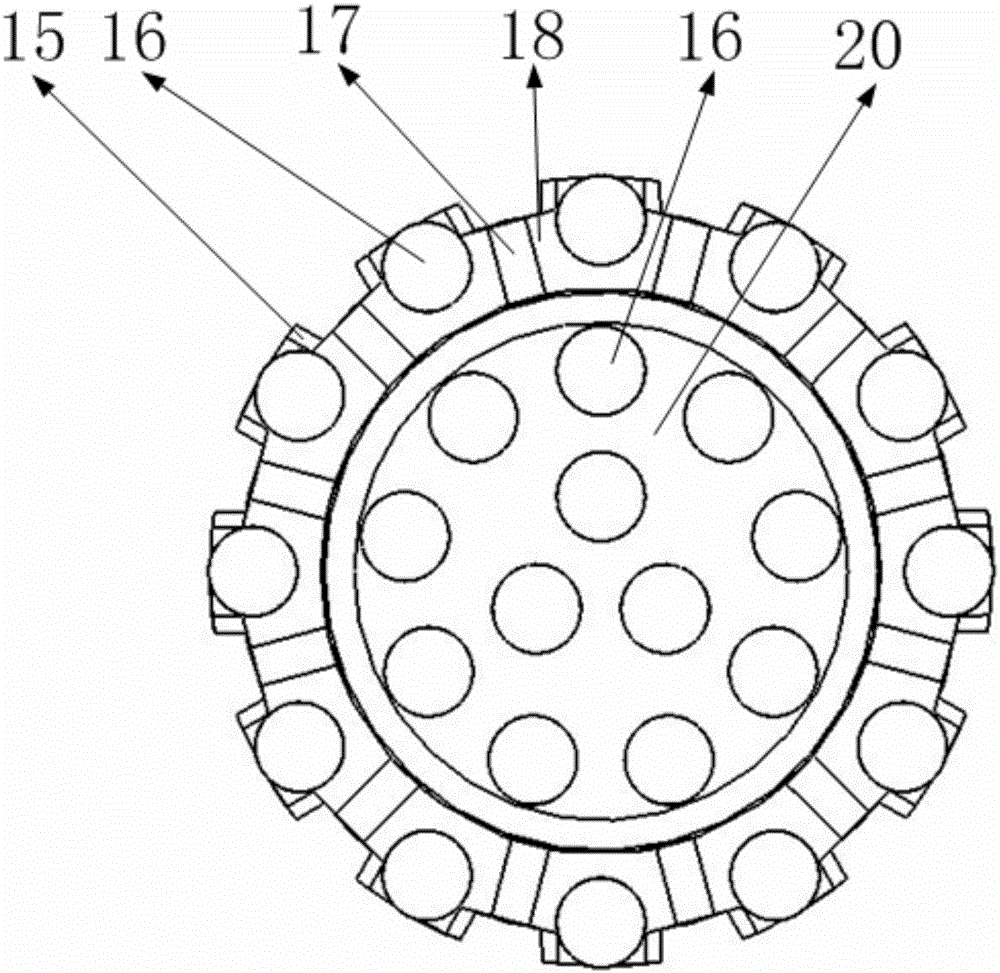

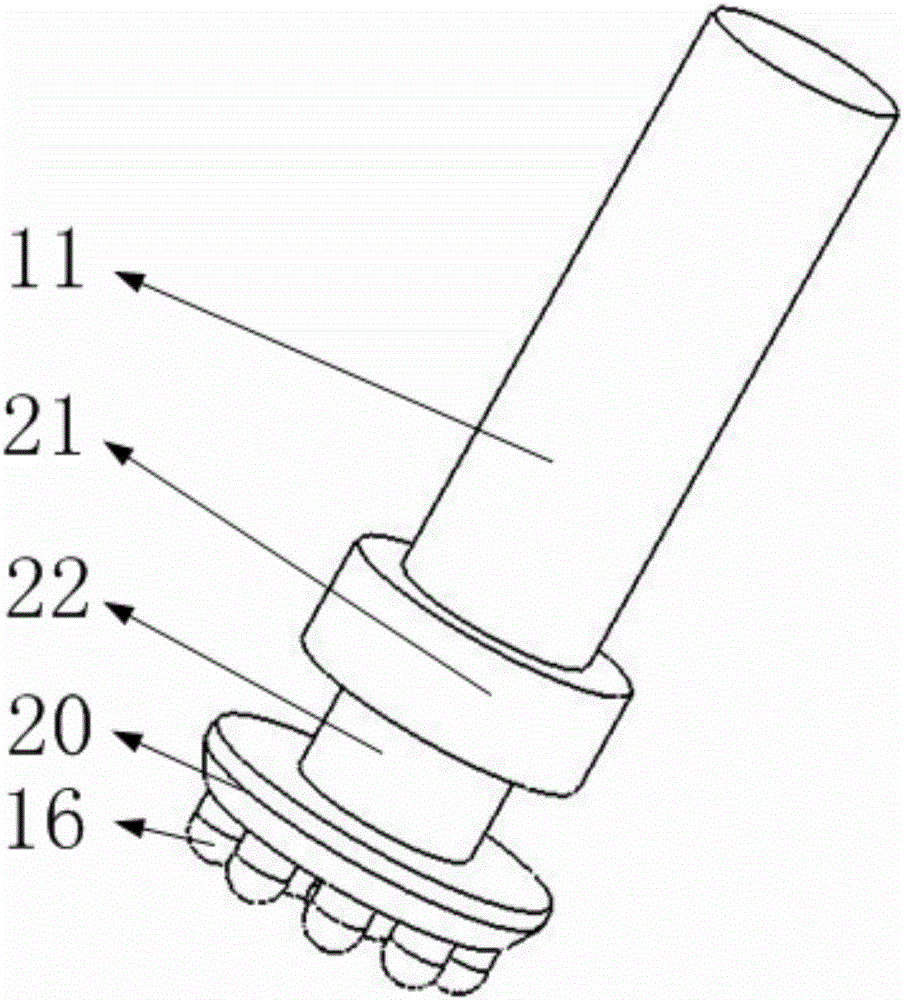

[0022] Such as figure 1 , 10 As shown, it includes drill rod, fixed rod sleeve, first planetary support plate, drill ring support, drill ring side cutting head, drilling head, drill ring, center drill disc, hydraulic torque converter, drill inner rod, Inner gear ring, planetary gear, planetary gear shaft, second planetary support plate, drill ring support bearing, among which image 3 As shown, the input end of the hydraulic torque converter is connected to the drill rod, the output end of the hydraulic torque converter is connected to the inner rod of the drill bit, and the upper side of the center drill disc is installed on one end of the inner rod of the drill bit, as shown in image 3 , 4 As shown, there are multiple drilling heads installed on the underside of the central drilling disc; Figure 7 As shown, the fixed rod sleeve is nested on the outside of the drill bit, the first planetary support plate is installed at the lower end of the fixed rod sleeve, and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com