Mechanically adjustable intake and exhaust diversion system of exhaust air heat countercurrent oxidation device

A technology of countercurrent oxidation and mechanical adjustment, which is applied in the direction of safety devices, mining devices, gas discharge, etc., and can solve the problems affecting the cross-sectional flow and temperature field balance of the reaction chamber, the deflector angle cannot be flexibly adjusted, and poor adaptation. To achieve the effect of stable and reliable thermal oxidation process, balanced and continuous distribution of air intake, and good temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

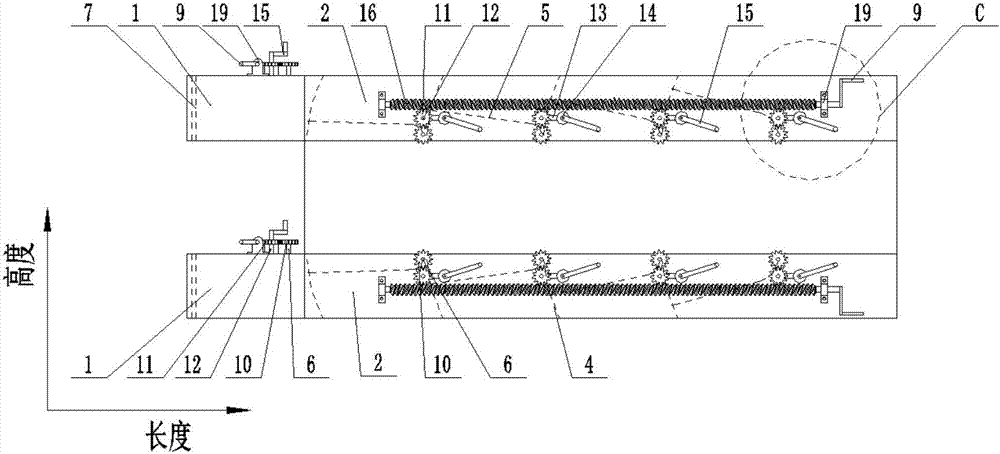

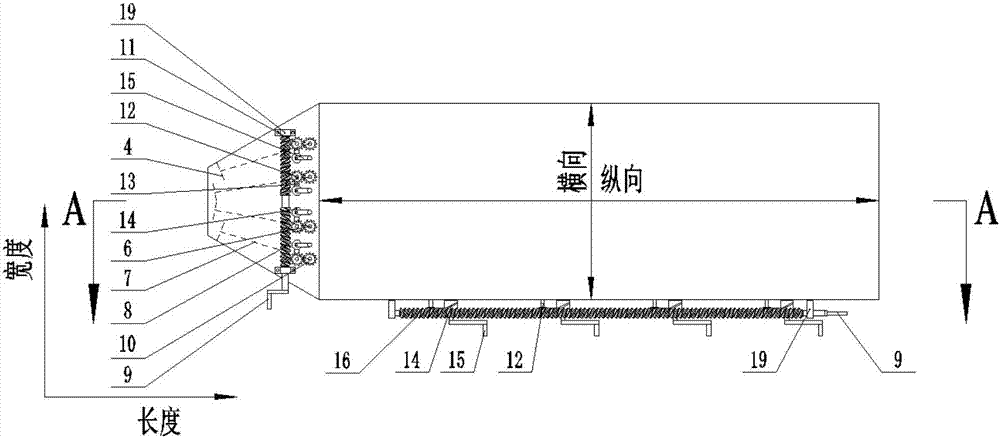

[0028] The present invention will be further described below in conjunction with the accompanying drawings. exist Figure 1-7 In the example shown:

[0029] The upper and lower sides of the reaction chamber 3 are respectively provided with an intake and exhaust chamber 2, the reaction chamber 2 communicates with the intake and exhaust chamber 2, and the opening end of each intake and exhaust chamber 2 communicates with the expansion section 1 of the intake and exhaust port. A plurality of arc-shaped guide rails 4 and first deflectors 5 are evenly distributed in each intake and exhaust cavity 2, and the movable end of each first deflector 5 is correspondingly connected with an arc-shaped guide rail 4, and the first deflector The other end of 5 is provided with a fixed shaft 6 in the horizontal direction, and both ends of the fixed shaft 6 pass through the side walls of the intake and exhaust chambers 2; each intake and exhaust chamber 2 is provided with four first deflectors 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com