Bypass starting system and starting method of combined cycle extraction condensing and back pressure unit

A technology of back pressure unit and combined cycle, which is applied in the steam generation method using heat carrier, combined engine, machine/engine, etc., can solve problems such as loss of steam working medium, environmental noise pollution, influence, etc., to ensure safety start effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

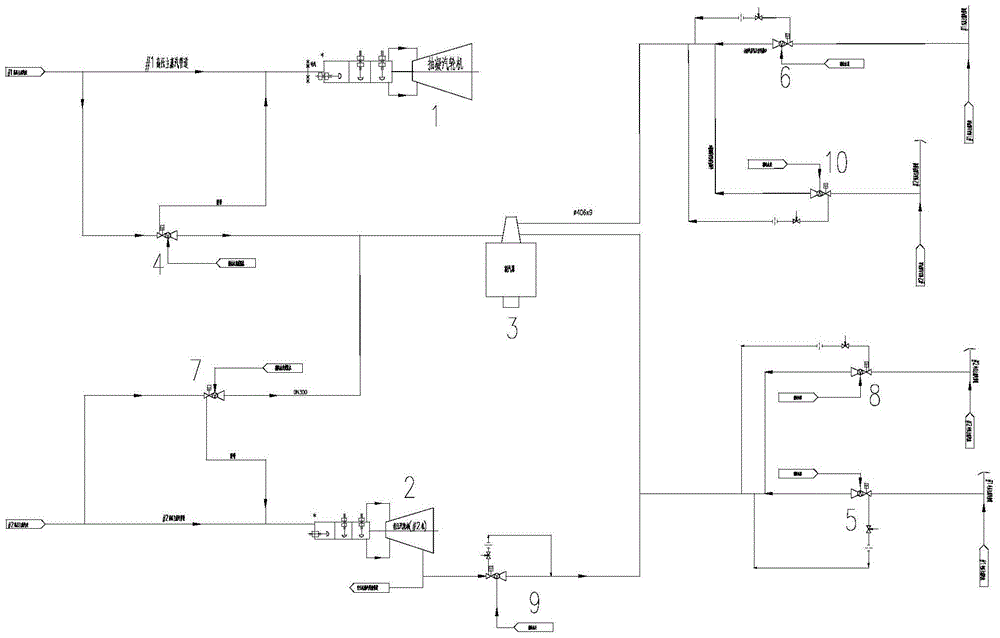

[0016] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a start-up bypass system of a combined cycle condensing and back-pressure unit according to the present invention mainly includes: an extraction condensing steam turbine unit 1, a back-pressure steam turbine unit 2, and a condenser 3. The extraction condensing steam turbine unit 1 and the back pressure steam turbine unit 2 are equipped with the same waste heat boiler capacity, and the extraction condensing steam turbine unit 1 is provided with a condenser with a capacity of 100% of the waste heat boiler steam; the extraction condensing steam turbine When the group is in the maximum steam extraction condition, the condenser can accommodate the amount of steam produced when the back pressure steam turbine unit 2 starts; the extraction condensing turbine unit 1 is provided with three bypasses, including the 100% combustion Engine load high pressure bypass 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com