Efficient garbage processing method

A treatment method and high-efficiency technology, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of secondary pollution of groundwater, large air pollution, and large area, achieve cost savings, improve high temperature utilization, Avoid stray effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

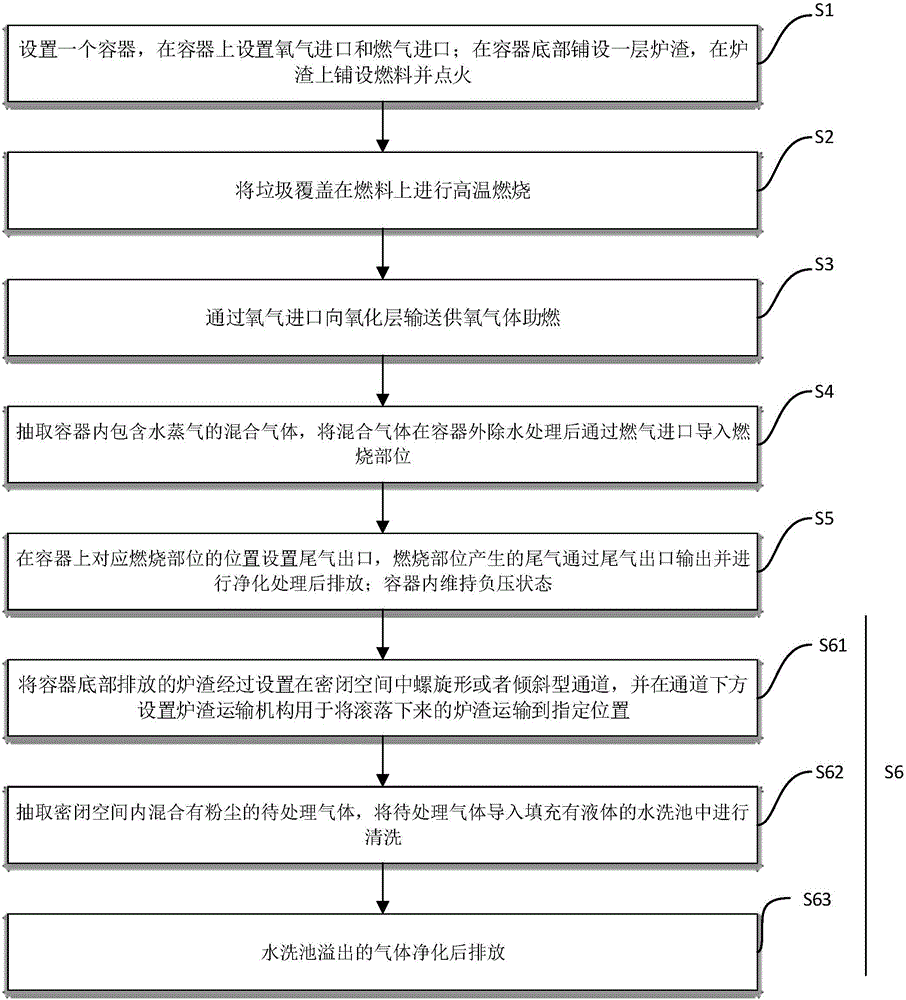

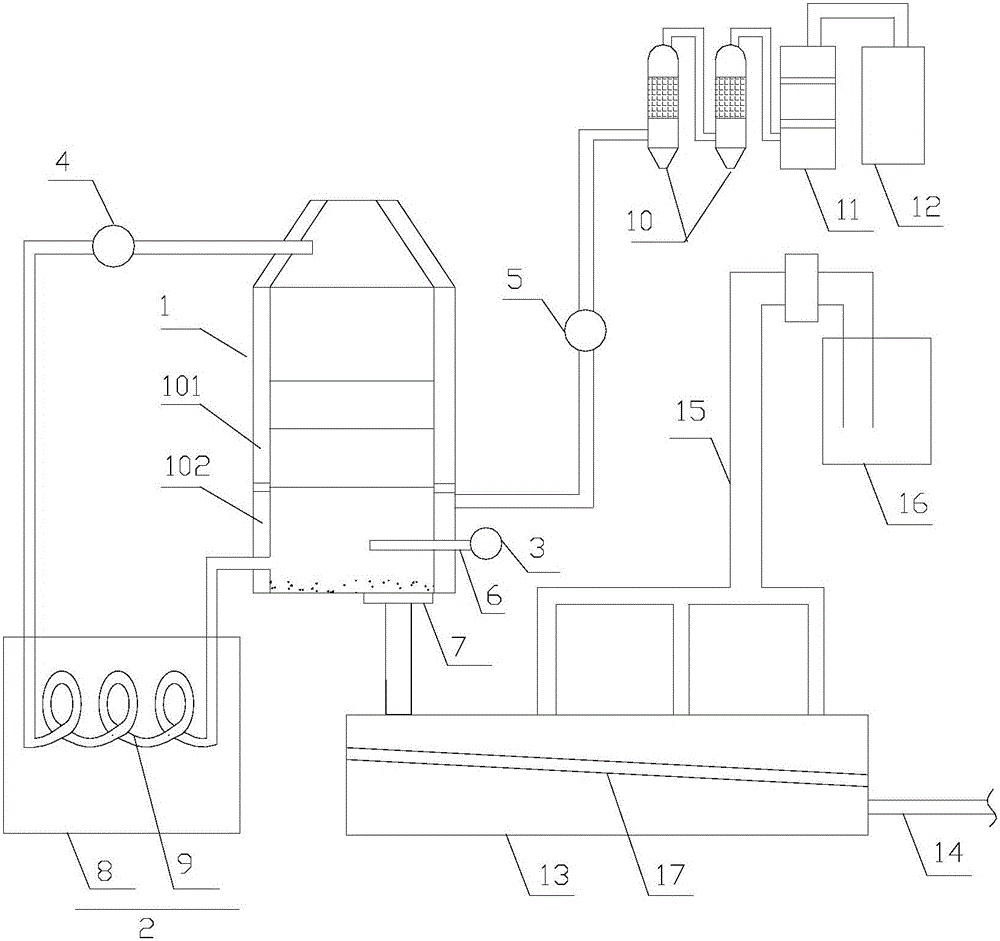

[0028] refer to figure 1 , a kind of high-efficiency garbage processing method proposed by the present invention, comprising the following steps:

[0029] S1. A container is set, and an oxygen supply inlet and a gas inlet are arranged on the container; a layer of slag is laid on the bottom of the container, and fuel is laid on the slag and ignited.

[0030] S2. Cover the garbage on the fuel for high-temperature combustion. The temperature of the garbage gradually decreases from bottom to top, and according to the temperature distribution, the garbage in the container is divided into combustion parts, reduction layers, dry distillation layers and drying layers from bottom to top.

[0031] The garbage in the burning part is burned to generate high temperature, the decomposable substances in the garbage in the reduction layer are decomposed by high temperature and generate combustible gas, the dry distillation layer and the drying layer dehydrate and dry the garbage, and the mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com