Noncontact steering angle sensor

A non-contact technology for angle sensors, applied in the field of sensors, can solve problems such as complex calculation formulas, complex installation and calibration, etc., and achieve the effects of reducing complexity, improving anti-interference ability, and small radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

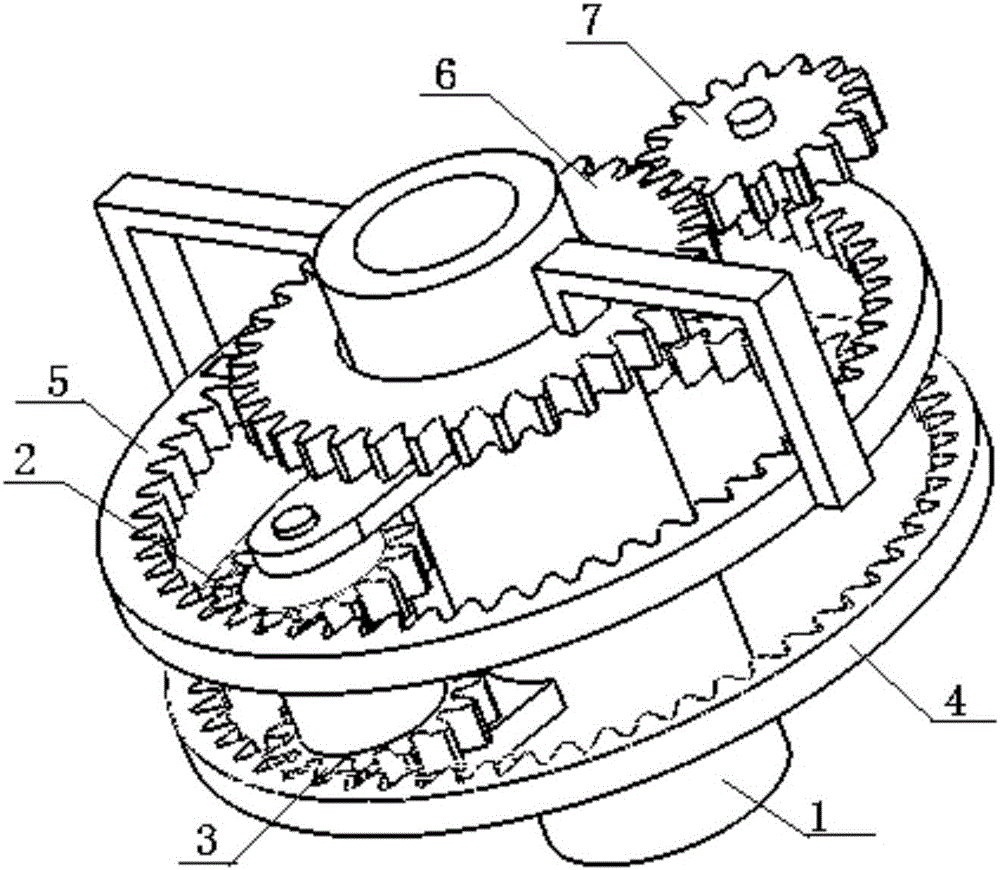

[0029] Such as Figures 1 to 6 As shown, the non-contact angle sensor includes a non-magnetic material housing, and the components installed in the housing include: (1) a sun gear shaft 1 of a non-magnetic material, which is connected to the steering shaft, and at least one set of non-magnetic material is installed on it. The planetary gear set, the planetary gear set is an integral structure, which includes the first planetary gear 3 and the second planetary gear 2; (2) the fixed inner ring gear 4 of non-magnetic material, which is coaxial with the sun gear shaft 1, and is fixed on the casing or It has an integral structure with the shell; (3) the transmission wheel set of non-magnetic material, the transmission wheel set is an integral structure, which is installed coaxially with the sun gear shaft 1, including the transmission inner gear ring 5 and the transmission gear 6; (4) the measurement component, It includes a measuring gear 7 of non-magnetic material, a magnet 8 and...

Embodiment 2

[0032] The structure of embodiment two is basically the same as that of embodiment one, the difference is:

[0033] The sum of the teeth of the fixed internal gear ring and the second planetary gear is equal to the sum of the teeth of the transmission internal gear ring and the first planetary gear. The coaxiality of the two planetary gears and the two inner gear rings is ensured, and at the same time, the radial size of the inner gear rings is reduced to reduce the volume of the sensor.

Embodiment 3

[0035] The structure of embodiment three is basically the same as that of embodiment one, the difference is:

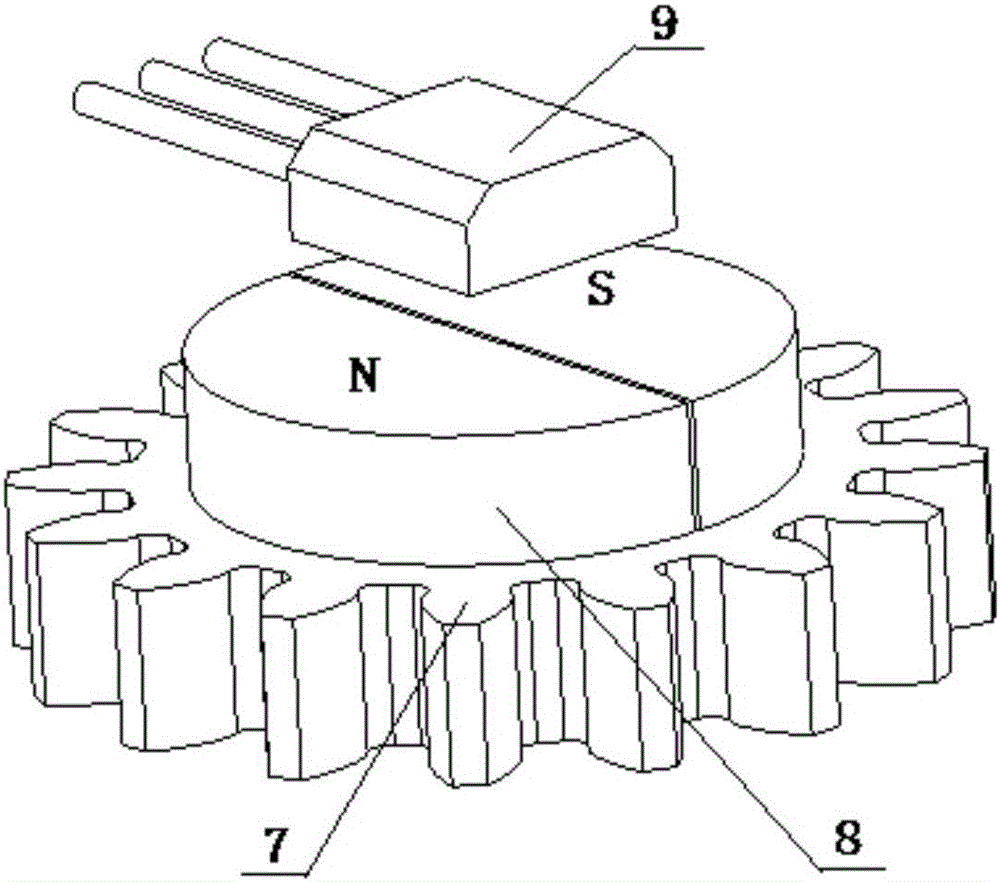

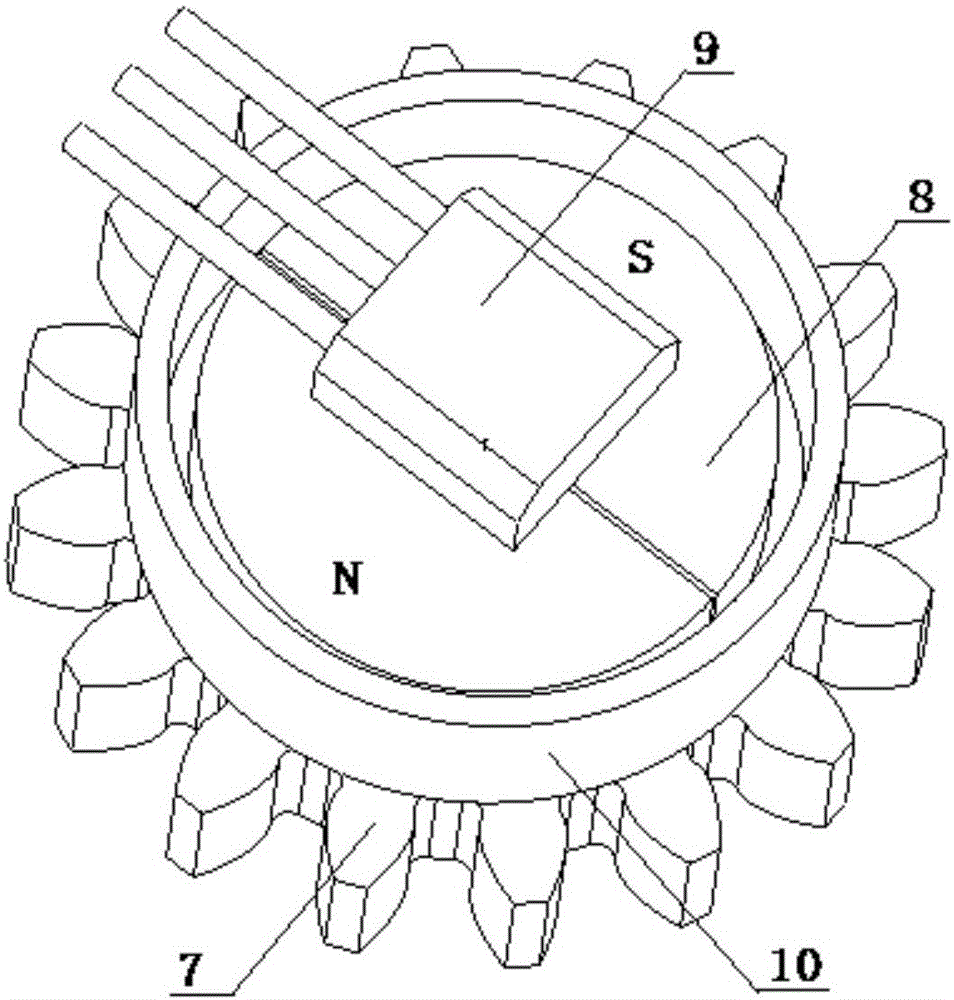

[0036] At least one magnet 8 is installed on the axial surface of the measuring gear 7, and at least one magnetic induction element 9 is installed above the magnet 8, and the magnetic induction element 9 is fixed in the housing of the sensor, leaving a certain gap between the magnet 8 and the magnetic induction element 9.

[0037] The magnetic force line passing through the magnetic induction element 9 starts from the N-level of the magnet 8, passes through the gap between the N-level of the magnet 8 and the magnetic induction element 9, passes through the magnetic induction element 9, and passes through the gap between the magnetic induction element 9 and the S-level of the magnet 8 The gap reaches the S level of the magnet 8, and finally the S level of the magnet 8 reaches the N level of the magnet 8 through the gap between the S level and the N level of the magnet 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com