Short-sonic-path, ultrasonic and non-destructive probe for surface residual stress of large-curvature member

A technology of residual stress and components, which is applied in the direction of material analysis, force measurement, force/torque/power measuring instrument using sound wave/ultrasonic wave/infrasonic wave, and can solve the problem of single curvature of measurement surface, decrease of detection efficiency, subjective influence of movement accuracy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in detail below:

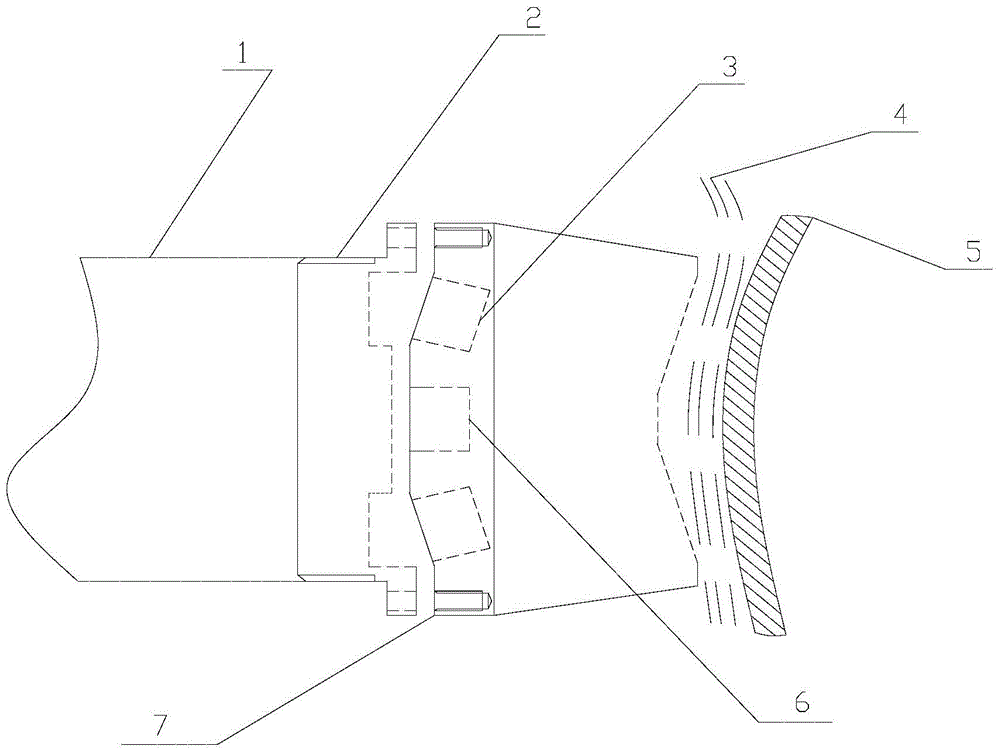

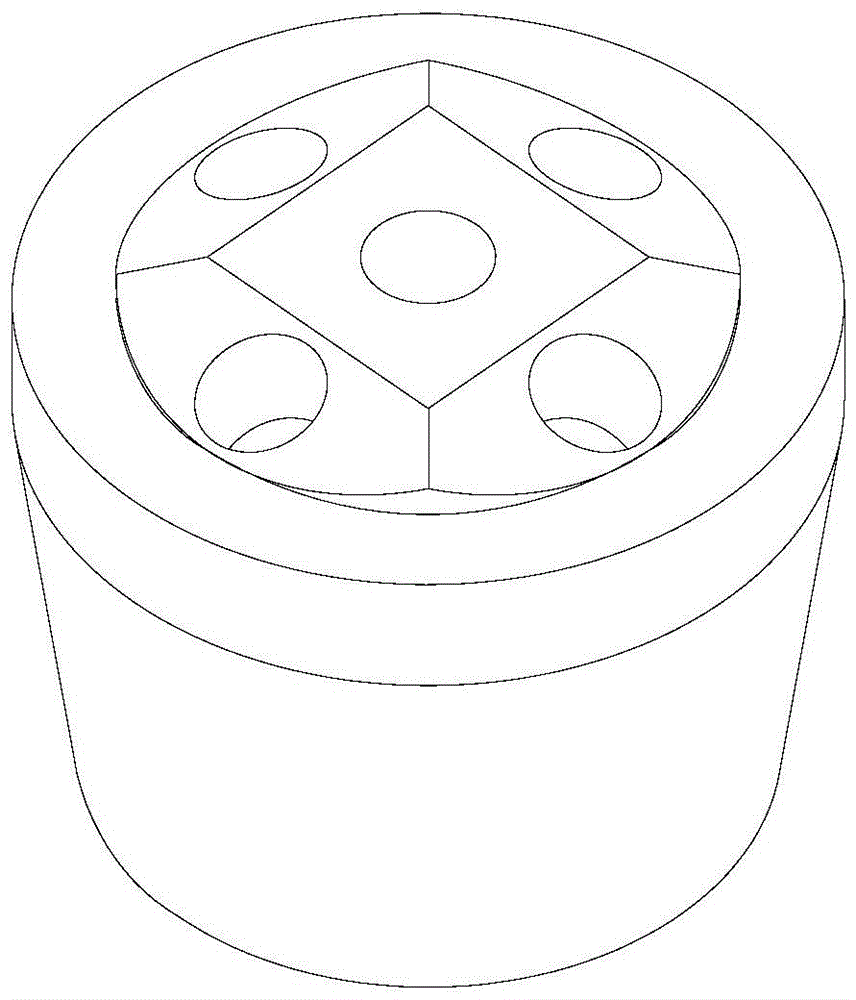

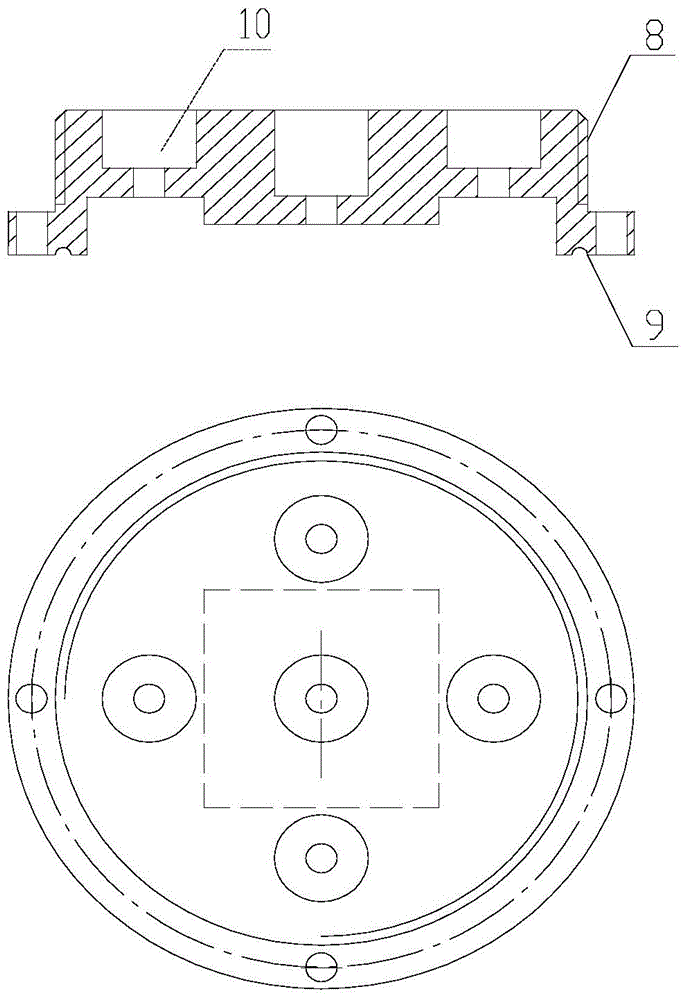

[0012] figure 1 It is a schematic diagram of ultrasonic detection of blade surface residual stress, including plexiglass wedge 7 ( figure 2 ), capping ( image 3 ), ranging piezoelectric wafer 6, and detecting stress piezoelectric wafer 3.

[0013] When detecting residual stress on the surface of the detection component, the sensor must be fixed on the movable fixed frame through the thread on the cover, and then immersed in water. At the same time, the component to be detected is also immersed in water, and by effectively controlling the movable device, an appropriate distance between the sensor and the component to be detected is always maintained. Then the other two groups of piezoelectric chips sequentially excite ultrasonic waves to generate critical refracted longitudinal waves, and make the generated critical refracted longitudinal waves propagate in a small area of the detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com