Guide rail current collector

A current collector and guide rail technology, which is applied in the field of guide rail collectors, can solve problems such as power failure or shutdown maintenance, parts are easily damaged, and damage to light rail slide lines, etc., to achieve stable operation, reduce local wear, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

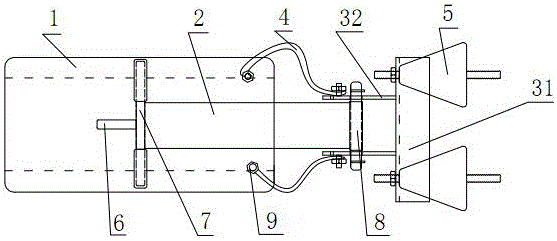

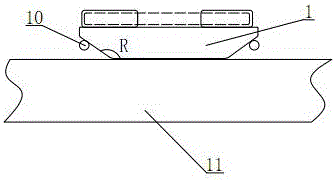

[0030] A conductor rail collector such as Figure 1~3 As shown, it is a one-phase collector in a three-phase power supply, and the three-phase structures are the same. The front end of the conductor rail collector is small, and when sliding on the conductor rail 11, it can all be on the conductor rail 11, and is suitable for vertically arranged conductor rails. The vertically arranged conductive rails are divided into upper, middle and lower rows of three conductive rails, with a spacing of about 500mm. Due to the small spacing, only the collector brush is allowed on the upper part. The connecting plate 2 is perpendicular to the conductive rail 11 to form a vertically installed conductive rail collector.

[0031] The conductor rail collector includes a collector brush 1 arranged on the conductor rail 11 and slidingly matched with the conductor rail 11, a connecting plate mechanism hinged on the collector brush 1, and a fixing frame hinged with the connecting plate mechanism a...

Embodiment 2

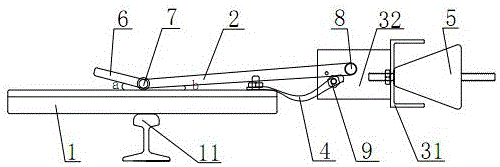

[0040] The difference between this embodiment and embodiment 1 is: as Figure 4 ~As shown in Figure 5, it is a one-phase collector in a three-phase power supply, and the three-phase structure is the same. This is a current collector on one conductive rail 11, the insulating device 5 is connected to the running equipment, and the right side of the running equipment is connected to the current collector on another conductive rail 11. Therefore, all the collectors are located above the conductive rails 11 and occupy a relatively large space, which is suitable for conductive rails arranged in a horizontal line. The connecting plate 2 is parallel to the conductive rail 11, forming a parallel-mounted conductive rail collector.

[0041] when working, such as Figure 4 or Figure 5 As shown, when the present invention slides to the left along the conductive rail 11 following the walking equipment, when a bump or rise appears on the conductive rail 11, the collector brush 1 will rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com