Mold-releasing oil for food baking tray and preparation method of mold-releasing oil

The technology of releasing oil and baking pan is applied in the field of food processing, which can solve the problems of easy precipitation and poor spreadability of releasing oil, and achieves the effects of high safety, improved emulsifying effect and good wall-hanging property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

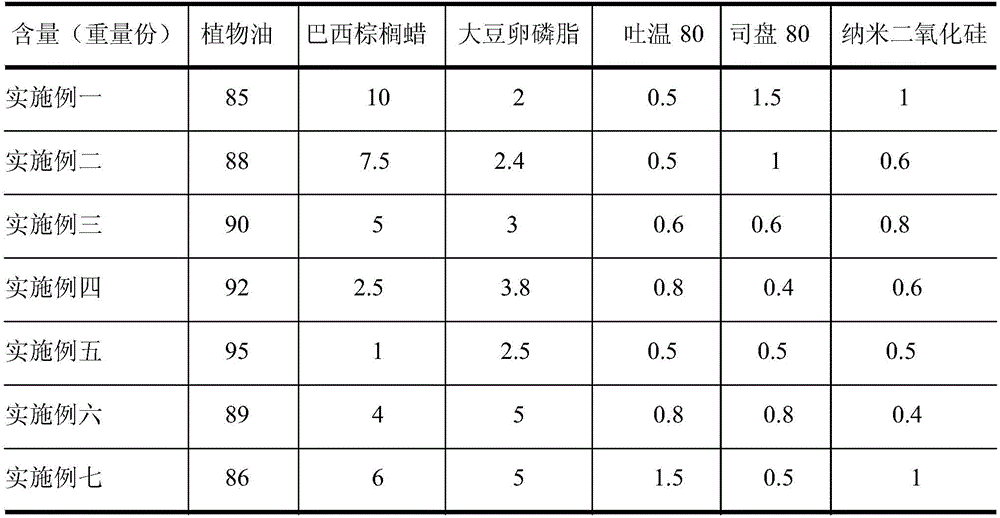

Examples

Embodiment 1

[0020] (1) According to Table 1, each component was dissolved in 85 parts of hot vegetable oil at 90°C, fully stirred and mixed to obtain a uniform mixture;

[0021] (2) Rapid cooling of the mixture obtained in step (1) to below 25°C and kneading;

[0022] (3) The product obtained in step (2) was ultrasonically treated at 500W power for 5min in an ice-water bath;

[0023] (4) Return the temperature of the product in step (3) to above the quenching temperature in step (2), and ripen it to obtain the release oil.

Embodiment 2

[0025] (1) According to Table 1, each component was dissolved in 88 parts of hot vegetable oil at 100°C, fully stirred and mixed to obtain a uniform mixture;

[0026] (2) Rapid cooling of the mixture obtained in step (1) to below 25°C and kneading;

[0027] (3) The product obtained in step (2) was ultrasonically treated at 400W power for 10min in an ice-water bath;

[0028] (4) Return the temperature of the product in step (3) to above the quenching temperature in step (2), and ripen it to obtain the release oil.

Embodiment 3

[0030] (1) Dissolve the components in 90 parts of hot vegetable oil at 105°C according to Table 1, stir and mix thoroughly to obtain a homogeneous mixture;

[0031] (2) Rapid cooling of the mixture obtained in step (1) to below 25°C and kneading;

[0032] (3) The product obtained in step (2) was ultrasonically treated at 350W power for 18min in an ice-water bath;

[0033] (4) Return the temperature of the product in step (3) to above the quenching temperature in step (2), and ripen it to obtain the release oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com