Laser 3D forming process of cavity parts

A forming process and laser technology, applied in the improvement of process efficiency, additive processing, additive manufacturing, etc., can solve the problems of low surface accuracy of the sealing section of the part, low surface accuracy of the part forming, and difficulty in forming the part, so as to eliminate the interference phenomenon. , Good forming effect, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: When the cavity part is not a closed cavity part, that is, when the cavity part does not need to be sealed, the cavity part laser 3D forming process includes the following steps:

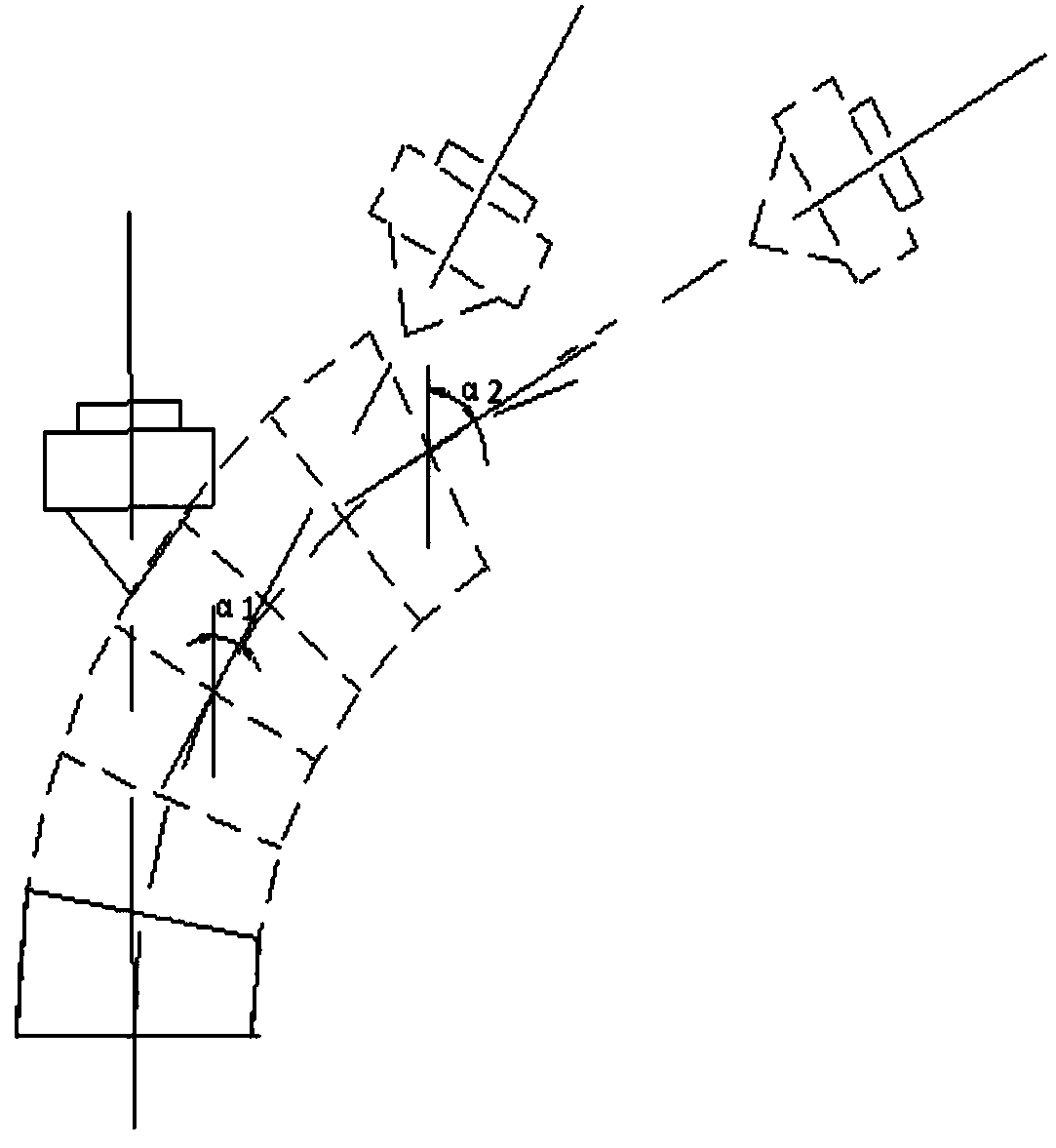

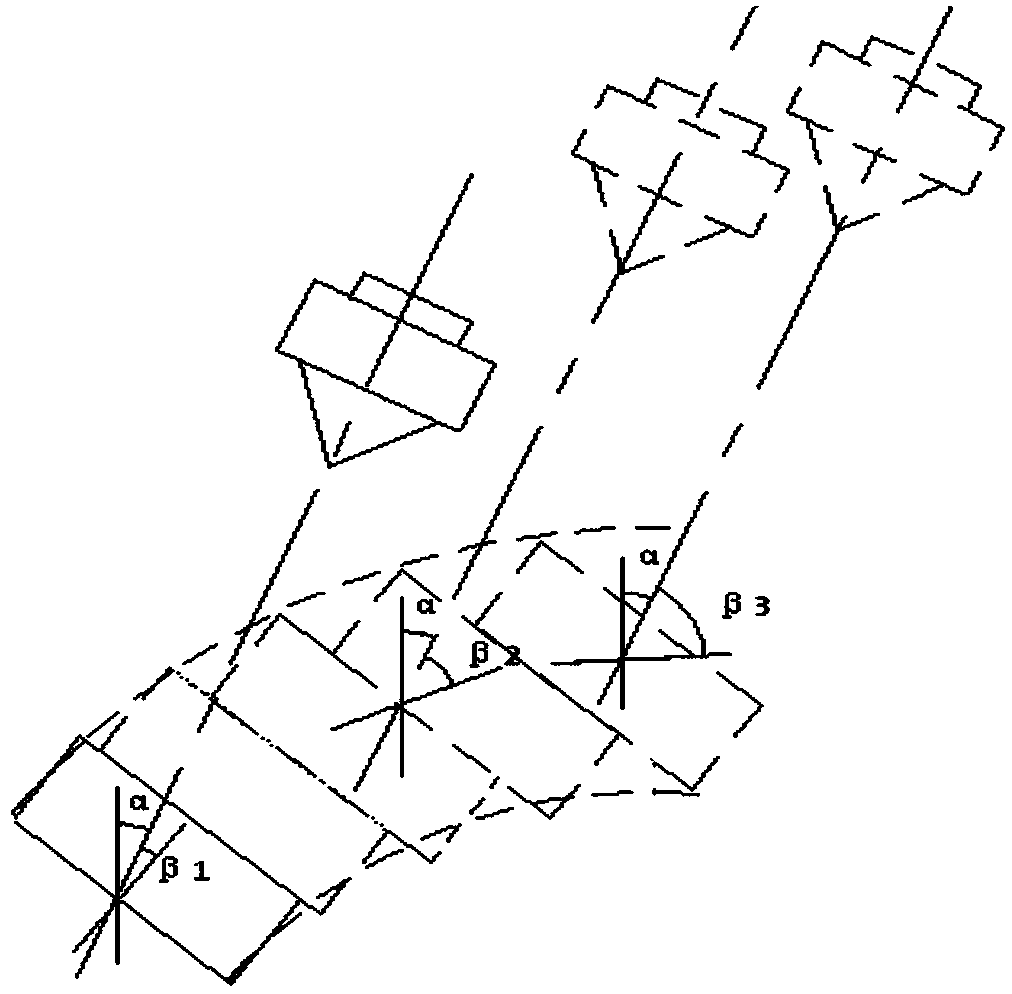

[0028] 1) Establish the three-dimensional geometric model of the cavity part; according to the calculation of whether the lower end of the laser head or the laser beam will interfere with the formed part of the cavity part, the three-dimensional model is divided into a directional forming area and a normal forming area; the lower end of the laser head Or the part where the laser beam will interfere with the formed part of the cavity part is set as the directional forming area, and the rest is the normal forming area;

[0029] 2) The laser optical head adopts the method of feeding powder in the light, and the laser optical head is a ring-conical hollow laser optical head. The laser head emits the laser beam and scans along the preset path; the laser spot combines with the metal p...

Embodiment 2

[0033] Embodiment 2: When the cavity part is a closed cavity part, the laser 3D forming process of the cavity part comprises the following steps:

[0034] 1) Establish the three-dimensional geometric model of the cavity part; according to the calculation of whether the lower end of the laser head or the laser beam will interfere with the formed part of the cavity part, the three-dimensional model is divided into a directional forming area and a normal forming area; the lower end of the laser head Or the part where the laser beam will interfere with the formed part of the cavity part is set as the directional forming area, and the rest is the normal forming area;

[0035] 2) The laser optical head adopts the method of feeding powder in the light, and the laser optical head is a ring-conical hollow laser optical head. The laser head emits the laser beam and scans along the preset path; the laser spot combines with the metal powder sent in to complete the forming of a layer of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com