A Hot Isostatic Pressing Method for Forming Structures with Grain Size Continuously Varying

A grain size, hot isostatic pressing technology, applied in the field of static pressing, can solve problems such as inability to manufacture parts, and achieve the effect of eliminating the step effect, the change of performance is continuous and stable, and the operability and applicability are strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Schematic diagram of the process flow for preparing Ti alloy cylindrical parts with a continuously changing structure of grain size, which specifically includes the following steps:

[0037] (1) Obtain Ti alloy powder particles with different particle sizes by using plasmaization and other pulverization methods.

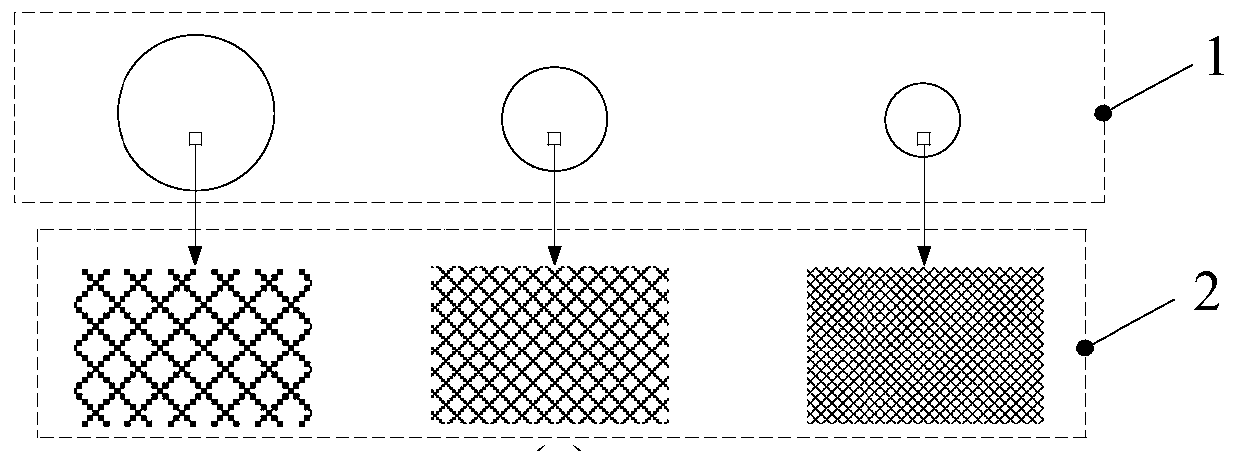

[0038] like Figure 1a As shown, during the milling process, the powder particle size usually has several characteristics of random distribution, normal distribution or lognormal distribution. Since powder particles 1 vary in size, their grain size 2 also varies. Usually, the powder with small particle size has fine grains due to fast cooling; while the large particle size has coarse grains due to slow cooling.

[0039] (2) According to the part model, design the three-dimensional CAD model of the bag and process it into shape.

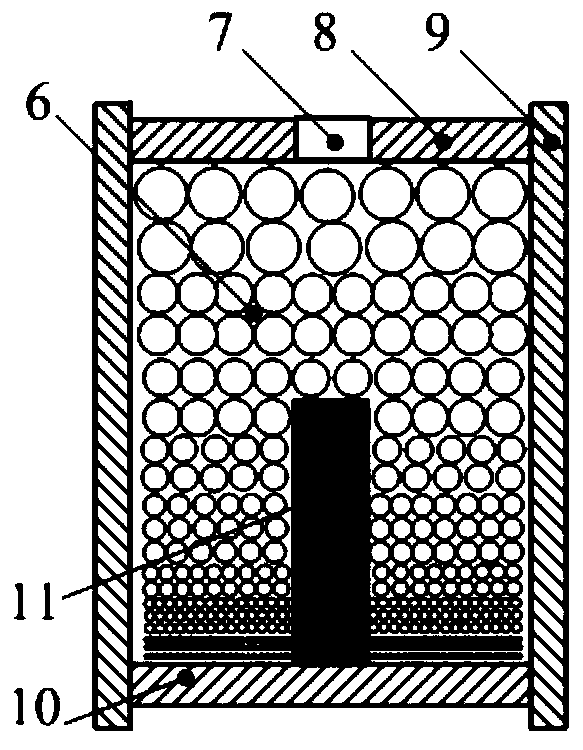

[0040] The sheath usually consists of a cylinder body 9, an upper end cap 8, a lower end cap 10 and a core 11, wherein the upper a...

example 2

[0052] Schematic diagram of preparing a Ti alloy cylindrical part with a continuously changing grain size structure. The basic steps are the same as in Example 1, but the process is adjusted during the vibration application process to obtain a different grain size distribution structure. Specifically, the following steps are included:

[0053] (1) Obtain Ti alloy powder particles with different particle sizes by using plasmaization and other pulverization methods.

[0054] (2) According to the part model, use the 3D modeling software to design the 3D model of the bag and process and assemble it.

[0055] (3) Fill the sheath with random, normal or lognormal distribution of particle size powder, and apply high-frequency vibration to make the powder form particle size segregation and continuous layering in the sheath.

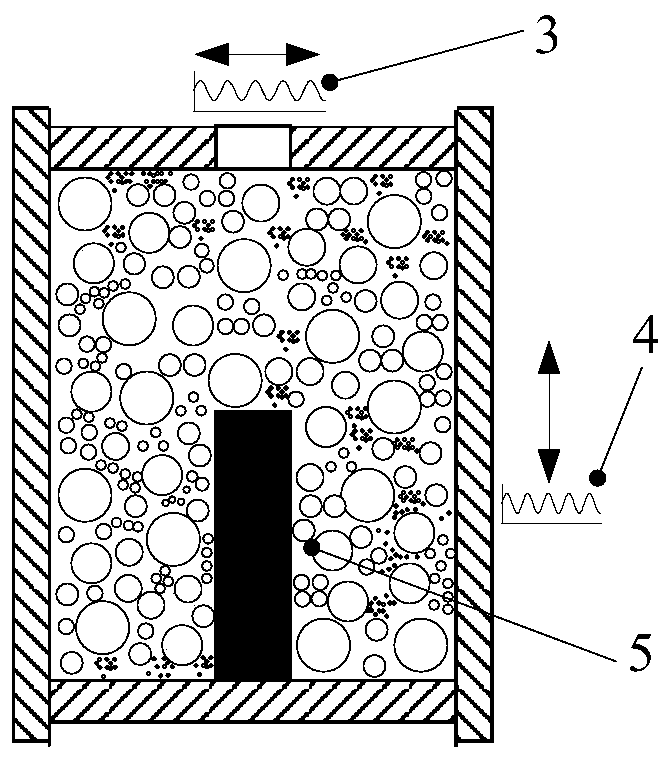

[0056] like Figure 2a As shown, in this example, specific segregation and stratification effects are obtained by adjusting the frequency, amplitude, phase, and ...

example 3

[0063] Schematic diagram of preparing Ni alloy casing parts with continuously changing structure of grain size. The basic steps are the same as in Example 1, but the specific wrapping structure of the casing parts is changed. In addition, the process is adjusted in the vibration application process, and different results are obtained. The grain size distribution structure specifically comprises the following steps:

[0064] (1) Obtain Ni alloy powder particles with different particle sizes by using plasmaization and other pulverizing methods.

[0065] (2) According to the model of the casing parts, the three-dimensional model of the casing is designed and assembled by using three-dimensional modeling software.

[0066] (3) Fill the sheath with random, normal or lognormal distribution of particle size powder, and apply high-frequency vibration to make the powder form particle size segregation and continuous layering in the sheath.

[0067] like Figure 3a As shown, in this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com