Automatic sorting and packaging method for plate-shaped materials in multiple mixed orders and control system thereof

A technology of automatic sorting and packaging methods, applied in the direction of automatic packaging control, packaging, packaging machines, etc., can solve the problems that the packaging system cannot be automatically sorted, the packaging system cannot be normal packaging, etc., to achieve intelligent automatic operation, The effect of improving sorting and packaging efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

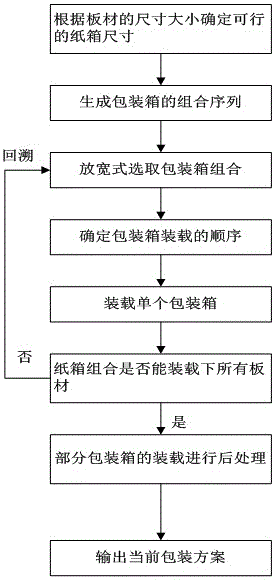

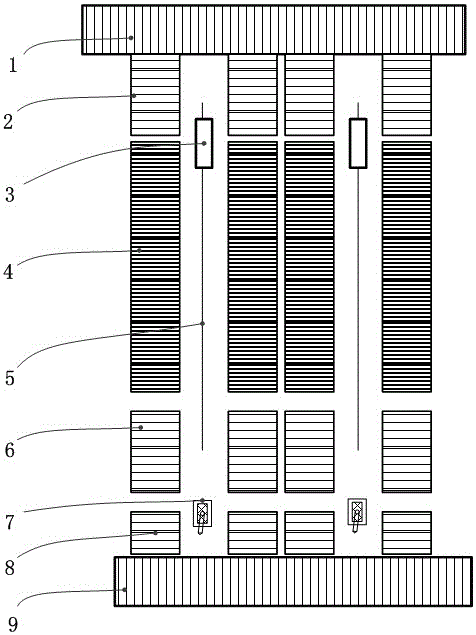

[0063] A method for automatic sorting and packaging of plate-shaped materials with multiple orders mixed, such as figure 1 and figure 2 shown, including the following steps:

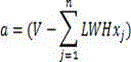

[0064] Step A: the step of generating an initial packaging scheme; using a three-dimensional packing algorithm to output the current packaging scheme for the plate-shaped material; initially generating a packaging scheme according to multiple initial orders or batches of plate-shaped materials. Before the plate-shaped material is produced or processed, the orders and batches of the plate-shaped material are provided by the customer or the demand department of the enterprise, so a single order or the same batch of plate-shaped material can be preliminarily generated into a packaging plan before production or processing , tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com