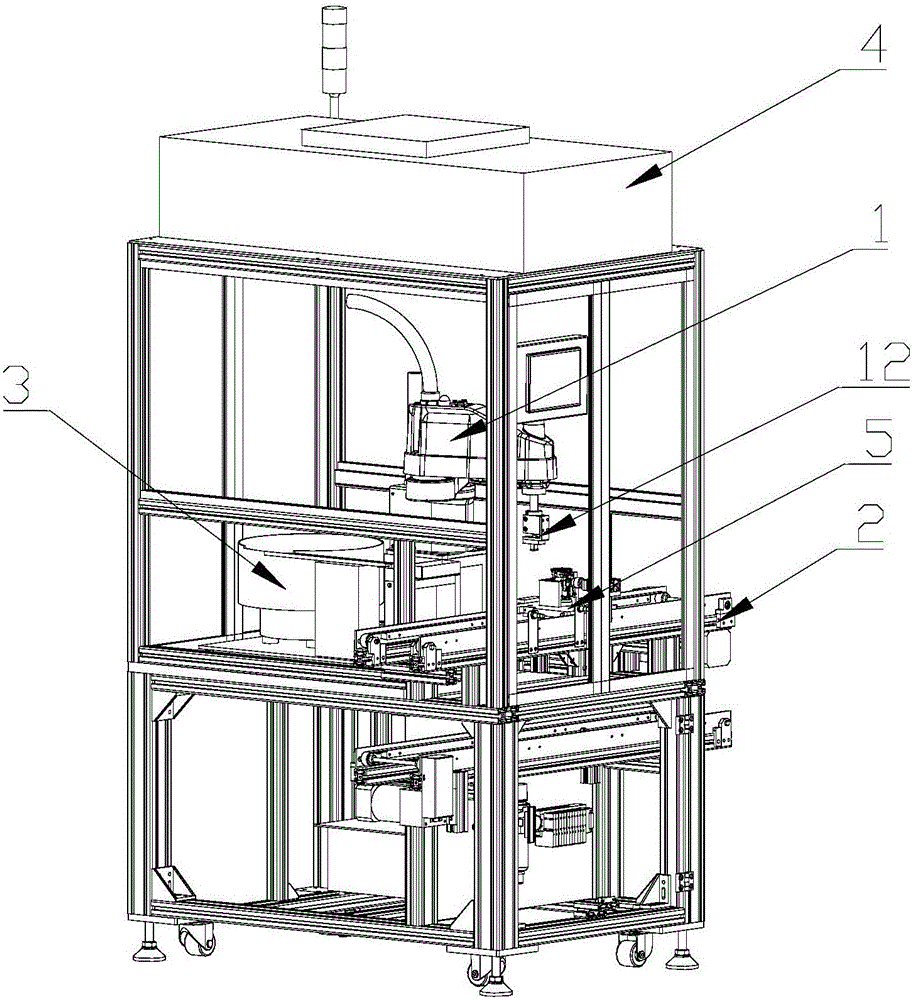

Continuous feeding assembly machine for rubber mat of all-in-one machine movement

An all-in-one machine and assembly machine technology, applied in the direction of conveyors, vibrating conveyors, conveyor objects, etc., can solve problems such as high labor intensity, laborious work, light leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

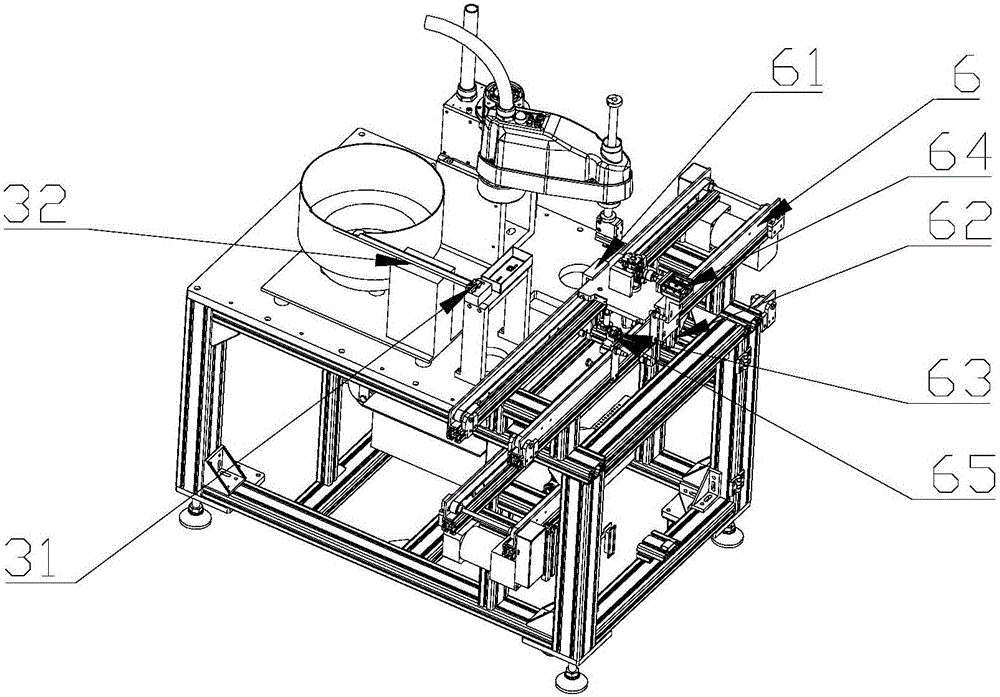

[0024] As a preferred embodiment of the present invention, the feeding mechanism 3 is provided with a vibration plate 33 , the vibration plate 33 is connected to a linear feeder 32 , and the linear feeder 32 is connected to a positioning groove 31 .

[0025] As a preferred embodiment of the present invention, the vibrating plate 33 is provided with a hopper with a spiral track, and the vibrating plate 33 is also provided with an inclined spring piece and a pulse electromagnet, and the spring plate vibrates in the vertical direction through the pulse electromagnet to drive the hopper to perform torsional vibration.

[0026] As a preferred embodiment of the present invention, the positioning groove 31 is provided with a suction hole for sucking the rubber pad.

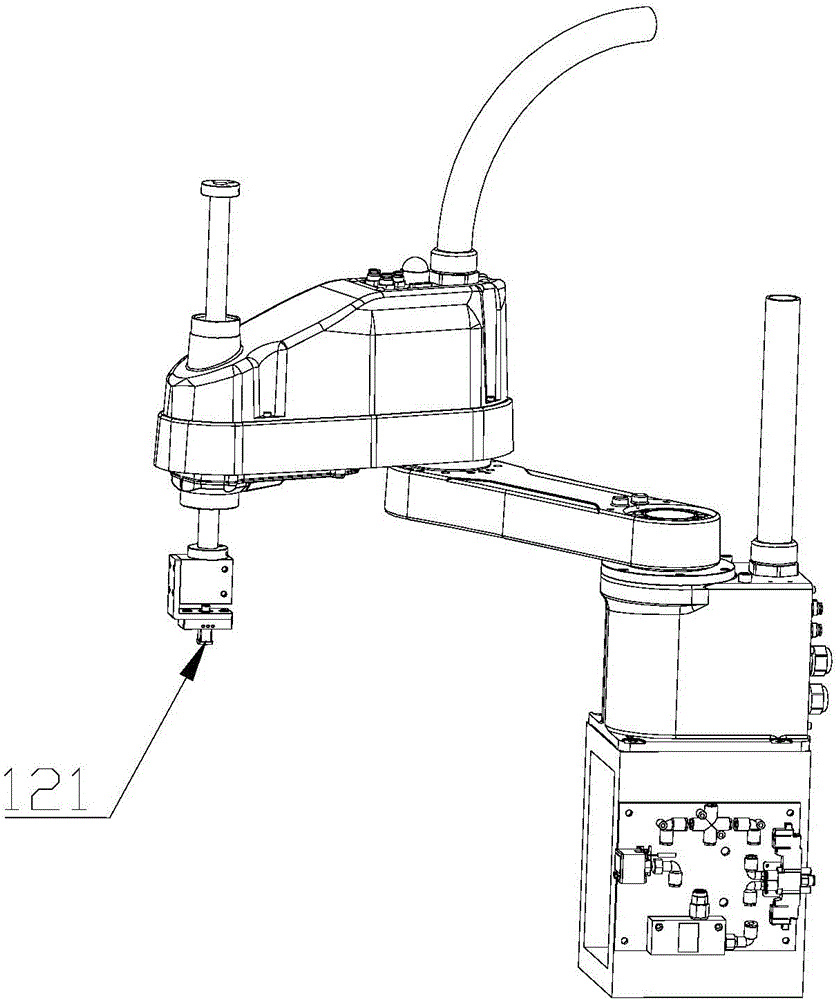

[0027] As a preferred embodiment of the present invention, the suction head mechanism 12 is provided with a suction head 121 .

[0028] As a preferred embodiment of the present invention, the suction head 121 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com