Metalized package electronic ceramic printing slurry and preparation method thereof

A technology for encapsulating electronics and ceramic printing, which is applied in the field of paste for printing metallized encapsulating electronic ceramics and its preparation, can solve the problems of weak surface tension, poor solderability, and weak surface force of joint ceramics, and achieve strong surface tension and surface Strong force and strong solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

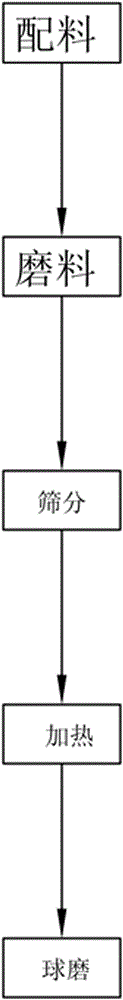

Image

Examples

Embodiment 1

[0023] Weigh the raw materials according to the weight percentage of the raw materials, molybdenum powder: 85%, manganese powder: 8%, porcelain powder: 7%, and mix them evenly; add the uniformly mixed raw materials to the centrifugal ball mill, and control the milling time at 60 hours ; Pass the ball-milled material through a 300-mesh sieve, and take the material under the sieve; heat the material under the sieve to 28°C, and then add a solvent that accounts for 6% of the material weight. The solvent is a mixture of terpineol and cellulose; The materials are put into a stirring ball mill for 48 hours under constant temperature stirring and ball milling to obtain metalized packaging electronic ceramic printing slurry.

Embodiment 2

[0025] Weigh the raw materials according to the weight percentages of the raw materials, molybdenum powder: 86%, manganese powder: 7%, porcelain powder: 7%, and mix them evenly; add the uniformly mixed raw materials to the centrifugal ball mill, and the milling time is controlled at 55 hours ; Pass the ball-milled material through a 300-mesh sieve and take the material under the sieve; heat the material under the sieve to 27°C, and then add a solvent that accounts for 6% of the weight of the material. The solvent is a mixture of terpineol and cellulose; The materials are put into a stirring ball mill for 48 hours under constant temperature stirring and ball milling to obtain metalized packaging electronic ceramic printing slurry.

Embodiment 3

[0027] Weigh the raw materials according to the weight percentages of the raw materials, molybdenum powder: 87%, manganese powder: 6%, porcelain powder: 7%, and mix them evenly; add the uniformly mixed raw materials to the centrifugal ball mill, and control the milling time at 50 hours ; Pass the ball-milled material through a 300-mesh sieve, and take the material under the sieve; heat the material under the sieve to 29°C, and then add a solvent that accounts for 6% of the weight of the material, and the solvent is a mixture of terpineol and cellulose; The materials are put into a stirring ball mill for 48 hours under constant temperature stirring and ball milling to obtain a metalized packaging electronic ceramic printing slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com